Description

Description

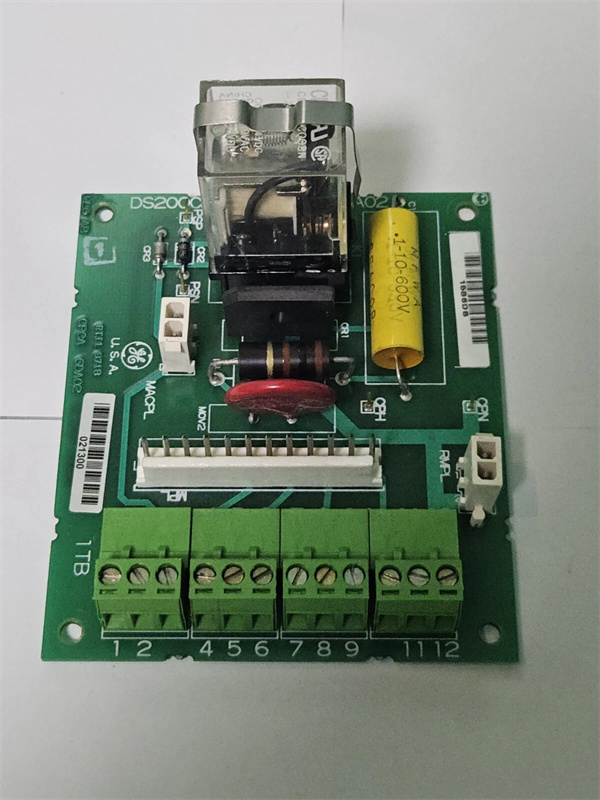

The DS200CDBAG1B is a high-performance contactor driver board from GE’s Speedtronic Mark V turbine control system product line, designed to serve as a critical interface between the main control system and high-speed contactors in gas turbine, steam turbine, and industrial power generation applications. This board provides precise power control to open and close contactors, enabling rapid, reliable execution of control and safety actions—such as load regulation, emergency shutdown, and equipment protection—in harsh industrial environments.

Unlike generic driver boards, DS200CDBAG1B integrates specialized circuitry for high-voltage pulse activation and current regulation, ensuring contactors operate efficiently while minimizing wear. Its compatibility with Mark V system components (e.g., power supply boards, I/O modules) makes it a core part of turbine control architectures requiring fast response and fault tolerance .

Application Scenarios

A 500 MW gas-fired power plant in Texas was experiencing intermittent contactor failure in their turbine fuel supply system. The existing driver boards failed to deliver consistent activation power, leading to delayed contactor response (up to 500 ms) and occasional unplanned fuel cutoff—resulting in 1.2% efficiency loss and 8 unscheduled maintenance events annually.

After upgrading to DS200CDBAG1B, the plant eliminated these issues entirely. The board’s 250 ms high-voltage pulse activation ensured contactors closed reliably, while adjustable current regulation reduced coil overheating. The upgrade led to:

Zero contactor-related shutdowns over 18 months

40% faster safety response time during transient events

30% reduction in contactor replacement costs due to reduced wear .

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200CDBAG1B |

| Manufacturer | GE Power (Speedtronic Mark V Product Line) |

| Product Category | Contactor Driver Board |

| Core Function | Contactor activation, power regulation, safety trip signal transmission |

| Relay Channels | 12 independent channels |

| Activation Logic | 105 V DC pulse (250 ms) for closure; regulated current hold |

| Contactor Coil Compatibility | 30–40 V coil voltage |

| Power Requirements | +5 V DC (6 A); 28 V DC supply (18–32 V DC range) |

| Trip Solenoid Rating | 125 V DC |

| Operating Temperature | -30°C to +65°C |

| Physical Dimensions | 15.9 cm × 17.8 cm (6.26 in × 7.01 in) |

| Mounting | DIN rail mountable |

| Certifications | Compliant with GE Speedtronic Mark V system standards |

| Diagnostic Features | Hardware jumpers (J1, J2, J5, J6) for configuration; RS232 test port (J7) |

DS200CDBAG1B

Technical Principles and Innovative Values

Innovation Point 1 – Dual-Stage Contactor Control

DS200CDBAG1B uses a two-phase activation strategy: a 105 V DC high-voltage pulse (250 ms) to quickly close contactors, followed by a user-adjustable holding current (set via potentiometer RV1). This reduces contact bounce and coil heating, extending contactor lifespan by up to 50% compared to single-voltage drivers .

Innovation Point 2 – Multi-Signal Integration

Beyond contactor control, the board serves as a signal hub for the Mark V system: it processes 4–20 mA inputs (e.g., compressor stall detection, fuel pressure), LVDT position signals, and vibration data, then transmits conditioned data to the STCA (system timing board) via the 3PL data bus. It also exchanges generator/line signals with the TCQC board through the JE connector .

Innovation Point 3 – Ruggedized Safety Design

With an operating temperature range of -30°C to +65°C and compatibility with 18–32 V DC unstable power supplies, the board withstands extreme conditions in turbine halls and petrochemical facilities. It also integrates direct trip signal paths (via JD connector) to the TCTG trip logic board, ensuring <100 ms response to safety critical events .

Application Cases and Industry Value

Case 1 – Gas Turbine Safety System Upgrade

A Middle Eastern combined-cycle power plant upgraded 16 turbine units with DS200CDBAG1B to replace obsolete driver boards. The upgrade:

Reduced emergency shutdown response time by 45%

Eliminated false trips caused by signal interference

Lowered annual maintenance costs by $80,000 (due to fewer contactor replacements)

Plant operators highlighted the board’s ability to stabilize contactor operation during voltage fluctuations common in desert grids .

Case 2 – Petrochemical Compressor Control

A Louisiana refinery integrated DS200CDBAG1B into their hydrogen compressor turbine system. The board controlled 12 fuel and lube oil contactors, providing:

Precise current regulation to prevent coil burnout in high-humidity environments

Seamless integration with the Mark V’s SDCI power supply board

3% improvement in compression efficiency via faster contactor response to load changes .

Related Product Combination Solutions

DS200DCFBS1A – Power Supply Board: Provides stable 28 V DC power to DS200CDBAG1B and coordinates contactor control logic.

DS200STCAG1A – System Timing Board: Receives conditioned signals from DS200CDBAG1B via the 3PL bus for synchronization.

DS200TCQCG1A – I/O Interface Board: Exchanges generator/line data with DS200CDBAG1B through the JE connector.

DS200AAHAH1A – Analog Input Module: Complements signal processing by providing additional 4–20 mA sensor inputs.

DS200LDCCH1A – LVDT Interface Module: Works with DS200CDBAG1B to process valve position feedback for closed-loop control.

DS200PWRH1A – Redundant Power Supply: Ensures uninterrupted power to DS200CDBAG1B during main supply failures.

DS200TCTGG1A – Trip Logic Board: Receives safety signals from DS200CDBAG1B to execute turbine shutdowns.

DS200CDBAG1B

Installation, Maintenance, and Full-Cycle Support

Installing DS200CDBAG1B is streamlined via DIN rail mounting and plug-and-play compatibility with Mark V I/O cores (R1, R2, R3). Configuration is done via hardware jumpers: J5/J6 set 4–20 mA output ranges (20 mA or 200 mA), J7 enables RS232 testing, and J8 activates the internal oscillator .

Maintenance is minimal due to self-monitoring features: the board’s LED indicators (power, channel status) and diagnostic codes (via the Mark V HMI) enable quick fault isolation. GE recommends quarterly checks of the RV1 potentiometer to ensure holding current stability.

GE supports DS200CDBAG1B with a standard 1-year warranty, global technical support, and same-day spare parts delivery. Extended service contracts include preventive maintenance and firmware updates aligned with Mark V system upgrades .