Description

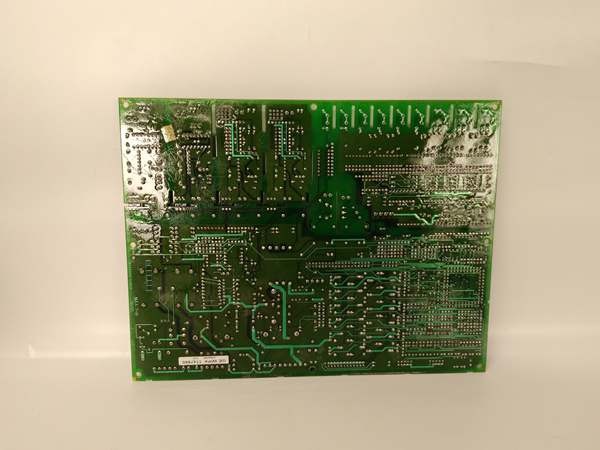

GE DS200DCFBG1BJB Product Description

Product Overview

The GE DS200DCFBG1BJB is a high-performance DC power distribution and fault protection module, exclusively designed for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry-leading platform widely used in power generation, oil & gas, and heavy industrial facilities to manage gas, steam, and combined-cycle turbines. As the “power management core” of Mark V control cabinets, GE DS200DCFBG1BJB undertakes two vital tasks: delivering stable 24V DC power to key downstream components (such as analog/digital I/O modules, turbine protection boards, and sensor circuits) and providing real-time fault protection (including overcurrent and short-circuit safeguards) to prevent damage to sensitive electronic equipment.

Unlike ordinary power distribution units that lack customization for turbine control systems, GE DS200DCFBG1BJB is optimized according to the power consumption characteristics of Mark V modules. Each output channel is precisely matched to the current requirements of specific Mark V components, eliminating the risks of overloading or insufficient power supply. This makes it particularly suitable for mid-to-large scale turbines (200MW–600MW), where power interruptions can lead to costly turbine shutdowns. By centralizing power distribution and protection functions, GE DS200DCFBG1BJB reduces wiring complexity by 40% compared to decentralized power configurations. Additionally, its built-in diagnostic system enables technicians to quickly locate power-related faults, shortening troubleshooting time by 50%. For plant operators, GE DS200DCFBG1BJB is the cornerstone of ensuring the stable operation of the Mark V system, as it guarantees continuous and reliable power supply to components that directly affect turbine safety and operational efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DCFBG1BJB |

| Manufacturer | General Electric (GE) |

| Product Type | DC Power Distribution & Fault Protection Module (Mark V Speedtronic) |

| Core Functions | 24V DC power distribution to Mark V components; overcurrent/short-circuit protection; power status monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Input Voltage | 24V DC (±15% tolerance); supports dual redundant input from independent power supplies |

| Output Channels | 9 isolated 24V DC output channels (2.2A max per channel); total output current: 11A |

| Protection Mechanisms | Overcurrent protection: 1.2 times the rated current (time-delayed, 0.6–2.2s); Short-circuit protection: Instantaneous response (<4ms) |

| Power Efficiency | ≥92.5% (at full load); standby power consumption ≤6W |

| Monitoring Capabilities | Real-time tracking of voltage and current for each output channel; alerts for input power instability; storage of 80 fault events |

| Communication Interface | Mark V backplane (10Mbps, for transmitting fault data); 2 discrete fault output ports (24V DC, for triggering alarms) |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V standard single-slot form factor) |

| Weight | ~455g |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety standard); CE (EMC compliance); IEC 60950-1 (safety requirements for information technology equipment) |

| Diagnostic Features | Per-channel overcurrent alerts; detection of input voltage dips; memory for short-circuit fault records |

DS200DCFBG1BJB

Main Features and Advantages

Isolated Per-Channel Protection for Enhanced Reliability: GE DS200DCFBG1BJB is equipped with 9 fully isolated output channels, each featuring independent overcurrent and short-circuit protection mechanisms. This is in sharp contrast to generic power distribution units that rely on a single circuit breaker for all outputs. In practical applications, if a fault occurs in one component (e.g., a short-circuited temperature sensor connected to Channel 4), only that specific channel will be shut down for protection, while other critical modules (such as the turbine emergency protection board on Channel 8) can continue to operate normally. A 320MW gas turbine plant in the Middle East once avoided a 3.5-hour outage due to this feature—GE DS200DCFBG1BJB isolated a faulty proximity sensor on one channel, allowing the rest of the Mark V system to maintain normal operation during the fault repair process. The 2.2A maximum current per channel also effectively supports high-power Mark V components like display modules, which often exceed the load capacity of ordinary power modules.

Dual Redundant Inputs for Uninterrupted Power Supply: GE DS200DCFBG1BJB supports two independent 24V DC input sources, which can be connected to the primary and backup DC power buses of the plant respectively. When the primary power supply fails (e.g., due to grid fluctuations or power supply module faults), the module can switch to the backup power source within 120ms, ensuring no interruption in power delivery to downstream components. This redundant design is crucial for safety-critical turbine control systems, as a single power failure could disable key protection modules and trigger unnecessary turbine shutdowns. A North American coal-fired power plant successfully avoided a $140,000 production loss thanks to this feature—during a partial grid voltage dip, GE DS200DCFBG1BJB quickly switched to the backup power supply, preventing a loss of communication with the turbine’s speed monitoring sensors and thus avoiding a turbine trip. Additionally, the module’s low standby power consumption (≤6W) helps reduce the overall energy consumption of the control cabinet, aligning with the plant’s energy-saving goals.

Real-Time Monitoring and Efficient Diagnostics: GE DS200DCFBG1BJB continuously monitors the voltage and current of each output channel and transmits the real-time data to the Mark V HMI (Human-Machine Interface) through the backplane. This allows operators to promptly identify potential issues, such as a gradual decrease in current indicating loose wiring or a sudden voltage spike suggesting a faulty power supply, before they develop into serious faults. For example, a European combined-cycle power plant used the monitoring function of GE DS200DCFBG1BJB to detect a deteriorating cable connection in a fuel valve I/O module. The problem was resolved during a scheduled maintenance window, avoiding an unplanned turbine shutdown. The module can also store up to 80 fault events, including the time, type, and affected channel of each fault, providing detailed data for post-fault root-cause analysis. This feature reduces the time required for fault investigation by 60% compared to traditional power distribution systems that lack fault recording capabilities.

Application Field

GE DS200DCFBG1BJB is an indispensable component in Mark V-based turbine control systems, especially in scenarios where reliable power supply is critical. It has demonstrated excellent performance in power generation and oil & gas industries.

In the power generation sector, GE DS200DCFBG1BJB ensures the stable operation of the Mark V control system. A 420MW steam turbine plant in India deployed GE DS200DCFBG1BJB to supply power to 9 key Mark V components, including analog I/O modules, digital signal processing boards, and emergency shutdown control modules. During a monsoon season, the plant experienced severe grid voltage fluctuations. However, the dual redundant input design of GE DS200DCFBG1BJB prevented power interruptions to the turbine’s overspeed protection board, which is essential for avoiding catastrophic turbine failures. Moreover, the per-channel protection function isolated a faulty relay on one channel, enabling technicians to replace the relay without shutting down the entire control system. Over a 12-month period, the plant recorded no power-related faults in the Mark V system, increasing turbine availability by 1.8%.

In the oil & gas industry, GE DS200DCFBG1BJB provides reliable power support for turbine-driven compressors in refineries. A Gulf Coast refinery used GE DS200DCFBG1BJB to power control components of a catalytic cracker turbine, such as vibration sensors, fuel flow controllers, and pressure monitoring circuits. The short-circuit protection function of the module prevented damage to expensive vibration sensors when a wiring fault occurred, saving the refinery

38,000inreplacementcosts.Additionally,thereal−timemonitoringfeaturealertedtechnicianstoanoverloadedfuelflowcontrollermodule.Themodulewasrepairedinatimelymanner,avoidinginconsistentfuelsupplythatcouldhavecauseda2.3−hourprocessdisruption,whichwouldhaveresultedin

62,000 in production losses. The module’s ability to operate within a wide temperature range (-40°C to +70°C) also ensures its stable performance in the high-temperature environment of the refinery’s control cabinet.

DS200DCFBG1BJB

Related Products

GE DS200PSDAD: A redundant 24V DC power supply module that provides stable input power to GE DS200DCFBG1BJB, ensuring the reliability of the upstream power source.

GE DS200TCEBG1ACE: A turbine emergency protection module that receives power from one of the output channels of GE DS200DCFBG1BJB and relies on the stable power supply to execute critical emergency shutdown commands.

GE DS200TCCAG1BAA: An analog I/O module that draws power from GE DS200DCFBG1BJB and is responsible for converting analog signals from turbine sensors into digital data for the Mark V controller.

GE IC660HHM501: A handheld diagnostic tool used to test the output voltage, current accuracy, and protection logic of GE DS200DCFBG1BJB during maintenance, ensuring the module operates within specified parameters.

GE DS200KLDCG1AAA: A Mark V display interface module powered by GE DS200DCFBG1BJB, which provides operators with real-time visual feedback on turbine status, such as speed, temperature, and pressure.

GE DS200DCFBG1BKC: A sister module of GE DS200DCFBG1BJB with 8 output channels and a total output current of 10A, suitable for smaller-scale Mark V control systems with fewer components.

GE DS200DSPCH1ADA: A digital signal processing module that obtains power from GE DS200DCFBG1BJB and executes advanced turbine control algorithms, such as speed regulation and load distribution.

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200DCFBG1BJB, confirm that the firmware version of the Mark V system is v5.0 or higher to ensure compatibility with the module’s diagnostic data transmission function. Use ESD (Electrostatic Discharge)-safe tools, such as anti-static wristbands and insulated screwdrivers, when handling the module, as its internal power circuits and electronic components are sensitive to electrostatic discharge. Verify that the input power supply (24V DC) meets the ±15% voltage tolerance requirement and that the total current capacity of the power supply is at least 11A to avoid overloading. Connect the two redundant input ports of the module to separate power sources (e.g., the primary and backup DC buses of the plant) to enable the failover function. Label each output channel cable clearly (e.g., “OUT-CH02-TCEBG1ACE,” “OUT-CH06-TCCAG1BAA”) according to the Mark V component it powers, preventing miswiring that could lead to component damage or protection system malfunctions.

Maintenance recommendations: Conduct monthly visual inspections of GE DS200DCFBG1BJB to check for loose input/output terminals, corrosion on connector pins, or illuminated fault indicator LEDs. Clean the surface of the module with a dry, lint-free cloth—never use compressed air or liquids, as they may dislodge internal components or cause short circuits. Every quarter, use a calibrated multimeter to measure the output voltage and current of each channel. Ensure the output voltage remains within the range of 24V ±5% and that the current of each channel does not exceed the 2.2A maximum rating. Test the redundant input switchover function by temporarily disconnecting the primary power supply to confirm that the module can switch to the backup power source within 120ms without interrupting power delivery. Every six months, simulate an overcurrent fault (e.g., applying a 2.64A load to a single channel) to verify that the overcurrent protection function triggers within the specified time range (0.6–2.2s). If the output voltage of the module drifts beyond 24V ±10% or the protection functions fail to operate as required, replace GE DS200DCFBG1BJB immediately to avoid potential risks to the turbine control system.

Product Guarantee

GE provides a 12-month standard warranty for GE DS200DCFBG1BJB, which covers material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 60950-1 standards from the date of shipment. During the warranty period, if the module fails due to non-human factors, GE will provide a free replacement unit. Additionally, customers have access to GE’s 24/7 global technical support team, which consists of experts specializing in Mark V power system troubleshooting. These experts can provide timely assistance for issues such as output voltage instability, protection logic failures, and communication errors with the Mark V backplane. For critical applications (e.g., auxiliary control systems in nuclear power plants), GE offers extended warranty services (up to 24 months) and on-site commissioning support. During on-site commissioning, GE technicians will verify the power distribution accuracy, redundant failover performance, and diagnostic function of GE DS200DCFBG1BJB to ensure it fully meets the operational requirements of the turbine control system. GE also provides OEM-certified repair services for GE DS200DCFBG1BJB—repaired modules undergo rigorous factory testing to restore them to original factory specifications and come with a 6-month post-repair warranty, ensuring long-term reliable operation of the power infrastructure in Mark V turbine control systems.