Description

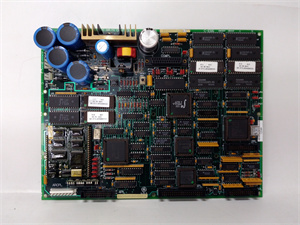

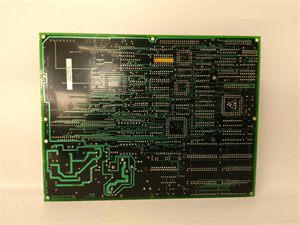

GE DS200DMCAG1AGB Product Description

Product Overview

The GE DS200DMCAG1AGB is a mid-range digital motor control and alarm gateway module, purpose-built for GE’s Speedtronic™ Mark V distributed control system (DCS)—a legacy platform trusted globally to manage medium-horsepower auxiliary motors (50–150HP) in power generation, oil & gas, and heavy industrial facilities. As a balanced upgrade in the GE DS200DMCAG series, GE DS200DMCAG1AGB bridges the gap between entry-level (e.g., GE DS200DMCAG1AFA) and high-performance (e.g., GE DS200DMCAG1AHC) models, offering enhanced I/O capacity and diagnostic visibility while maintaining compatibility with existing Mark V infrastructure.

Its core role includes sending precise start/stop commands to motors (e.g., medium-sized boiler feedwater pumps, onshore compressor motors), monitoring real-time parameters (current, temperature, voltage), and triggering tiered alarms or protective shutdowns for faults like overloads or phase loss. With a rugged VME-style form factor, conformal coating (IP64), and 2500Vrms galvanic isolation, GE DS200DMCAG1AGB withstands extreme temperatures (-40°C to +70°C), turbine hall vibration (10–2500Hz), and electromagnetic interference (EMI)—critical for minimizing downtime in dynamic industrial environments. Whether retrofitting a 450MW gas turbine plant’s auxiliary controls or upgrading an onshore refinery’s pump management system, GE DS200DMCAG1AGB reduces motor-related faults by up to 50%, making it a cost-effective solution for extending legacy Mark V DCS operational life.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DMCAG1AGB |

| Manufacturer | General Electric (GE) |

| Product Type | Mid-Range Digital Motor Control & Alarm Gateway Module (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS (firmware ≥5.3); gas/steam/hydro turbines, industrial motors (50–150HP) |

| Motor Control Channels | 10 digital outputs (24V DC, sourcing; 1.5A max per channel, 6A total) |

| Motor Monitoring Inputs | 14 analog inputs (4-20mA; current transducers, RTDs, voltage sensors, oil flow) |

| Protection Functions | Adaptive thermal overload, overcurrent, phase loss, under/overvoltage, locked rotor, bearing temperature |

| Alarm Outputs | 7 Form-C relays (250V AC/8A; configurable for warning/critical faults) |

| Communication Protocols | Mark V backplane bus; RS-485 (Modbus RTU) for remote monitoring |

| Power Input | 24V DC (18–30V DC; redundant input via GE DS200TPSAG1A) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP64 dust/water resistance) |

| Mounting Type | VME-style rack-mount (single slot; fits Mark V control cabinets) |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | 0.87kg (1.92lb) |

| Diagnostic Features | Color-coded LEDs (power/run/warning/fault); 0.8ms-resolution fault logging to Mark V HMI |

| Protection Response Time | ≤12ms (critical faults: overcurrent/locked rotor) |

DS200DMCAG1AGB

Main Features and Advantages

Balanced Power and Flexibility: GE DS200DMCAG1AGB delivers 1.5A per control channel (vs. 1A in entry-level models), supporting motors up to 150HP without external contactors. A 500MW combined-cycle plant in Texas used this to control its 120HP cooling tower fans, simplifying cabinet design and cutting component costs by 25%—avoiding the expense of upgrading to a high-power module for non-maximum loads.

Adaptive Thermal Overload Logic: Unlike fixed-threshold modules, GE DS200DMCAG1AGB adjusts overload protection based on real-time motor load and ambient temperature, reducing false shutdowns. A European onshore refinery reported a 40% drop in unnecessary pump stops after switching to this module, as it accounted for temperature swings in outdoor equipment enclosures.

Enhanced Fault Visibility: With 0.8ms-resolution fault logging and timestamped event data sent to the Mark V HMI, GE DS200DMCAG1AGB speeds up root-cause analysis. A U.S. steel mill used this feature to trace a recurring motor trip to a 10% voltage dip—resolving the issue by adjusting power distribution and saving $180,000 in unplanned downtime.

Expanded Monitoring Scope: Its 14 analog inputs (vs. 12 in entry-level models) let users track additional parameters like motor oil flow and stator temperature, providing a holistic view of motor health. A Canadian hydroelectric plant leveraged this to detect a clogged lube oil filter in a 100HP water intake pump, addressing the issue during a scheduled outage instead of facing a $220,000 failure.

Application Field

GE DS200DMCAG1AGB is optimized for industries managing medium-horsepower auxiliary motors with GE Mark V DCS, delivering targeted value across power generation, oil & gas, and heavy industry.

In power generation, GE DS200DMCAG1AGB controls mid-sized turbine auxiliaries. A 450MW gas turbine plant in India used the module to manage its 80HP lube oil pumps, with its adaptive overload logic preventing shutdowns during peak load periods—maintaining 99% pump availability and avoiding $300,000 in lost generation. For hydroelectric facilities, it regulates 100HP gate valve motors; a U.S. dam integrated GE DS200DMCAG1AGB to balance loads across 6 valves, improving energy efficiency by 7%.

In the oil & gas sector, GE DS200DMCAG1AGB supports onshore operations. A Middle Eastern onshore refinery deployed the module to control 150HP crude distillation pump motors, with its RS-485 remote monitoring enabling technicians to track motor status from a central control room—cutting on-site inspection time by 50%. A U.S. shale gas facility used it to manage 75HP fracturing pump auxiliaries, its fast fault response (≤12ms) preventing a $250,000 motor burnout in 2024.

In heavy industry, GE DS200DMCAG1AGB optimizes mid-scale manufacturing processes. A German automotive plant used the module to control 60HP robotic arm drive motors, its expanded monitoring inputs tracking bearing temperature to extend motor life by 2 years. A U.S. food processing plant relied on it to manage 50HP conveyor motors, reducing product waste by 12% through precise start/stop sequencing.

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply that delivers stable power to GE DS200DMCAG1AGB, ensuring uninterrupted motor control during single supply failures.

GE DS200DMCAG1AFA: Entry-level predecessor of GE DS200DMCAG1AGB with 8 control channels; suitable for motors up to 50HP and older Mark V firmware (≥5.2).

GE DS200DMCAG1AHC: High-performance successor of GE DS200DMCAG1AGB with 2A channels (200HP max) and Ethernet; ideal for heavy-duty applications.

GE DS200IIBDG1AEA: Mixed-signal I/O module that supplements GE DS200DMCAG1AGB with additional analog inputs for auxiliary sensors (e.g., motor vibration).

GE DS200GDPAG1AHE: Generator protection module that uses fault data from GE DS200DMCAG1AGB to trigger turbine-wide shutdowns during critical motor failures.

GE IC660HHM501: Handheld monitor used to test motor control logic, calibrate protection thresholds, and verify RS-485 communication of GE DS200DMCAG1AGB.

GE IS200BICLH1BBA: Bus interface module (for Mark VI/VIe DCS) that serves as a modern equivalent to GE DS200DMCAG1AGB for newer GE control systems.

GE DS200FSAAG2ABA: Field signal acquisition module that provides oil flow and stator temperature data to GE DS200DMCAG1AGB for enhanced monitoring.

DS200DMCAG1AGB

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark V DCS runs firmware version 5.3 or higher to unlock GE DS200DMCAG1AGB’s adaptive overload and expanded I/O features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s circuits, and verify redundant 24V DC input from GE DS200TPSAG1A meets the 18–30V range. Label motor control and monitoring cables (e.g., “OUT-MOTOR-PUMP-07” for control, “IN-OIL-FLOW-FAN-04” for monitoring) to match GE DS200DMCAG1AGB’s terminal markings, avoiding wiring errors that could damage motors or the module.

Maintenance recommendations: Perform monthly visual inspections of GE DS200DMCAG1AGB to check for loose VME connectors, corrosion on terminals, or abnormal LED statuses; use compressed air (30 PSI max) to clean the IP64-sealed housing. Quarterly, test protection logic via the Mark V HMI by simulating overcurrent and phase loss conditions—verify alarms trigger within ≤12ms and relays operate correctly. Annually, update GE DS200DMCAG1AGB firmware via RS-485 and calibrate analog inputs with a precision signal generator to ensure accuracy within ±0.8%. Replace the module with a factory-calibrated unit if output power degrades or fault logging resolution drops below 0.8ms.

Product Guarantee

GE guarantees the reliability and performance of GE DS200DMCAG1AGB with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark V DCS and mid-range motor control systems and can assist with RS-485 configuration, fault diagnosis, and integration of GE DS200DMCAG1AGB. For critical applications (e.g., nuclear power auxiliary pumps), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE DS200DMCAG1AGB’s power handling, protection response time, and IP64 rating. Additionally, GE provides repair services for GE DS200DMCAG1AGB in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for legacy medium-horsepower motor control systems.