Description

GE DS200CTBAG1ADD Product Description

Product Overview

The GE DS200CTBAG1ADD is a standard-version control and status monitoring module, specifically engineered for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry backbone in industrial power generation, regional utilities, and medium-scale energy facilities managing gas, steam, and combined-cycle turbines. As a “centralized management hub” for turbine key auxiliary subsystems, GE DS200CTBAG1ADD undertakes three core roles: executing integrated control logic for critical auxiliary systems (e.g., fuel pressure regulation, steam temperature control, and bearing lubrication flow adjustment), realizing multi-dimensional status monitoring of turbine key components (e.g., real-time tracking of bearing temperature, rotor vibration, and seal oil pressure), and providing early warning of abnormal operating states (e.g., triggering alerts when bearing temperature exceeds 80°C or vibration amplitude exceeds 0.1mm) to prevent equipment failure.

Unlike specialized modules such as the signal adaptation-focused GE DS200ADPBG1ABB (third-party device compatibility) or digital control-oriented GE DS200SDCCG1AEC (basic discrete control), GE DS200CTBAG1ADD is positioned as a “control-monitoring integration unit” for medium-scale turbines (100MW–300MW). It focuses on the coordinated management of turbine key auxiliary subsystems rather than single-function support—integrating control logic and monitoring functions to avoid the need for separate control and monitoring modules, thereby optimizing cost and cabinet space. By centralizing the control and status monitoring of 3–4 key auxiliary subsystems in a single Mark V-compatible slot, GE DS200CTBAG1ADD reduces the number of modules in the control cabinet by 40% and shortens the response time of abnormal state handling by 30%. For plant operators, GE DS200CTBAG1ADD acts as a “health guardian” for the Mark V system, ensuring the stable operation of key auxiliary subsystems while enabling timely detection and handling of potential faults to extend equipment service life.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200CTBAG1ADD |

| Manufacturer | General Electric (GE) |

| Product Type | Standard-Version Control & Status Monitoring Module (Mark V Speedtronic) |

| Core Function | Integrated control of key auxiliary subsystems; multi-dimensional status monitoring of turbine components; abnormal state early warning |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v4.5+) |

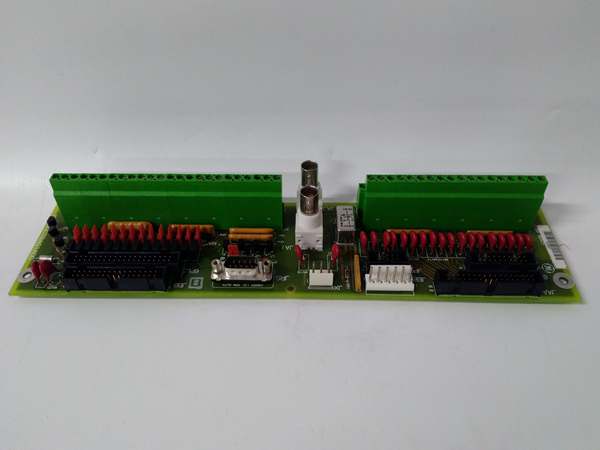

| Control Interfaces | – Analog Control Outputs: 8 channels (4–20mA, 0.1% accuracy) for regulating fuel flow, steam valve opening, and lubrication flow- Digital Control Outputs: 10 channels (24V DC, 2A per channel) for starting/stopping auxiliary pumps and activating solenoid valves- Control Logic Support: Ladder logic and function block programming (via Mark V HMI), supporting up to 64 control loops (e.g., PID pressure/temperature control) |

| Monitoring Interfaces | – Analog Monitoring Inputs: 12 channels (4–20mA/0–10V, 0.05% accuracy) for bearing temperature, rotor vibration, and pressure signals- Digital Status Inputs: 16 channels (24V DC, sinking/sourcing configurable) for equipment running status (e.g., pump on/off, valve open/closed)- Monitoring Frequency: 100Hz (real-time sampling of key signals such as vibration and temperature) |

| Early Warning Function | – Alert Thresholds: Configurable for each monitoring parameter (e.g., primary alert for bearing temperature 75°C, secondary alert for 85°C)- Alert Outputs: 4 channels (relay outputs, 250V AC @ 5A) for triggering audible/visual alarms or connecting to the plant’s emergency system- Data Logging: Automatically records abnormal state data (timestamp, parameter value, and fault code) for up to 1000 events |

| Communication Capabilities | – Mark V backplane bus (10Mbps, full-duplex) for data synchronization with the main controller- 1×RS-485 port (Modbus RTU) for connecting to local monitoring panels or data analysis systems- Support for remote status query and parameter adjustment via the Mark V network |

| Signal Processing | – Analog signal filtering: 2nd-order Butterworth filter (cutoff frequency 50Hz) to suppress interference- Digital signal debouncing: 1–100ms configurable filter to avoid false status detection- Temperature signal linearization: Built-in lookup table for PT100/Pt1000 thermocouples |

| Power Input | 24V DC (±15% tolerance); backplane-powered with isolated 12V DC for analog control circuits and 5V DC for digital monitoring circuits |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

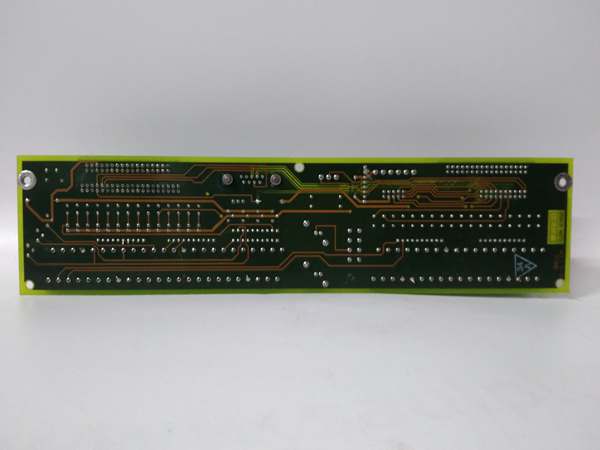

| Physical Dimensions | 175mm (L) × 120mm (W) × 42mm (D) (Mark V standard single-slot form factor) |

| Weight | ~520g (includes control circuits, monitoring chips, and filter components) |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61000-6-2 (industrial EMI immunity); IEC 60529 (IP rating) |

| Diagnostic Features | Control loop fault detection (e.g., PID output saturation); monitoring input signal loss alert; power supply voltage abnormal warning; communication error logging |

DS200CTBAG1ADD

Key Differentiators vs. Adaptation/Control Modules

To meet the integrated needs of control and monitoring for key auxiliary subsystems, GE DS200CTBAG1ADD differs from adaptation and basic control modules in functional positioning:

| Feature | GE DS200CTBAG1ADD (Control & Monitoring) | GE DS200ADPBG1ABB (Adaptation & Bridging) | GE DS200SDCCG1AEC (Digital Control) | Application Fit |

| Core Function | Integrated control + multi-dimensional monitoring + early warning | Signal conversion + protocol bridging | Basic discrete control + simple sequencing | Managing key auxiliary subsystems (fuel, steam, lubrication) |

| Control Capability | 8 analog control loops (PID) + 10 digital outputs | No control function (compatibility focus) | 12 digital outputs (no analog control) | Regulating continuous parameters (pressure, temperature, flow) |

| Monitoring Scope | 12 analog parameters (temperature, vibration) + 16 digital statuses | No monitoring function (signal adaptation only) | No dedicated monitoring (only control-related status) | Tracking component health and operating states |

| Early Warning | Configurable thresholds + event logging + alert outputs | No early warning (no parameter analysis) | Basic fault alert (only control failures) | Preventing equipment damage via abnormal state detection |

| Cost Position | Mid-range (integrated functions reduce module count) | Mid-low (single-function adaptation) | Mid-low (basic discrete control) | Cost-effective for auxiliary subsystem centralized management |

Main Features and Advantages

Integrated Control of Key Auxiliary Subsystems: GE DS200CTBAG1ADD provides 8 analog control channels and supports up to 64 PID control loops—enabling integrated control of multiple key auxiliary subsystems. For example, it can simultaneously regulate fuel pressure (via a 4–20mA signal to the fuel regulator valve), steam temperature (via adjusting the spray water valve), and bearing lubrication flow (via controlling the lubrication pump speed). A 150MW industrial steam turbine plant in Northern China used this module to control its fuel and steam systems, replacing 2 separate control modules and reducing cabinet wiring by 50% while improving the coordination between fuel supply and steam temperature control.

Multi-Dimensional Status Monitoring with High Accuracy: Equipped with 12 high-precision analog monitoring inputs (0.05% accuracy) and 16 digital status inputs, the module can track key operating parameters of turbine components in real time—including bearing temperature (via PT100 thermocouples), rotor vibration (via vibration sensors), and seal oil pressure (via pressure transmitters). The 100Hz sampling frequency ensures no missing of transient abnormal signals (e.g., sudden vibration spikes). A 180MW gas turbine plant in Southeast Asia used the module to monitor 6 bearing temperatures and 4 vibration points, achieving real-time temperature accuracy within ±0.1°C and vibration measurement accuracy within ±0.005mm—providing reliable data for equipment health assessment.

Configurable Early Warning to Prevent Faults: The module supports configurable alert thresholds for each monitoring parameter, with primary and secondary alert levels to realize hierarchical early warning. For example, when the bearing temperature reaches 75°C (primary alert), the module triggers a local light alarm; when it exceeds 85°C (secondary alert), it activates an audible alarm and sends a signal to the Mark V system to reduce turbine load. A 200MW combined-cycle plant in Southern Europe used this feature to detect a bearing temperature rise 15 minutes in advance, avoiding a turbine trip and reducing downtime losses by $120,000.

Strong Anti-Interference Capability for Stable Operation: The module’s 2nd-order Butterworth filter for analog signals and configurable debouncing for digital signals effectively suppress electromagnetic interference from industrial environments (e.g., interference from 6kV motor startups or high-voltage cable radiation). A 120MW regional utility turbine plant in Central Asia used the module in a high-interference workshop, and the monitoring data of key parameters (e.g., fuel pressure) showed a fluctuation range of only ±0.2%—far lower than the ±1% range of the previous non-filtered module, ensuring stable control and accurate monitoring.

Application Field

GE DS200CTBAG1ADD is widely used in medium-scale Mark V-based turbine systems requiring centralized management of key auxiliary subsystems, focusing on two core application scenarios: industrial turbine auxiliary subsystem control-monitoring integration and regional utility turbine component health management.

In industrial turbine auxiliary subsystem control-monitoring integration, GE DS200CTBAG1ADD ensures process stability. A 160MW industrial steam turbine plant in Eastern China (supporting a large chemical plant) deployed the module to manage its fuel supply and lubrication systems: 4 analog control channels regulated fuel flow and lubrication pressure, 8 analog monitoring channels tracked fuel pressure, bearing temperature, and lubrication flow, and 6 digital status channels monitored pump and valve operating states. The module’s integrated control logic ensured that lubrication pressure increased synchronously with fuel flow during load changes, avoiding bearing wear due to insufficient lubrication. Over 12 months, the plant recorded zero faults in the fuel and lubrication systems, improving turbine availability by 2%.

In regional utility turbine component health management, GE DS200CTBAG1ADD enables predictive maintenance. A 220MW gas turbine plant in Southwest Asia (supplying power to a provincial capital) used the module to monitor the health of key components: 6 bearing temperatures, 4 rotor vibration points, and 3 seal oil pressure points. The module’s early warning function detected abnormal vibration of the #3 bearing 20 minutes in advance, and the plant scheduled maintenance during a low-demand period—avoiding an unexpected turbine outage and ensuring continuous power supply to 500,000 residents.

Related Products

GE DS200ADPBG1ABB: Signal adaptation module that collaborates with GE DS200CTBAG1ADD—the latter receives adapted signals from third-party sensors (e.g., non-GE vibration sensors) for monitoring and control.

GE DS200SDCCG1AEC: Digital control module that complements the module for basic discrete control (e.g., controlling cooling fans) beyond the key auxiliary subsystems managed by GE DS200CTBAG1ADD.

GE DS200PCCAG1ABB: Power control module that provides stable 24V DC to GE DS200CTBAG1ADD’s control and monitoring circuits, ensuring high-precision signal processing.

GE PT100 Thermocouple: High-precision temperature sensor compatible with the module’s analog monitoring inputs, used for bearing temperature measurement.

GE Vibration Sensor (3500 Series): Vibration measurement sensor that works with the module to monitor rotor vibration amplitude and frequency.

GE IC660HHM501: Handheld diagnostic tool used to calibrate the module’s control loops, verify monitoring accuracy, and test early warning functions.

GE DS200TCEBG1ACE: Turbine protection module that receives abnormal state signals from GE DS200CTBAG1ADD (e.g., excessive vibration) to trigger emergency shutdowns.

GE Data Analysis Software (Asset Performance Management): Software that receives monitoring data from the module’s RS-485 port, enabling long-term trend analysis and predictive maintenance of turbine components.

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200CTBAG1ADD, confirm the Mark V system firmware is v4.5+ to support its integrated control and monitoring functions. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to avoid damaging the module’s high-precision analog circuits. Clarify the control requirements and monitoring parameters of key auxiliary subsystems—for example, configure PID parameters (proportional gain, integral time) for fuel pressure control via the Mark V HMI, and set alert thresholds for bearing temperature and vibration. Ensure that sensors (e.g., PT100 thermocouples, vibration sensors) are correctly calibrated to match the module’s input range (4–20mA/0–10V). Label control and monitoring channels clearly (e.g., “Analog Control Ch1: Fuel Regulator Valve”, “Analog Monitoring Ch1: #1 Bearing Temperature”) to simplify troubleshooting.

Maintenance recommendations: Perform weekly visual inspections of the module to check for loose control/monitoring terminals, corrosion on connectors, or illuminated fault/alert LEDs. Clean the module surface with a dry, lint-free cloth—avoid compressed air (which may damage internal filter components) or liquids. Monthly, verify control loop accuracy: adjust the setpoint of a control loop (e.g., fuel pressure from 1.0MPa to 1.2MPa) and check if the actual output follows the setpoint (allowable deviation ±0.5%). Calibrate monitoring inputs using a calibrated signal generator (e.g., input 12mA to simulate a bearing temperature of 60°C) and confirm the module’s displayed value matches the actual input (allowable deviation ±0.1%). Quarterly, review early warning event logs to identify recurring abnormal states (e.g., frequent primary alerts for #2 bearing temperature) and resolve root causes (e.g., cleaning the bearing lubrication passage). For high-humidity or dusty environments, conduct semi-annual inspections of terminal block insulation and sensor connections to ensure signal integrity.

DS200CTBAG1ADD

Product Guarantee

GE provides a 12-month standard warranty for GE DS200CTBAG1ADD, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61000-6-2 standards from the date of shipment. The warranty includes free replacement of faulty modules and 24/7 access to GE’s global technical support team—specializing in Mark V control-monitoring integration troubleshooting to resolve issues such as control loop instability, monitoring data inaccuracies, or early warning function malfunctions. For industrial power plants or regional utility projects, GE offers optional 18-month extended warranties and on-site commissioning support, where technicians assist with module configuration, PID parameter tuning, and alert threshold setting. GE’s OEM-certified repair services for GE DS200CTBAG1ADD include control circuit testing, monitoring chip calibration, and filter component replacement, with a 6-month post-repair warranty—ensuring long-term reliable operation of turbine key auxiliary subsystem control and monitoring systems.