Description

Product Overview

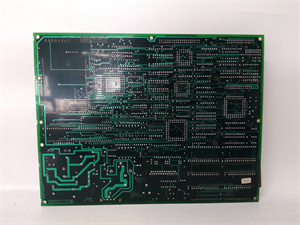

The DS200DMCBG1ABA is part of GE’s Mark V DCS family, specifically engineered to handle discrete (binary) I/O processing for turbine auxiliaries, such as pumps, valves, and relays. Its primary role is to consolidate and condition digital signals from field devices (e.g., limit switches, pressure sensors) before transmitting them to the Mark V controller. The board also sends control commands back to actuators (e.g., motor starters, solenoid valves) based on logic programmed in the DCS.

Key features include:

Rugged Design: Conformal coating and industrial-grade components ensure operation in harsh environments (-40°C to +70°C, high vibration, EMI).

Modular Architecture: VME-style form factor for easy integration into Mark V cabinets, supporting hot-swap capabilities.

Diagnostic Tools: Front-panel LEDs for power, fault, and signal status; reset button for quick troubleshooting.

Configurable Jumpers: 19 jumpers allow customization of signal thresholds, termination resistors, and communication parameters.

Technical Specifications

| Parameter | Value |

| Product Model | DS200DMCBG1ABA |

| Manufacturer | General Electric (GE) |

| Product Type | Discrete I/O Processor Board (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS |

| Input/Output | Supports up to 16 discrete inputs and 8 discrete outputs (configurable via jumpers). |

| Connectors | 3×26-pin, 1×40-pin, and 1xRS-232 port for firmware updates and diagnostics. |

| Power Supply | 24V DC (derived from Mark V power distribution core) |

| Isolation | 2500Vrms galvanic isolation between I/O and logic circuits |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | ~0.8kg (1.76lb) |

DS200DMCBG1ABA

Main Features and Advantages

Precision Signal Processing:

Digitizes analog signals from transducers (e.g., 4-20mA current loops) and converts them into binary values for the Mark V controller.

Filters noise and transient spikes to ensure reliable signal integrity in high-interference environments like turbine halls.

Flexible Configuration:

Jumpers allow users to select input/output voltage levels (24V DC, 125V DC) and configure termination resistors for specific field devices.

RS-232 port enables direct communication with a PC for firmware updates and real-time diagnostics.

Diagnostic Capabilities:

Red and green LEDs indicate power status, signal activity, and fault conditions (e.g., open circuit, short circuit).

Built-in self-test function verifies board health during startup, reducing downtime during maintenance.

Seamless Integration:

Communicates with the Mark V controller via the backplane bus, eliminating the need for external converters.

Works alongside modules like GE DS200TPSAG1A (power supply) and GE DS200TCQAG1AAA (signal conditioning) for a complete I/O solution.

Application Field

The DS200DMCBG1ABA is deployed in industries where the Mark V DCS controls critical equipment:

Power Generation: Manages auxiliary systems in gas/steam turbines (e.g., boiler feedwater pumps, cooling fans) and hydroelectric plants.

Oil & Gas: Controls subsea wellhead pumps, compressor anti-surge valves, and onshore fracturing equipment.

Heavy Industry: Regulates steel mill rolling processes, paper mill pulp mixers, and cement plant conveyors.

Example Use Case:A 500MW combined-cycle plant in Texas used the DS200DMCBG1ABA to monitor pressure switches in the turbine lubrication system. When a switch failed to close during startup, the board triggered an alarm and prevented damage to bearings, saving $150,000 in repairs.

DS200DMCBG1ABA

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply for stable operation.

GE DS200TCQAG1AAA: Digital signal conditioning board for filtering and amplifying inputs.

GE DS200DTBAG1AAA: Digital contact terminal board for terminating field wiring.

GE DS200GDPAG1AHE: Generator protection module that integrates with the DMCBG1ABA for fault shutdowns.

Installation and Maintenance

Installation:

Safety Precautions: Power off the Mark V system and use ESD-safe tools to avoid damaging the board.

Wiring: Connect field devices to the terminal block, ensuring proper polarity and voltage matching.

Configuration: Set jumpers according to the application (e.g., input type, termination) and verify settings via the Mark V HMI.

Maintenance:

Monthly Checks: Inspect LEDs for faults, check connector tightness, and clean dust from the board.

Annual Testing: Use a multimeter to verify power supply and signal levels; replace worn jumpers or fuses as needed.

Firmware Updates: Periodically update firmware via the RS-232 port to ensure compatibility with the Mark V controller.

Product Guarantee

GE provides a 1-year standard warranty for the DS200DMCBG1ABA, covering defects in materials and workmanship. Extended warranties (up to 3 years) are available for critical applications, including on-site commissioning by certified technicians. Repairs are performed in GE-approved facilities, with a 6-month post-repair warranty.

Conclusion

The GE DS200DMCBG1ABA is a reliable and configurable discrete I/O processor board for GE’s Mark V DCS, ensuring precise control and monitoring of auxiliary systems in harsh industrial environments. Its robust design, diagnostic tools, and seamless integration make it a cost-effective solution for extending the operational life of legacy turbine control systems. For detailed configuration and troubleshooting, consult GE’s official documentation or contact their technical support team.