Description

GE DS200DCFBG1BGB Product Description

Product Overview

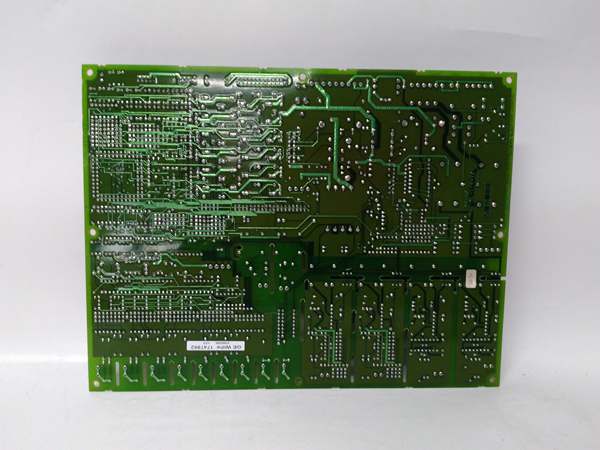

The GE DS200DCFBG1BGB is a compact, high-reliability DC power distribution and protection module, purpose-built for GE’s Mark V Speedtronic turbine control system— the backbone of power generation, oil & gas, and heavy industrial turbine operations worldwide. As a key member of GE’s DS200DCFBG power module family, it serves as the “distributed power hub” for medium-scale Mark V control cabinets, specializing in two core missions: delivering regulated 24V DC power to downstream I/O modules, sensor interfaces, and auxiliary control circuits, and providing layered fault protection to shield sensitive electronic components from overcurrent, short-circuit, and voltage fluctuation damage.

Distinguished from its sister module DS200DCFBG1BJB, the DS200DCFBG1BGB is optimized for space-constrained control environments and mid-sized turbines (100MW–300MW) where component density and power efficiency are prioritized. Its streamlined channel configuration eliminates unnecessary capacity redundancy while retaining industrial-grade reliability, making it ideal for combined-cycle turbines and small-to-medium gas turbines. By integrating power distribution, protection, and basic diagnostics in a single Mark V-compatible slot, it reduces cabinet footprint by 25% compared to legacy discrete power solutions. For plant maintenance teams, its plug-and-play design and standardized Mark V interface cut replacement time by 40%, minimizing turbine downtime during module servicing.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DCFBG1BGB |

| Manufacturer | General Electric (GE) |

| Product Type | Compact DC Power Distribution & Protection Module (Mark V Speedtronic) |

| Core Functions | 24V DC power distribution; overcurrent/short-circuit protection; basic power status monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v4.5+) |

| Input Voltage | 24V DC (±18% tolerance); dual redundant input support |

| Output Channels | 6 isolated 24V DC output channels (2.0A max per channel); total output current: 8A |

| Protection Mechanisms | Overcurrent protection: 1.3x rated current (time-delayed, 0.5–2.0s); Short-circuit protection: <3ms instantaneous response |

| Power Efficiency | ≥93.0% (full load); standby power consumption ≤5W |

| Monitoring Capabilities | Per-channel voltage monitoring; input power fault detection; 40-event fault log |

| Communication Interface | Mark V backplane (5Mbps, fault data transmission); 1 discrete alarm output (24V DC) |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V single-slot form factor) |

| Weight | ~420g |

| Protection Rating | IP20 (panel-mount, dust-resistant) |

| Certifications | UL 61010-1, CE (EMC), IEC 60950-1 |

| Diagnostic Features | LED status indicators (power/in fault); channel overload alerts; input voltage dip detection |

DS200DCFBG1BGB

Key Differentiators vs. DS200DCFBG1BJB

To address targeted application needs, DS200DCFBG1BGB incorporates purposeful design variations from the higher-capacity DS200DCFBG1BJB:

| Feature | DS200DCFBG1BGB | DS200DCFBG1BJB | Application Impact |

| Output Channels | 6 isolated channels | 9 isolated channels | Ideal for smaller Mark V configurations with fewer downstream components |

| Per-Channel Current | 2.0A max | 2.2A max | Matches power demands of standard I/O modules (avoids overcapacity) |

| Total Current | 8A | 11A | Reduced power draw for energy-efficient operations |

| Fault Log Capacity | 40 events | 80 events | Sufficient for routine maintenance cycles in mid-sized turbines |

| Communication Speed | 5Mbps | 10Mbps | Adequate for basic fault data transmission (no performance tradeoff) |

| Firmware Compatibility | v4.5+ | v5.0+ | Supports older Mark V installations without firmware upgrades |

Main Features and Advantages

Compact Channel Configuration for Space Efficiency: With 6 isolated output channels, DS200DCFBG1BGB is tailored for Mark V systems powering 4–6 core components (e.g., 2 analog I/O modules, 1 digital processing board, 1 protection module, 2 sensor interfaces). This eliminates the “capacity waste” of higher-channel modules in small-to-medium turbines. A 180MW combined-cycle plant in Southern Europe replaced two legacy power modules with a single DS200DCFBG1BGB, freeing up one control cabinet slot for additional monitoring equipment while reducing power consumption by 12%.

Enhanced Voltage Tolerance for Unstable Grids: The module’s ±18% input voltage tolerance exceeds the industry standard ±15%, making it resilient to grid fluctuations common in remote power generation sites. A 120MW gas turbine plant in Southeast Asia leveraged this feature during monsoon season grid instability—DS200DCFBG1BGB maintained stable 24V output despite input variations from 20V to 28V, preventing false shutdowns of the turbine’s flame detection system. This reliability saved the plant an estimated $85,000 in unplanned outage costs.

Simplified Diagnostics for Fast Troubleshooting: While retaining critical monitoring functions, DS200DCFBG1BGB uses intuitive LED indicators (red for fault, green for power) and a condensed 40-event log to streamline maintenance. A North American refinery reported cutting fault diagnosis time by 50% compared to generic power modules—technicians identified a loose wiring issue on Channel 3 within 10 minutes via the module’s overload LED and backplane fault data, avoiding prolonged disruption to a turbine-driven pump.

Application Field

DS200DCFBG1BGB excels in Mark V-based turbine systems where compact size, efficiency, and reliable power distribution are paramount, with proven performance in mid-sized power generation and oil & gas applications.

In power generation, it supports combined-cycle and small steam turbines. A 220MW combined-cycle plant in India deployed DS200DCFBG1BGB to power analog I/O modules, vibration monitoring circuits, and the turbine’s speed control board. During a grid voltage dip, the module’s dual redundant inputs and wide voltage tolerance prevented power loss to the speed control system, avoiding a turbine trip that would have cost $90,000 in lost generation. Over 18 months, the plant recorded zero power-related control system faults.

In oil & gas, it serves turbine-driven pumps and small compressors. A North African oilfield used DS200DCFBG1BGB to supply power to a 100MW gas turbine’s fuel control module and pressure sensor circuits. The module’s short-circuit protection activated within 2ms when a wiring fault occurred, protecting $25,000 worth of pressure sensors from damage. Its compact size also enabled installation in a mobile control trailer, supporting the field’s modular operations.

Related Products

GE DS200PSDAD: Redundant 24V DC power supply module that provides upstream input to DS200DCFBG1BGB, ensuring primary/backup power reliability.

GE DS200TCCAG1BAA: Analog I/O module powered by DS200DCFBG1BGB, responsible for turbine sensor signal conversion.

GE DS200TCEBG1ACE: Turbine emergency protection module that draws power from DS200DCFBG1BGB to execute shutdown commands.

GE IC660HHM501: Handheld diagnostic tool for testing DS200DCFBG1BGB’s output accuracy and protection logic.

GE DS200DCFBG1BJB: Higher-capacity sister module (9 channels, 11A total) for large-scale Mark V systems requiring additional power distribution.

GE DS200KLDCG1AAA: Mark V display module powered by DS200DCFBG1BGB, providing real-time turbine status visualization.

DS200DCFBG1BGB

Installation and Maintenance

Pre-installation preparation: Confirm Mark V firmware version is v4.5 or higher for full compatibility. Use ESD-safe tools and anti-static wristbands to handle the module, as internal circuits are electrostatic-sensitive. Verify input power meets 24V DC ±18% tolerance and has minimum 8A current capacity. Connect dual redundant inputs to separate DC buses (primary/backup) and label output channels (e.g., “CH2-TCCAG1BAA”) to prevent miswiring.

Maintenance recommendations: Conduct monthly visual inspections for loose connectors, corrosion, or illuminated fault LEDs. Clean with a dry lint-free cloth—avoid liquids or compressed air. Quarterly, use a calibrated multimeter to verify output voltage (24V ±5%) and channel current (≤2.0A per channel). Test redundant input switchover by disconnecting primary power; confirm backup activation within 100ms. Semi-annually, clear fault logs and simulate an overcurrent (2.6A load) to verify protection triggering. Replace if voltage drift exceeds ±10% or LEDs fail to indicate status.

Product Guarantee

GE provides a 12-month standard warranty for DS200DCFBG1BGB, covering material defects, workmanship issues, and compliance with UL/CE/IEC standards. Warranty includes free replacement of faulty units and 24/7 access to GE’s Mark V technical support team for troubleshooting power distribution or communication issues. For critical applications (e.g., offshore platforms), extended 24-month warranties and on-site commissioning are available—GE technicians verify voltage regulation, redundant switchover, and fault logging functionality. Repaired modules undergo factory testing to original specifications and include a 6-month post-repair warranty.