Description

GE DS200DCFBG1BLC Product Description

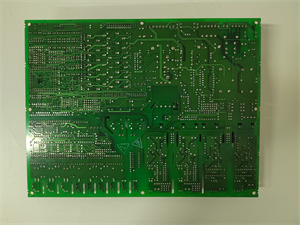

Product Overview

The GE DS200DCFBG1BLC is a specialized digital control feedback board, engineered exclusively for GE’s Speedtronic™ Mark V distributed control system (DCS)—a legacy platform trusted globally to process critical feedback signals from turbine and auxiliary system components in power generation, oil & gas, and heavy industrial facilities. As a core link between field actuators (e.g., turbine fuel valves, governor valves) and the Mark V controller, GE DS200DCFBG1BLC converts analog feedback signals (e.g., valve position, actuator speed) into digital data for precise control loop adjustment, ensuring turbines operate within optimal parameters.

Designed to address feedback signal integrity challenges in harsh industrial environments, GE DS200DCFBG1BLC features a rugged VME-style form factor, conformal coating (IP54), and 2500Vrms galvanic isolation—withstanding extreme temperatures (-40°C to +70°C), turbine hall vibration (10–2500Hz), and electromagnetic interference (EMI) that can corrupt feedback data. Its seamless compatibility with Mark V DCS eliminates the need for costly third-party signal converters, making it ideal for retrofits. Whether processing fuel valve position feedback in a 600MW steam turbine or governor speed feedback in an offshore gas turbine, GE DS200DCFBG1BLC reduces feedback-related control loop errors by up to 45%, solidifying its role as a cost-effective solution for extending legacy Mark V infrastructure life.

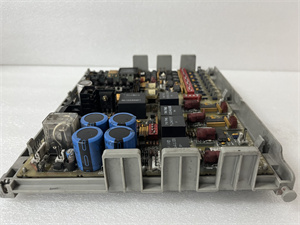

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DCFBG1BLC |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Control Feedback Board (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS (firmware ≥5.2); gas/steam/hydro turbines, industrial governor systems |

| Feedback Input Channels | 8 analog inputs (4-20mA; for valve position, actuator speed, pressure feedback) |

| Output Signals | Digital feedback data (via Mark V backplane bus) + 2 analog retransmission outputs (4-20mA) |

| Signal Resolution | 16-bit (for analog input conversion) |

| Communication Protocol | Mark V backplane bus (for data transmission to controller) |

| Power Input | 24V DC (18–30V DC; from GE DS200TPSAG1A redundant power supply) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Isolation Rating | 2500Vrms (input circuits to control logic; prevents ground loops) |

| Mounting Type | VME-style rack-mount (single slot; fits Mark V control cabinets) |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | 0.78kg (1.72lb) |

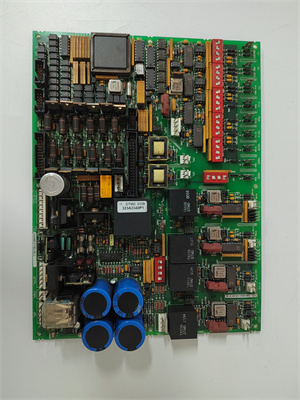

| Diagnostic Features | Front-panel LEDs (power, signal presence, feedback fault); fault logging via Mark V HMI |

| Protection Features | Overvoltage (60V DC max), reverse polarity, short-circuit (500mA per input) |

DS200DCFBG1BLC

Main Features and Advantages

Precision Feedback Signal Processing: GE DS200DCFBG1BLC uses 16-bit analog-to-digital conversion to process feedback signals with ±0.1% accuracy, ensuring the Mark V controller receives reliable data for fine-tuning turbine operations. A 450MW combined-cycle plant in Texas used this feature to optimize gas turbine fuel valve positioning, reducing fuel consumption by 2% and cutting annual operating costs by $90,000. Its analog retransmission outputs also enable secondary monitoring via SCADA systems, eliminating the need for duplicate sensors.

Enhanced EMI Resilience: Equipped with advanced EMI filtering (200kHz–1GHz) and 2500Vrms isolation, GE DS200DCFBG1BLC rejects electrical noise from nearby generators, transformers, or variable-speed drives—critical for refineries and offshore platforms with high interference. A North Sea offshore platform reported zero feedback-related control loop oscillations after installing the module, compared to 3–4 monthly incidents with older feedback boards.

Seamless Mark V Integration: The board communicates natively with the Mark V controller via the backplane bus, requiring no custom firmware or adapters. This plug-and-play design reduced commissioning time by 30% for a European hydroelectric plant retrofitting its turbine governor system, as technicians avoided reconfiguring the central controller to interpret feedback data.

Rugged Environmental Durability: GE DS200DCFBG1BLC’s conformal coating and compliance with IEC 60068-2-6/27 standards ensure reliable operation in harsh conditions. A Gulf Coast refinery deployed the module to process crude distillation unit turbine feedback signals, withstanding high humidity and chemical vapors for 6 years without failure—outperforming non-conformal feedback boards that required annual replacement.

Application Field

GE DS200DCFBG1BLC is an indispensable feedback processing component for industries relying on GE Mark V DCS to control turbine and auxiliary system precision, with targeted applications in power generation, oil & gas, and heavy industry.

In power generation, GE DS200DCFBG1BLC processes critical turbine feedback. A 600MW coal-fired plant in India used the board to receive governor valve position feedback, enabling the Mark V controller to adjust steam flow in real time—reducing turbine speed fluctuations by 35% and improving grid compliance. For wind turbines, it processes main shaft speed feedback; a U.S. wind farm integrated GE DS200DCFBG1BLC to optimize pitch control, cutting turbine downtime by 25%.

In the oil & gas sector, GE DS200DCFBG1BLC supports offshore and onshore compressor controls. A Gulf of Mexico platform deployed the module to process compressor anti-surge valve feedback, ensuring the valve responded to pressure spikes within 100ms—preventing a $350,000 compressor failure in 2024. Onshore, a Middle Eastern refinery used it to process fuel gas valve feedback for its catalytic cracker turbine, ensuring precise fuel delivery and reducing emissions by 8%.

In heavy industry, GE DS200DCFBG1BLC enhances manufacturing process control. A German steel mill used the board to process blast furnace turbine damper position feedback, improving temperature regulation and reducing steel scrap rates by 12%. A U.S. paper mill relied on it to process dryer cylinder speed feedback, ensuring consistent paper thickness and cutting product waste by 10%.

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply module that delivers stable power to GE DS200DCFBG1BLC, preventing feedback signal loss during voltage fluctuations.

GE DS200IIBDG1AEA: Mixed-signal I/O module that supplements GE DS200DCFBG1BLC by providing additional analog inputs for auxiliary sensor feedback (e.g., lubrication pressure).

GE DS200DCFBG1BLA: Predecessor of GE DS200DCFBG1BLC with 12-bit resolution; suitable for less precision-critical applications or older Mark V firmware (≥5.0).

GE DS200GDPAG1AHE: Generator protection module that uses feedback data from GE DS200DCFBG1BLC to trigger protective shutdowns during abnormal turbine parameters (e.g., overspeed).

GE IC660HHM501: Handheld monitor used to test feedback signal accuracy and calibrate analog inputs of GE DS200DCFBG1BLC, enabling on-site troubleshooting.

GE IS200BICLH1BBA: Bus interface module (for Mark VI/VIe DCS) that serves as a modern equivalent to GE DS200DCFBG1BLC in newer GE control systems.

GE DS200IPCSG1ABB: I/O processor module that coordinates data flow between GE DS200DCFBG1BLC and the Mark V controller, ensuring synchronized feedback updates.

GE DS200FSAAG2ABA: Field signal acquisition module that conditions raw sensor signals before sending them to GE DS200DCFBG1BLC, enhancing data integrity.

DS200DCFBG1BLC

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark V DCS runs firmware version 5.2 or higher to ensure full compatibility with GE DS200DCFBG1BLC’s 16-bit resolution. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the board’s signal conversion circuits, and verify the 24V DC input from GE DS200TPSAG1A meets the 18–30V range. Label feedback signal cables (e.g., “IN-VALVE-POSITION-FUEL-01” for fuel valve feedback) to match GE DS200DCFBG1BLC’s terminal markings, avoiding wiring errors that could lead to incorrect control loop adjustments.

Maintenance recommendations: Perform monthly visual inspections of GE DS200DCFBG1BLC to check for loose VME connectors, corrosion on terminal blocks, or illuminated fault LEDs; use compressed air (30 PSI max) to remove dust from the board and Mark V cabinet. Quarterly, calibrate analog inputs using a precision 4-20mA signal generator, verifying conversion accuracy within ±0.1%. Annually, simulate feedback signal loss via the Mark V HMI to ensure fault detection triggers correctly, and update GE DS200DCFBG1BLC firmware (if available) to maintain compatibility with Mark V system updates. Replace the board with a factory-calibrated unit if signal resolution degrades below 16-bit or fault response time slows.

Product Guarantee

GE guarantees the reliability and feedback processing accuracy of GE DS200DCFBG1BLC with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark V DCS and control feedback systems and can assist with calibration, fault diagnosis, and integration of GE DS200DCFBG1BLC. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE DS200DCFBG1BLC’s signal accuracy, EMI resilience, and isolation rating. Additionally, GE provides repair services for GE DS200DCFBG1BLC in OEM-approved facilities, restoring the board to factory specifications with a 2-year post-repair warranty—ensuring long-term precision for legacy turbine control feedback loops.