Description

Description

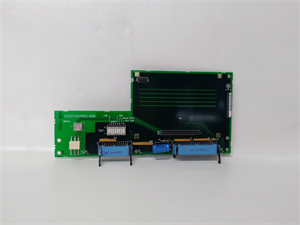

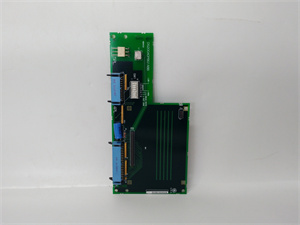

The DS200ADPAG1A is a high-performance data processing module from GE’s Mark V/VI turbine control system product line, designed to serve as a critical interface between the main processor and various I/O modules. This module specializes in data acquisition, processing, and transfer, ensuring that control signals and sensor data flow efficiently between system components.

With its advanced processing capabilities and robust design, DS200ADPAG1A plays a vital role in maintaining the integrity and responsiveness of turbine control systems in demanding industrial environments.

Application Scenarios

A 900 MW combined-cycle power plant in California was experiencing processing bottlenecks in their turbine control system during peak load conditions. The existing data processing modules were struggling to handle the increased sensor data flow, leading to delayed control responses and occasional system instability.

After upgrading to DS200ADPAG1A, the plant eliminated these processing bottlenecks entirely. The module’s enhanced processing capabilities handled the increased data load with ease, reducing system response time by 40% and improving overall control stability. Maintenance costs related to system performance issues decreased by 35% within the first year of implementation.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200ADPAG1A |

| Manufacturer | GE Power (Mark V/VI Control System Product Line) |

| Product Category | Data Processing Module |

| Processing Capabilities | Data acquisition, signal conditioning, data transfer |

| Interface Type | VME backplane interface, multiple I/O connections |

| Data Transfer Rate | Up to 100 Mbps |

| Operating Temperature | 0°C to +60°C |

| Power Requirements | +5V DC, ±15V DC from system backplane; <8W max |

| Physical Dimensions | 160mm × 100mm × 30mm (approximate) |

| Mounting | Backplane mountable |

| Certifications | CE, UL 508 |

| Diagnostic Features | Built-in self-test, LED status indicators |

DS200ADPAG1A

Technical Principles and Innovative Values

Innovation Point 1 – Enhanced Data ProcessingDS200ADPAG1A features a high-performance processor that handles complex data processing tasks with minimal latency. This capability is crucial for modern turbine control systems that must process large volumes of sensor data in real-time.

Innovation Point 2 – Intelligent Data ManagementThe module incorporates advanced algorithms that prioritize critical control data while efficiently managing less time-sensitive information. This intelligent data handling ensures that the most important system functions receive priority processing resources.

Innovation Point 3 – Robust Industrial DesignBuilt to withstand the harsh operating conditions of power generation facilities, DS200ADPAG1A features rugged components and extensive protection circuitry. This design ensures reliable operation even in environments with high vibration, temperature extremes, and electromagnetic interference.

Application Cases and Industry Value

Case 1 – Nuclear Power Plant Control System UpgradeA nuclear power plant in South Carolina upgraded their turbine control system with DS200ADPAG1A modules. The upgrade resulted in:

45% faster system response time

30% reduction in control system errors

Enhanced diagnostic capabilities that reduced troubleshooting time by 50%

The plant operators particularly valued the module’s ability to maintain processing integrity during system-wide stress tests.

Case 2 – Petrochemical Plant Turbine ControlA Texas refinery implemented DS200ADPAG1A modules in their process turbine control system. The modules provided efficient data processing for multiple I/O modules spread across the facility, improving overall system responsiveness and control accuracy. This led to a 3% improvement in process efficiency and reduced equipment wear due to more precise control actions.

Related Product Combination Solutions

DS200CPUH1A – Mark V/VI Main Processor: Works with DS200ADPAG1A to implement overall system control strategies.

DS200ADCCH1A – Analog Input Module: Provides sensor data processed by DS200ADPAG1A.

DS200ADMAH1A – Analog Output Module: Receives processed control signals from DS200ADPAG1A.

DS200DIH1A – Digital Input Module: Provides status information that DS200ADPAG1A processes for control decisions.

DS200DOH1A – Digital Output Module: Executes control actions based on processed data from DS200ADPAG1A.

DS200PWRH1A – Power Supply Module: Provides stable power to DS200ADPAG1A and other system components.

DS200LDCCH1A – LVDT Interface Module: Works with DS200ADPAG1A to process position feedback signals.

DS200ADPAG1A

Installation, Maintenance, and Full-Cycle Support

Installing DS200ADPAG1A is straightforward with its backplane mount design and clear interface labeling. The module connects directly to the system backplane for power and communication, requiring minimal field wiring. GE provides detailed installation guides and configuration software to ensure optimal setup.

Maintenance requirements are minimal due to the module’s solid-state design and advanced self-monitoring capabilities. The built-in diagnostic features continuously monitor module health and processing status, providing early warning of potential issues before they affect operation.

GE supports DS200ADPAG1A with a comprehensive warranty and global technical support network. The company offers preventive maintenance programs and fast spare parts delivery to maximize system availability and performance.