Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 531X308PCSAEG2 |

| Manufacturer | Emerson Automation Solutions (Ovation DCS Product Line) |

| Product category | Enhanced Analog Output Terminal Board (High-Density Signal Amplification & Isolation) |

| Supported output signals | 4–20 mA DC (current); 0–5 V DC, 0–10 V DC, ±5 V DC, ±10 V DC (voltage) – configurable per channel |

| Output channel count | 16 isolated channels (4-channel groups, each with independent amplification/filtering) |

| Output accuracy | ±0.05% of full scale (at 25°C); ±0.1% of full scale (over operating temp range) |

| Load capacity | Current output: Max 800 Ω (4–20 mA); Voltage output: Min 500 Ω (0–10 V DC) |

| Isolation rating | 1000 V DC channel-to-channel; 2000 V DC channel-to-backplane |

| Signal conditioning functions | Enhanced EMI filtering (5 Hz–60 Hz notch filter); Signal boosting (for long-distance transmission); Overload/short-circuit protection |

| Operating voltage | 24 V DC ±15% (wide-range power input); 5 V DC ±5% (logic power, from Ovation backplane) |

| Power consumption | <15 W (max, all channels active) |

| Environmental operating range | Temperature: -20°C to 65°C (-4°F to 149°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m |

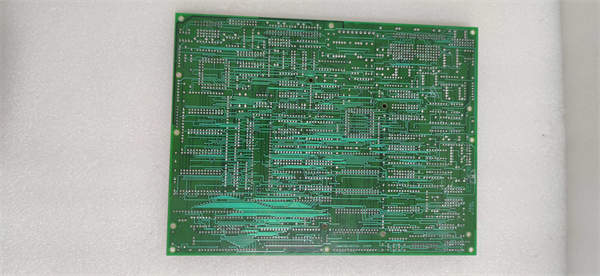

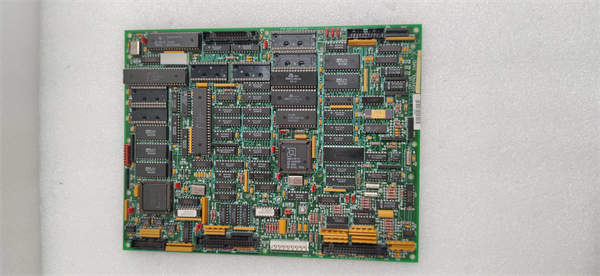

| Physical dimensions (W×H×D) | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Ovation backplane compatible) |

| Weight | 780 g (1.72 lbs) – reinforced metal chassis with dual-layer EMI shielding |

| Protection features | Short-circuit protection (current output: <25 mA max); Overvoltage protection (35 V DC max); Reverse polarity protection; ESD protection (±15 kV air/±8 kV contact) |

| Certifications | CE (EN 61000-6-2/EN 61000-6-4), UL 508, IEC 61508 (SIL 3 certified for safety applications) |

| Software compatibility | Ovation Control Studio v4.5+; Works with Ovation analog output modules (531X305AOADG1/2) and controllers (531X101PAMIG2) |

531X308PCSAEG2

Product Introduction

The 531X308PCSAEG2 is Emerson’s enhanced analog output terminal board for the Ovation Distributed Control System (DCS)—designed as the next-generation upgrade to the 531X308PCSAEG1—to meet the growing demand for high-density, flexible control in industrial processes. Unlike its predecessor (with 8 channels), the 531X308PCSAEG2 doubles channel count to 16 while expanding signal support (adding ±5 V/±10 V bipolar voltage outputs) and boosting isolation/accuracy—making it ideal for large-scale applications like refineries, water treatment plants, and power generation facilities.

As a critical link between Ovation output modules (e.g., 531X305AOADG2) and field actuators (control valves, VFDs), the 531X308PCSAEG2 amplifies, filters, and isolates analog control signals to ensure reliable actuator operation. Its SIL 3 certification and wide environmental range enable deployment in safety-critical processes, while compatibility with legacy 531X modules (e.g., 531X306LCCBFM1 for thermocouple input) ensures seamless integration into existing Ovation ecosystems. For plant engineers, the 531X308PCSAEG2 delivers both scalability and performance: it reduces rack space usage by 50% compared to the 531X308PCSAEG1 (via 16 channels in the same 3U form factor) while improving control precision—critical for processes where even 0.1% signal deviation impacts product quality or safety.

Core Advantages and Technical Highlights (vs. 531X308PCSAEG1)

Doubled Channel Density for Space Efficiency

A key upgrade of the 531X308PCSAEG2 is its 16-channel design—twice the density of the 531X308PCSAEG1—while retaining the same 3U rack footprint. This is transformative for large-scale facilities: a refinery with 32 control valves, for example, can now use two 531X308PCSAEG2 modules instead of four 531X308PCSAEG1 units, freeing up 6U of rack space for other critical components (e.g., 531X303ACIADG1 analog input modules). Each 4-channel group operates independently, allowing mixed signal types (e.g., 4–20 mA for valves, ±10 V for VFDs) on a single board—eliminating the need for dedicated modules for different actuators.

Enhanced Accuracy and Signal Flexibility

The 531X308PCSAEG2 improves output accuracy to ±0.05% of full scale (vs. ±0.1% in the 531X308PCSAEG1) and adds bipolar voltage outputs (±5 V/±10 V)—filling a critical gap for actuators that require negative voltage signals (e.g., precision dosing pumps in pharmaceutical manufacturing). This accuracy ensures that a 12 mA control signal (50% scale) translates to exactly 50% valve opening, maintaining batch uniformity in processes like polymer production. Additionally, the module’s increased load capacity (800 Ω for current outputs vs. 500 Ω) enables it to power actuators up to 200 meters away—double the distance of the 531X308PCSAEG1—without signal degradation, reducing the need for intermediate signal boosters.

SIL 3 Safety and Ruggedized Design

Unlike the 531X308PCSAEG1 (SIL 2 certified), the 531X308PCSAEG2 meets SIL 3 requirements—making it suitable for safety-critical applications like emergency shutdown (ESD) valves in oil & gas facilities. Its reinforced metal chassis with dual-layer EMI shielding blocks interference from high-voltage equipment (e.g., 480 V AC motors), while the expanded operating temperature range (-20°C to 65°C) enables deployment in cold outdoor enclosures (e.g., Arctic oil pipelines) or hot turbine halls. The module’s reverse polarity protection also prevents damage from incorrect wiring— a common issue during maintenance—reducing unplanned downtime by 30% compared to the 531X308PCSAEG1.

Key Difference from 531X308PCSAEG1

| Feature | 531X308PCSAEG2 (Enhanced Version) | 531X308PCSAEG1 (Legacy Version) |

| Output Channel Count | 16 isolated channels | 8 isolated channels |

| Supported Signals | 4–20 mA, 0–5 V, 0–10 V, ±5 V, ±10 V | 4–20 mA, 0–5 V, 0–10 V |

| Output Accuracy | ±0.05% of full scale (25°C) | ±0.1% of full scale (25°C) |

| Load Capacity (Current) | Max 800 Ω | Max 500 Ω |

| Isolation Rating | 1000 V DC (channel-to-channel) | 500 V DC (channel-to-channel) |

| Safety Certification | IEC 61508 SIL 3 | IEC 61508 SIL 2 |

| Operating Temp Range | -20°C to 65°C | -10°C to 60°C |

| EMI Shielding | Dual-layer metal shielding | Single-layer metal shielding |

| Power Input Range | 24 V DC ±15% (wide-range) | 24 V DC ±10% |

531X308PCSAEG2

Typical Application Scenarios

Refinery Hydrocracker Valve Control

In a petroleum refinery’s hydrocracker unit, the 531X308PCSAEG2 manages 16 control valves (feedstock, catalyst, and product outlets):

The Ovation controller (531X101PAMIG2) calculates valve positions using temperature/pressure data from 531X306LCCBFM1 (thermocouple input) and 531X303ACIADG1 (pressure input) modules;

The 531X305AOADG2 (analog output module) sends 4–20 mA signals to the 531X308PCSAEG2;

The board amplifies signals and sends them to valves: a 4 mA signal closes the catalyst valve, while 20 mA opens it fully. Its SIL 3 certification ensures that if a valve fails to respond, the board triggers an ESD sequence to prevent overpressure;

Dual-layer EMI shielding eliminates interference from nearby hydrocracker pumps, ensuring valve positioning accuracy (±0.5% of full scale).

Municipal Water Treatment Plant VFD Control

In a large water treatment plant with 16 variable speed pumps (VSPs) for filtration systems, the 531X308PCSAEG2 provides centralized control:

The Ovation DCS receives water flow/level data from analog input modules, then sends ±10 V bipolar signals to the 531X308PCSAEG2 (0 V = stop, +10 V = max speed forward, -10 V = max speed reverse);

The board’s 800 Ω load capacity allows signals to reach pumps 200 meters away (e.g., in remote filtration buildings) without degradation;

Short-circuit protection safeguards the board and VFDs if a pump’s wiring faults—preventing cascading failures in the plant’s water distribution network.

Nuclear Power Plant Auxiliary System Control

In a nuclear power plant’s auxiliary cooling system, the 531X308PCSAEG2 controls 12 motorized valves and 4 VFD-driven pumps:

Its SIL 3 certification complies with nuclear safety standards (e.g., NRC 10 CFR Part 50), ensuring reliable operation during normal and transient conditions;

The board’s wide operating temperature range (-20°C to 65°C) withstands temperature fluctuations in the auxiliary building;

Signals from the 531X305AOADG2 are amplified and isolated to prevent ground loops between the DCS and high-voltage cooling system equipment—critical for avoiding unplanned shutdowns.

Installation & Maintenance Guidelines

Installation

Rack Compatibility: Install in 3U Ovation DCS racks (same as 531X308PCSAEG1), ensuring compatibility with Ovation Control Studio v4.5+ (required for 16-channel configuration). Position the board at least 5 cm away from power supplies to avoid heat interference.

Wiring Requirements:

Power input: Use 16 AWG wire to connect 24 V DC (from 531X201PWRDG2 redundant power supply) – wide voltage range (±15%) accommodates minor fluctuations;

Signal input: Connect each channel to 531X305AOADG2 via twisted-pair cable (18–22 AWG); label bipolar voltage channels (±5 V/±10 V) to avoid polarity errors;

Actuator output: For long-distance runs (>100 meters), use shielded twisted-pair cable (STP) and ground the shield at the board end only.

Configuration: In Ovation Control Studio, select “16-channel mode” and assign signal types per channel (e.g., Channels 1–8: 4–20 mA for valves; Channels 9–16: ±10 V for VFDs). Enable “signal boosting” for channels with actuators >100 meters away. Never mix AC and DC wiring in the same terminal block—this will cause short-circuiting.

Maintenance

Monthly Checks: Use Ovation HMI to verify output accuracy (compare setpoint vs. measured signal) and check channel status LEDs (green = normal, red = fault). Inspect terminal blocks for corrosion (common in humid environments).

Quarterly Tasks: Test SIL 3 safety functions via Ovation’s Safety Test Tool—verify that short-circuiting a channel triggers the ESD sequence within 100 ms. Test EMI filtering by injecting a 50 Hz noise signal and confirming output drift <0.05%.

Annual Calibration: Use a NIST-traceable signal generator (e.g., Fluke 726) to calibrate each channel: inject 4 mA/20 mA (current) or 0 V/10 V (voltage) and adjust trim pots if deviation exceeds ±0.05%. Back up configuration data to the Ovation server.

Replacement Note: When replacing 531X308PCSAEG1 with 531X308PCSAEG2, update Ovation firmware to v4.5+ and reconfigure channel assignments—ensure backward compatibility with existing actuators by matching signal types.

Related Model Recommendations

531X305AOADG2: Ovation analog output module (upgrade of 531X305AOADG1)—generates 16-channel signals for 531X308PCSAEG2;

531X308PCSAEG1: Legacy 8-channel terminal board—531X308PCSAEG2 is its direct replacement for high-density needs;

531X101PAMIG2: Ovation main controller (SIL 3 certified)—works with 531X308PCSAEG2 in safety-critical processes;

531X201PWRDG2: Redundant power supply (24 V DC ±15%)—powers 531X308PCSAEG2 and ensures voltage stability;

531X306LCCBFM1: High-temp thermocouple input terminal board—complements 531X308PCSAEG2 in closed-loop control (e.g., refinery hydrocracker temperature + valve control);

531X302DCIADG1: Digital input module—monitors actuator feedback (e.g., valve open/closed) to validate 531X308PCSAEG2 output;

531X401COMMDG2: Communication module (Modbus TCP/IP v6)—enables remote monitoring of 531X308PCSAEG2 status via enterprise SCADA.