Description

Product Overview

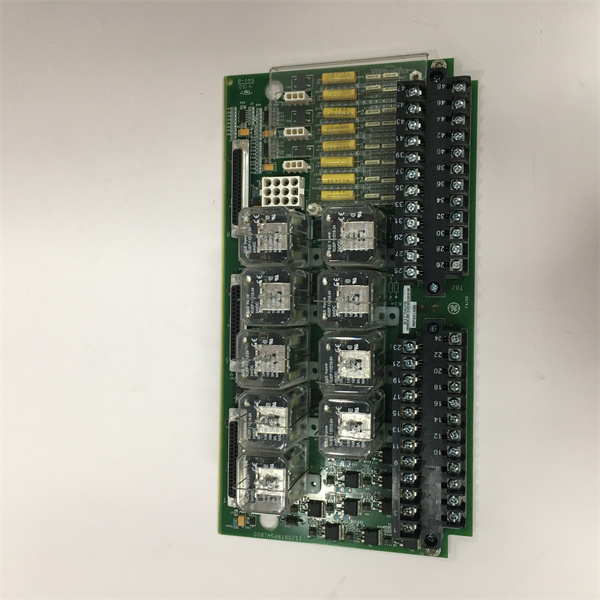

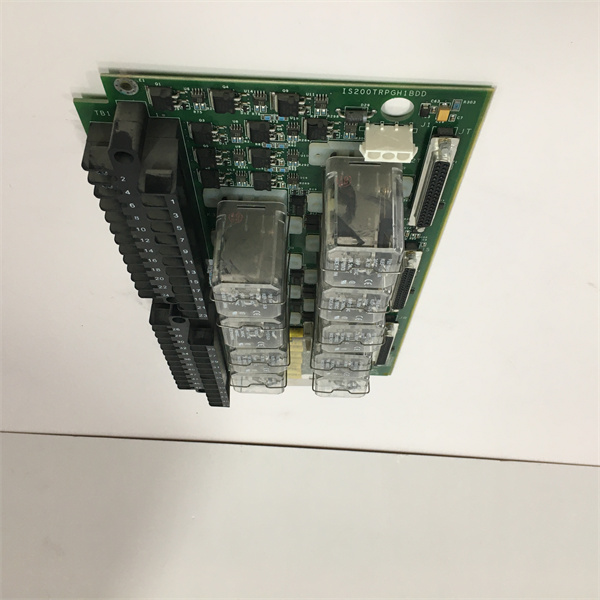

The GE CR453CE2HBB is a high – performance control module meticulously crafted by General Electric for industrial automation systems. It serves as a linchpin in ensuring the seamless operation of various industrial processes, providing reliable performance and precision across a diverse range of industrial environments, including manufacturing plants and power generation facilities.

This module is engineered to handle a variety of control tasks. It can regulate and monitor industrial operations with great accuracy. For instance, it might be used to control the speed of motors, adjust the flow of fluids in pipelines, or manage the temperature in industrial ovens. The CR453CE2HBB is designed to integrate smoothly into existing industrial setups, enhancing the overall efficiency of the automation system. Its advanced design and capabilities make it an essential component for industries that demand high – quality control solutions to optimize their production processes and ensure consistent product quality.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | CR453CE2HBB |

| Manufacturer | General Electric |

| Product Type | Control Module |

| Voltage Rating | 24 V DC |

| Current Rating | 1 A |

| Communication Protocol | Modbus RTU, supports Ethernet/IP and DeviceNet |

| Operating Temperature Range | – 20 °C to + 60 °C |

| Environmental Protection Rating | IP65 |

| Dimensions | 150 mm x 100 mm x 40 mm |

| Weight | 0.5 kg |

| Input/Output Range | Input: MA 224; Output: MA 122 (may vary by application) |

Main Features and Advantages

Reliable Performance: Built with high – quality components, the GE CR453CE2HBB offers reliable operation even in harsh industrial conditions. Its sturdy construction can withstand vibrations, dust, and temperature fluctuations, ensuring consistent performance over time.

Advanced Communication Capabilities: With support for multiple communication protocols such as Modbus RTU, Ethernet/IP, and DeviceNet, it can easily communicate and integrate with other devices and systems in the industrial network. This seamless communication allows for real – time data transfer and control, enhancing the overall system efficiency.

Precise Control: Engineered to provide precise regulation and monitoring, it enables accurate control over industrial processes. Whether it’s adjusting the speed of machinery or controlling the dosage of chemicals in a process, the CR453CE2HBB ensures that operations are carried out with a high degree of precision, minimizing errors and improving product quality.

Compact and Lightweight Design: Its compact size and lightweight nature make installation easy and space – efficient. This design feature allows for flexible deployment in various industrial settings, whether in a large manufacturing plant or a smaller industrial unit where space might be at a premium.

Advanced Communication Capabilities: With support for multiple communication protocols such as Modbus RTU, Ethernet/IP, and DeviceNet, it can easily communicate and integrate with other devices and systems in the industrial network. This seamless communication allows for real – time data transfer and control, enhancing the overall system efficiency.

Precise Control: Engineered to provide precise regulation and monitoring, it enables accurate control over industrial processes. Whether it’s adjusting the speed of machinery or controlling the dosage of chemicals in a process, the CR453CE2HBB ensures that operations are carried out with a high degree of precision, minimizing errors and improving product quality.

Compact and Lightweight Design: Its compact size and lightweight nature make installation easy and space – efficient. This design feature allows for flexible deployment in various industrial settings, whether in a large manufacturing plant or a smaller industrial unit where space might be at a premium.

Application Field

In the manufacturing industry, the GE CR453CE2HBB is widely used. For example, in an automotive manufacturing plant, it can control the movement of robotic arms on the assembly line, ensuring that parts are assembled accurately and efficiently. It can also manage the operation of conveyor belts, regulating their speed to match the production pace.

Power generation facilities also benefit significantly from this module. In a power plant, it can monitor and control the operation of turbines. By regulating parameters such as steam flow and temperature, it helps to optimize the power generation process, ensuring stable and efficient energy production.

In the food and beverage industry, the CR453CE2HBB can be used to control the filling and packaging processes. It can precisely control the amount of liquid filled into bottles or the weight of packaged food products, maintaining strict quality standards.

Related Products

- GE CR453AD2HBB: A definite – purpose contactor. It has different contact ratings and applications compared to the CR453CE2HBB. While the CR453CE2HBB is a control module for overall process regulation, the CR453AD2HBB is more focused on switching electrical loads in applications like air conditioning, heating, and refrigeration systems.

- GE IS420PPNGH1A: A Profinet gateway module. Unlike the CR453CE2HBB which is centered on control functions, the IS420PPNGH1A is designed for facilitating communication between different systems in an industrial network, specifically for connecting Mark VIe controllers to Profinet I/O devices.

- GE IC697CPX772: A CPU module. It has a more powerful processing role in a PLC system compared to the CR453CE2HBB. The IC697CPX772 can handle complex logic operations and large – scale data processing, while the CR453CE2HBB is more about local control and monitoring of specific industrial processes.

- GE 453AD2HA: Another contactor in GE’s product line. It has different electrical ratings and coil voltages than the CR453CE2HBB. It is used for switching electrical circuits in industrial applications, whereas the CR453CE2HBB is more about providing control and regulation functions.

- GE IS420ESWAH1A: A high – speed counter module. Its main function is to accurately count high – speed events, such as pulses from sensors. This is different from the CR453CE2HBB which is mainly involved in control and monitoring of industrial processes rather than event counting.

Installation and Maintenance

Pre – installation preparation: Before installing the GE CR453CE2HBB, ensure that the power supply to the system is turned off to prevent electrical accidents. Inspect the module for any visible signs of damage, such as cracks in the casing or bent connectors. Verify that the installation environment meets the module’s requirements, with a temperature range between – 20 °C and + 60 °C and an IP65 – compliant enclosure to protect against dust and water ingress. Also, check the compatibility of the module with other components in the industrial automation system, including communication cables and other connected devices.

Maintenance recommendations: Regularly monitor the operational status of the CR453CE2HBB through the system’s diagnostic tools. Check for any abnormal behavior, such as incorrect control outputs or communication errors. Clean the module periodically to remove dust and debris, especially in dusty industrial environments. Since it operates in a wide temperature range, ensure that the cooling mechanisms (if any) are functioning properly. If any issues are detected, refer to the GE – provided manuals for detailed troubleshooting steps. In case of complex problems, contact GE’s technical support for expert assistance to maintain the module’s optimal performance.

Product Guarantee

GE stands firmly behind the quality of the GE CR453CE2HBB control module. It typically comes with a standard one – year warranty, covering defects in materials and workmanship under normal usage conditions. In the unlikely event that any issues arise within this period, GE’s dedicated technical support team is readily available. They can provide comprehensive assistance, from helping with installation guidance and configuration advice to troubleshooting operational problems. This commitment reflects GE’s confidence in the product’s durability and performance, giving customers peace of mind when integrating the CR453CE2HBB into their critical industrial automation systems.