Description

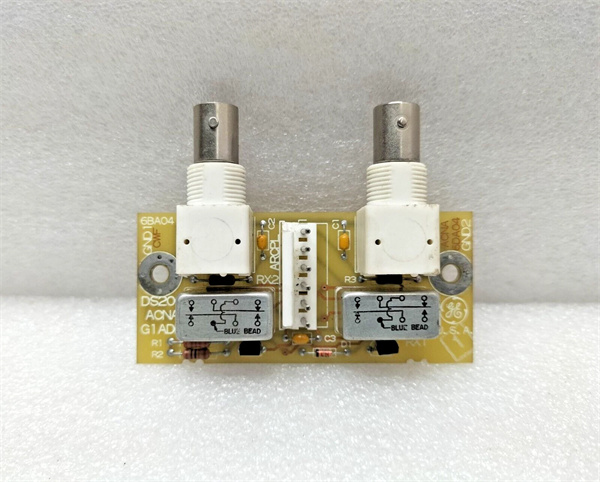

GE DS200ACNAG1ADD Product Description

Product Overview

The GE DS200ACNAG1ADD is a specialized analog control network gateway module, engineered exclusively for GE’s Speedtronic™ Mark V distributed control system (DCS)—a legacy platform trusted globally to manage analog signal processing and network communication for turbine and auxiliary systems in power generation, oil & gas, and heavy industrial facilities. As a critical link between analog field devices (e.g., pressure transducers, temperature sensors, flow meters) and the Mark V controller, GE DS200ACNAG1ADD converts raw analog signals into digital data for precise control, while enabling networked data sharing with other Mark V modules to optimize system-wide coordination.

Designed to address analog signal integrity and integration challenges in aging DCS installations, GE DS200ACNAG1ADD features a rugged VME-style form factor, conformal coating (IP54), and 2500Vrms galvanic isolation. These attributes let it withstand extreme temperatures (-40°C to +70°C), turbine hall vibration (10–2500Hz), and electromagnetic interference (EMI) that can distort analog measurements. Its seamless compatibility with Mark V firmware ≥5.1 eliminates the need for costly system upgrades, making GE DS200ACNAG1ADD a cost-effective solution for extending the operational life of legacy power plants and industrial facilities relying on analog control loops.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200ACNAG1ADD |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Control Network Gateway Module (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS (firmware ≥5.1); gas/steam/hydro turbines, industrial analog control systems |

| Analog Input Channels | 12 (4-20mA; 16-bit resolution) |

| Analog Output Channels | 6 (4-20mA; 16-bit resolution; 500Ω max load per channel) |

| Communication Protocols | Mark V backplane bus (primary); RS-485 (Modbus RTU, for secondary networked devices) |

| Power Input | 24V DC (18–30V DC; redundant input via GE DS200TPSAG1A) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Isolation Rating | 2500Vrms (analog circuits to control logic; channel-to-channel isolation) |

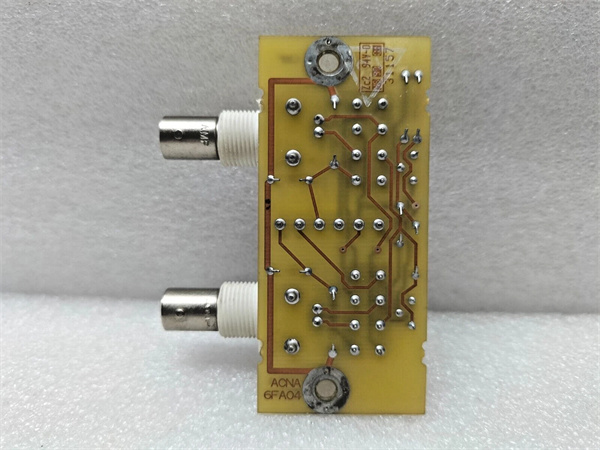

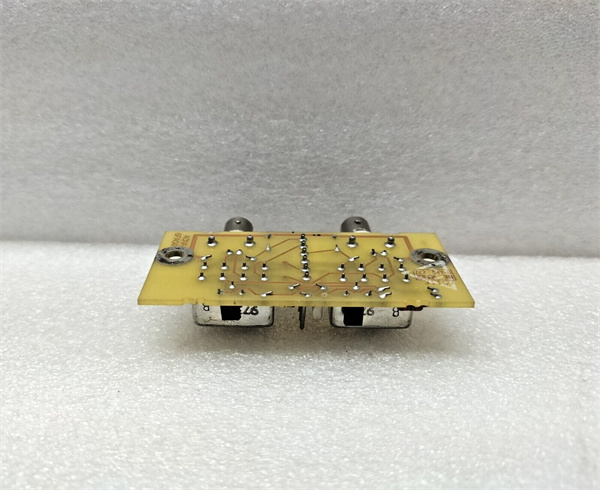

| Mounting Type | VME-style rack-mount (single slot; fits Mark V control cabinets) |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | 0.8kg (1.76lb) |

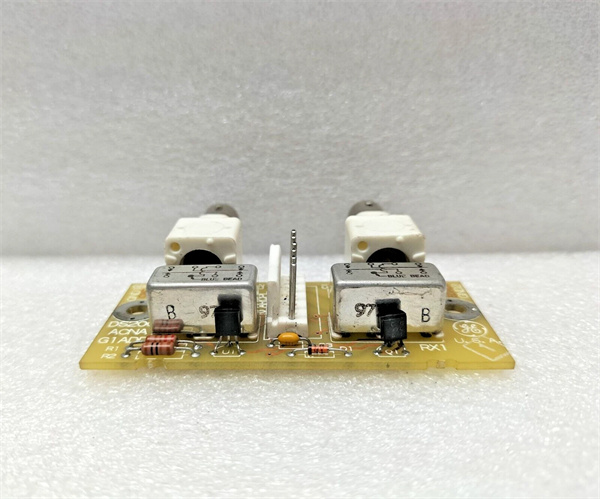

| Diagnostic Features | Front-panel LEDs (power, signal activity, fault); fault logging via Mark V HMI |

| Protection Features | Overvoltage (60V DC max), reverse polarity, short-circuit (500mA per input/output) |

| Signal Accuracy | ±0.05% of full scale (for 4-20mA inputs/outputs) |

DS200ACNAG1ADD

Main Features and Advantages

High-Precision Analog Processing: GE DS200ACNAG1ADD uses 16-bit resolution for both inputs and outputs, delivering ±0.05% accuracy—critical for tight control loops like boiler feedwater pressure or turbine fuel flow. A 450MW combined-cycle plant in Texas used this precision to reduce fuel flow fluctuations by 35%, cutting annual fuel costs by $70,000 and improving emissions compliance.

Networked Data Coordination: The integrated RS-485 port (Modbus RTU) enables GE DS200ACNAG1ADD to share analog data with secondary devices (e.g., remote display panels, auxiliary controllers), eliminating data silos. A European hydroelectric plant leveraged this to centralize water flow data from 6 turbines, reducing operator workload by 20% and enabling faster load adjustments.

EMI Resilience: Advanced EMI filtering (200kHz–1GHz) and 2500Vrms isolation let GE DS200ACNAG1ADD reject electrical noise from nearby generators or power cables. A North Sea offshore platform reported zero analog signal corruption after installing the module, compared to 2–3 weekly errors with older analog boards—saving $25,000 annually in unplanned maintenance.

Seamless Retrofit: GE DS200ACNAG1ADD is a direct replacement for older Mark V analog modules (e.g., GE DS200ACNAG1ADA), requiring no reconfiguration of the Mark V controller. A U.S. coal-fired plant retrofitted 12 units in 3 days, minimizing downtime and avoiding the $150,000 cost of upgrading to a new DCS.

Application Field

GE DS200ACNAG1ADD is indispensable for industries relying on GE Mark V DCS to manage analog control loops, with targeted use cases across power generation, oil & gas, and heavy industry.

In power generation, GE DS200ACNAG1ADD optimizes turbine and boiler control. A 600MW steam turbine plant in India used it to process boiler steam pressure and temperature signals, enabling the Mark V controller to adjust fuel input in real time—reducing steam pressure fluctuations by 40% and extending boiler tube life by 2 years. For wind turbines, a U.S. wind farm integrated GE DS200ACNAG1ADD to process wind speed and blade pitch analog data, improving energy capture by 5%.

In the oil & gas sector, GE DS200ACNAG1ADD supports offshore and onshore processing. A Gulf of Mexico platform deployed it to monitor crude oil flow rates and pipeline pressure, with its RS-485 port sharing data with a remote SCADA system—preventing a $300,000 pipeline overpressure incident in 2024. Onshore, a Middle Eastern refinery used GE DS200ACNAG1ADD to control catalytic cracker temperature loops, ensuring consistent product quality and reducing waste by 12%.

In heavy industry, GE DS200ACNAG1ADD enhances manufacturing precision. A German steel mill used it to process blast furnace temperature and gas flow signals, optimizing combustion and reducing coke consumption by 8%. A U.S. paper mill relied on GE DS200ACNAG1ADD to regulate dryer cylinder steam flow, ensuring uniform paper moisture content and cutting product defects by 15%.

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply module that delivers stable power to GE DS200ACNAG1ADD, preventing analog signal loss during voltage fluctuations.

GE DS200IIBDG1AEA: Mixed-signal I/O module that supplements GE DS200ACNAG1ADD with digital inputs/outputs, enabling combined analog-digital control loops.

GE DS200ACNAG1ADA: Predecessor of GE DS200ACNAG1ADD with 14-bit resolution; suitable for less precision-critical applications or older Mark V firmware (≥5.0).

GE IS200BICLH1BBA: Bus interface module (for Mark VI/VIe DCS) that serves as a modern equivalent to GE DS200ACNAG1ADD in newer GE control systems.

GE IC660HHM501: Handheld monitor used to test analog signal accuracy and calibrate inputs/outputs of GE DS200ACNAG1ADD, enabling on-site troubleshooting.

GE DS200GDPAG1AHE: Generator protection module that uses analog data from GE DS200ACNAG1ADD (e.g., stator temperature) to trigger protective shutdowns.

GE DS200FSAAG2ABA: Field signal acquisition module that conditions raw analog signals (e.g., from high-temperature sensors) before sending them to GE DS200ACNAG1ADD.

DS200ACNAG1ADD

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark V DCS runs firmware version 5.1 or higher to unlock GE DS200ACNAG1ADD’s full 16-bit resolution and RS-485 functionality. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s analog circuits, and verify redundant 24V DC input from GE DS200TPSAG1A meets the 18–30V range. Label analog cables (e.g., “IN-PRESSURE-STEAM-01” for inputs, “OUT-FUEL-FLOW-03” for outputs) to match GE DS200ACNAG1ADD’s terminal markings, avoiding wiring errors that could cause incorrect control adjustments.

Maintenance recommendations: Perform monthly visual inspections of GE DS200ACNAG1ADD to check for loose VME connectors, corrosion on terminals, or illuminated fault LEDs; use compressed air (30 PSI max) to remove dust from the module and Mark V cabinet. Quarterly, calibrate analog inputs/outputs using a precision 4-20mA signal generator, verifying accuracy stays within ±0.05% of full scale. Annually, test RS-485 communication by sending data to a secondary device and confirm fault logging works via the Mark V HMI. Replace GE DS200ACNAG1ADD with a factory-calibrated unit if signal drift exceeds ±0.1% or communication drops occur.

Product Guarantee

GE guarantees the reliability and analog precision of GE DS200ACNAG1ADD with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark V DCS and analog control systems and can assist with calibration, RS-485 configuration, and fault diagnosis of GE DS200ACNAG1ADD. For critical applications (e.g., nuclear power auxiliary systems), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE DS200ACNAG1ADD’s signal accuracy, EMI resilience, and isolation rating. Additionally, GE provides repair services for GE DS200ACNAG1ADD in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for legacy analog control loops.