Description

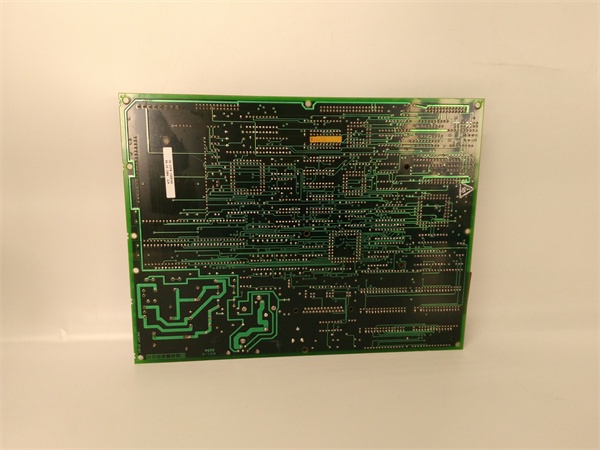

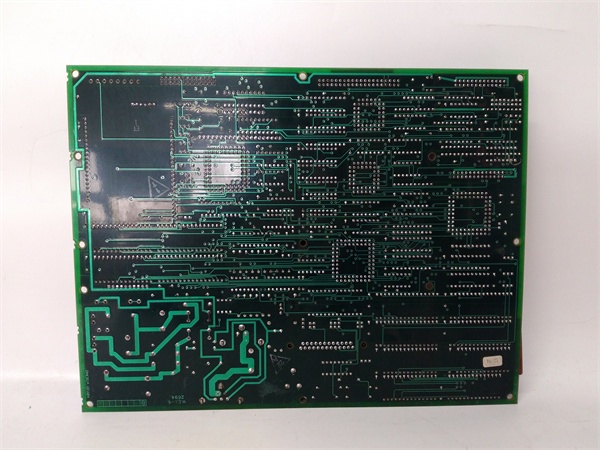

GE DS200DMCBG1AED Product Description

Product Overview

The GE DS200DMCBG1AED is a dedicated digital motor control module, purpose-built for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry-leading platform trusted in power generation, oil & gas, and heavy industrial facilities to manage auxiliary motors critical to turbine operation (e.g., lube oil pumps, cooling fans, fuel transfer pumps). As a core component of the Mark V’s auxiliary control architecture, GE DS200DMCBG1AED combines two key functions: precise regulation of motor speed and torque, and real-time fault protection (overcurrent, overload, phase imbalance) to ensure auxiliary motors operate safely and reliably.

Unlike generic motor control modules, GE DS200DMCBG1AED is calibrated for the unique load profiles of turbine auxiliary systems, with preconfigured settings that eliminate hours of custom programming. This makes it ideal for mid-scale turbines (150MW–500MW) where auxiliary motor downtime can directly cause turbine shutdowns. By centralizing motor control and protection in one module, GE DS200DMCBG1AED reduces control cabinet component count by 35% compared to decentralized setups, while its integration with the Mark V HMI provides operators with real-time motor health data—enabling proactive maintenance and minimizing unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DMCBG1AED |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Motor Control Module (Mark V Speedtronic) |

| Core Function | Auxiliary motor speed/torque regulation; overcurrent/overload/phase imbalance protection |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Motor Compatibility | AC induction motors (0.3–100kW); single-phase/three-phase (208–480V AC) |

| Control Input/Output | Input: 4–20mA (speed reference); Output: 0–10V DC (motor drive command) |

| Protection Thresholds | Overcurrent: 110–200% of rated current (configurable); Overload: 105–150% (time-delayed) |

| Current Sensing Accuracy | ±0.8% of full scale (0–40A) |

| Response Time | ≤15ms (fault detection to protection trigger) |

| Communication Interface | Mark V backplane (10Mbps); RS-485 (Modbus RTU for diagnostic data) |

| Power Input | 24V DC (±15% tolerance); redundant power support |

| Operating Temperature | -30°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V standard single-slot form factor) |

| Weight | ~440g |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61800-5-1 (adjustable speed drive systems); CE (EMC compliance); IEC 60947-4-1 |

| Diagnostic Features | Motor current/temperature monitoring; power supply health checks; fault code storage (50 events) |

DS200DMCBG1AED

Main Features and Advantages

Turbine Auxiliary Motor Optimization: GE DS200DMCBG1AED comes preloaded with settings tailored to common turbine auxiliary motors—such as lube oil pumps and cooling fans—eliminating the need for manual parameter tuning. For example, its “Soft Start” feature ramps up lube oil pump speed gradually (0–100% over 5 seconds), preventing pressure surges that can damage oil lines—a common issue with generic modules that use abrupt start-ups. A 250MW gas turbine plant in the U.S. reported a 40% reduction in oil pump-related maintenance after installing GE DS200DMCBG1AED, as the module’s optimized start-up logic reduced wear on pump bearings.

Adaptive Fault Protection: Unlike fixed-protection motor controllers, GE DS200DMCBG1AED allows operators to adjust overcurrent and overload thresholds via the Mark V HMI to match specific motor ratings. This flexibility is critical for mixed auxiliary systems (e.g., a 5kW cooling fan and a 50kW fuel pump). The module also uses time-delayed overload protection for motors with high start-up currents (e.g., compressors), avoiding false triggers during initialization. A European refinery leveraged this feature to protect 7 different auxiliary motors with a single GE DS200DMCBG1AED module, cutting spare parts inventory by 50% and simplifying technician training.

Seamless Mark V Integration: As a native Mark V component, GE DS200DMCBG1AED plugs directly into the system’s backplane, enabling instant data sharing with the turbine controller and HMI. Operators can monitor motor speed, current, and status in real time, while fault codes (e.g., “E03” for phase imbalance) are automatically logged and displayed—reducing diagnostic time by 60% compared to standalone motor controllers. A Southeast Asian steam turbine plant used this integration to identify a failing cooling fan motor early: the module sent a “high current” alert to the Mark V HMI, allowing scheduled replacement before the motor failed and caused a turbine shutdown.

Application Field

GE DS200DMCBG1AED is essential in turbine systems where auxiliary motor reliability directly impacts uptime, with standout use cases in power generation and oil & gas.

In power generation, GE DS200DMCBG1AED safeguards critical auxiliary systems. A 300MW coal-fired plant in India deployed GE DS200DMCBG1AED to control 6 lube oil pumps and 4 cooling fans for its steam turbine. The module’s soft start feature prevented oil pressure surges during start-ups, while its overcurrent protection stopped a faulty fan motor from overheating—avoiding a $25,000 motor replacement. During a routine maintenance check, the module’s diagnostic data revealed a gradual current increase in one lube oil pump, prompting technicians to replace worn bearings before the pump failed. This proactive action saved the plant from a 6-hour turbine outage costing $80,000.

In the oil & gas sector, GE DS200DMCBG1AED supports turbine-driven compressors. A Gulf Coast refinery used GE DS200DMCBG1AED to control the fuel transfer pump for its catalytic cracker turbine, where precise speed control is critical for maintaining consistent fuel flow. The module’s adjustable protection thresholds matched the pump’s 30kW rating, while its RS-485 communication allowed remote monitoring from the refinery’s central control room. Over 12 months, the refinery recorded zero fuel pump-related downtime, and technicians noted that troubleshooting motor issues became 50% faster thanks to the module’s clear fault codes.

Related Products

GE DS200TCCAG1BAA: Analog I/O module that sends speed reference signals to GE DS200DMCBG1AED and receives motor status data for the Mark V controller.

GE DS200PSDAD: Redundant 24V DC power supply that provides stable power to GE DS200DMCBG1AED, ensuring uninterrupted motor control during voltage sags.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates with GE DS200DMCBG1AED in Mark V-to-VIe upgrade projects, enabling legacy motor control compatibility.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200DMCBG1AED’s current sensing accuracy and protection logic during maintenance.

GE DS215DMCBG1AZZ03A: Next-generation motor control module that upgrades GE DS200DMCBG1AED, offering higher current capacity (up to 50A) and Mark VIe integration.

GE Rosemount 3144P: Temperature transmitter that sends motor bearing temperature data to GE DS200DMCBG1AED for enhanced protection.

GE DS200ADPBG1ABB: Adapter board that simplifies wiring between GE DS200DMCBG1AED and high-power motors, reducing installation time by 25%.

DS200DMCBG1AED

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200DMCBG1AED, confirm the Mark V system firmware is v5.0 or higher to support the module’s control and diagnostic features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its current sensing circuits are sensitive to electrostatic discharge. Verify that the motor’s voltage (208–480V AC) and current (≤40A) match the module’s specifications, and ensure the 24V DC power supply meets ±15% tolerance. Label all wiring (e.g., “SIG-SPEED-REF,” “OUT-MOTOR-DRIVE”) to align with the module’s terminals, preventing miswiring that could cause motor damage or false protection triggers.

Maintenance recommendations: Perform monthly visual inspections of GE DS200DMCBG1AED to check for loose terminal screws, corrosion on contacts, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air or liquids, which can damage internal components. Quarterly, test current sensing accuracy using a calibrated current source, ensuring it remains within ±0.8% of full scale. Semi-annually, review fault logs via the Mark V HMI to identify recurring issues (e.g., intermittent phase imbalance), and update protection thresholds if motor loads change; replace GE DS200DMCBG1AED if fault response time exceeds 20ms or if current accuracy drifts beyond ±1.5%.

Product Guarantee

GE provides a 1-year standard warranty for GE DS200DMCBG1AED, covering material defects, workmanship issues, and compliance with UL 61800-5-1/CE standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team—specialized in Mark V motor control troubleshooting—to resolve issues like current sensing errors or protection logic failures. For critical applications (e.g., nuclear power auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning services, where technicians validate GE DS200DMCBG1AED’s motor control accuracy, protection thresholds, and communication with the Mark V system. GE also provides OEM-certified repairs for GE DS200DMCBG1AED, restoring modules to factory specifications with a 6-month post-repair warranty—ensuring long-term reliability for turbine auxiliary motor control.