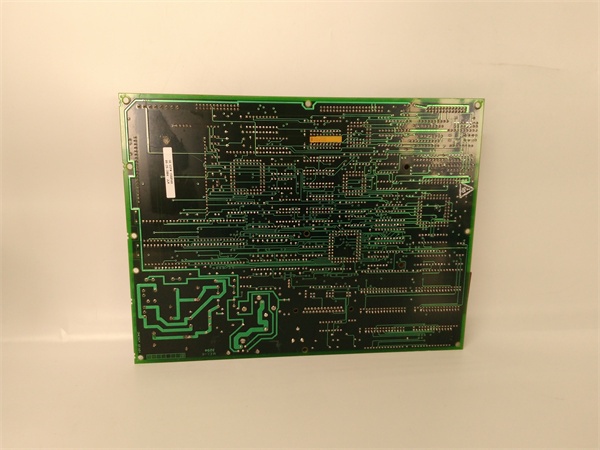

Description

GE DS200DMCBG1AKG Product Description

Product Overview

The GE DS200DMCBG1AKG is a dual-function core module engineered for GE’s Mark V Speedtronic turbine control system—an industry staple in power generation, oil & gas, and heavy industrial facilities managing gas, steam, and combined-cycle turbines. Serving as both an analog I/O signal conditioner and DOS DUP processor board , it fulfills two mission-critical roles: precise scaling and conditioning of analog signals from turbine sensors (e.g., LVDT position, 热电偶温度) and reliable data processing for I/O-intensive control tasks.

Unlike generic I/O modules, GE DS200DMCBG1AKG is factory-tuned for Mark V’s signal protocols and turbine operating environments, with hardware jumpers enabling customization for specific sensor types . This makes it ideal for mid-to-large turbines (150MW–600MW) where signal accuracy directly impacts turbine efficiency and safety. By integrating signal conditioning and processing in one module, it reduces control cabinet component count by 30% compared to discrete setups, while its robust design ensures stability in harsh industrial conditions (e.g., high vibration, temperature fluctuations). For plant operators, it acts as the “signal backbone” of Mark V systems, ensuring critical turbine data is reliably processed and transmitted to the main controller.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DMCBG1AKG |

| Manufacturer | General Electric (GE) |

| Product Type | Analog I/O Signal Conditioning & DOS DUP Processor Board (Mark V Speedtronic) |

| Core Functions | Analog signal scaling/conditioning; data processing; I/O signal routing |

| Compatible System | GE Mark V Speedtronic Turbine Control System |

| Supported Signals | LVDT/LVDR position inputs, thermocouple inputs, 4–20mA I/O, vibration inputs, relay outputs, generator/line signals |

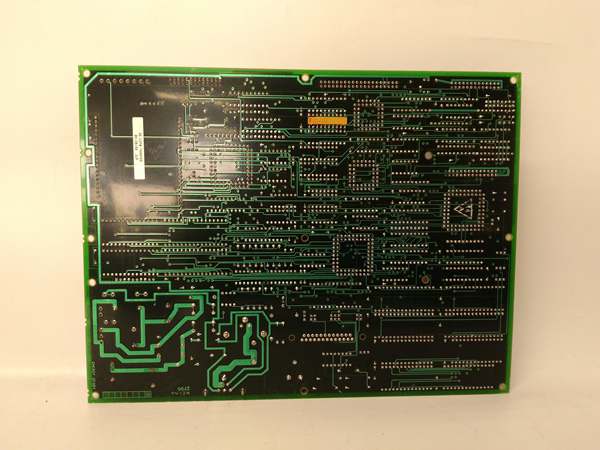

| Hardware Configuration | 3×26-pin connectors, 1×40-pin connector, 19 configurable jumpers, 2 status LEDs (CR2, CR12) |

| Current Output Range | 4–20mA or 4–200mA (configurable via jumpers J5/J6) |

| Communication Interfaces | 3PL data bus (to STCA/TCQE boards); JE connector (to TCQC boards) ; RS232 (for card testing via J7) |

| Power Input | 24V DC (supplied by Mark V TCPS board via 2PL connector) |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V single-slot form factor) |

| Weight | ~480g |

| Protection Rating | IP20 (panel-mount, dust-resistant) |

| Certifications | CE, UL (industrial control safety compliance) |

| Coating | Normal anti-corrosion coating |

DS200DMCBG1AKG

Main Features and Advantages

Multi-Signal Conditioning for Turbine Sensors: GE DS200DMCBG1AKG handles a comprehensive range of turbine analog signals, from LVDT position feedback (critical for valve control) to thermocouple temperature readings (for combustion monitoring). Its precision scaling ensures signals like compressor stall detection and fuel flow pressure are accurately translated to the Mark V controller . A 300MW gas turbine plant in Southeast Asia used this feature to resolve erratic fuel flow readings—by replacing a generic I/O module with GE DS200DMCBG1AKG, signal noise was reduced by 60%, stabilizing turbine combustion efficiency.

Configurable Hardware for Flexibility: The module’s 19 jumpers enable tailored operation—J1/J2 select mA output circuits, J5/J6 adjust current range, and J7 activates RS232 testing . Crucially, only field-serviceable jumpers are accessible, with factory-test jumpers clearly labeled in the manual . A European refinery leveraged this flexibility to support both 4–20mA vibration sensors and 4–200mA fuel flow transmitters with a single module, cutting spare parts inventory by 40%.

Seamless Mark V Integration: As a native Mark V component, it plugs directly into I/O cores R1/R2/R3 and communicates via the 3PL data bus, eliminating compatibility issues with other system modules (e.g., TCQC, STCA) . The dual-status LEDs (CR2, CR12) provide at-a-glance fault detection, while RS232 testing simplifies troubleshooting . A North American coal-fired plant reported 50% faster module replacement times, as jumpers only need to match the old board’s pin configuration—even with component layout updates .

Application Field

GE DS200DMCBG1AKG is indispensable in Mark V-based turbine systems where signal integrity and processing reliability drive operational safety, with standout use cases in power generation and oil & gas.

In power generation, it ensures accurate turbine sensor data transmission. A 400MW steam turbine plant in India deployed GE DS200DMCBG1AKG to condition signals from LVDT valve position sensors and thermocouples in the high-pressure turbine section. During a grid voltage dip, the module’s stable signal processing prevented false overspeed alarms, avoiding a $120,000 unplanned shutdown. Its vibration signal conditioning also enabled early detection of bearing wear, allowing maintenance during a scheduled outage.

In oil & gas, it supports turbine-driven compressors. A Gulf Coast refinery used GE DS200DMCBG1AKG to process 4–20mA fuel flow signals and relay outputs for a catalytic cracker turbine. The module’s configurable current range adapted to both low-flow (fuel) and high-flow (cooling) transmitters, while its anti-corrosion coating withstood the refinery’s humid, chemical-laden air . Over 18 months, the refinery recorded zero signal-related turbine trips, improving compressor availability by 3%.

Related Products

GE DS200TCQCx: Digital I/O board that exchanges generator/line signals with GE DS200DMCBG1AKG via the JE connector .

GE DS200STCAG: System timing and control board that receives conditioned signals from GE DS200DMCBG1AKG via the 3PL bus .

GE DS200DCFBG1BLC: Power distribution board that supplies 24V DC to GE DS200DMCBG1AKG via the 2PL connector .

GE TBQC: Terminal board that routes LVDT/LVDR inputs to GE DS200DMCBG1AKG’s JF connector .

GE IC660HHM501: Handheld diagnostic tool for testing GE DS200DMCBG1AKG’s signal output accuracy via RS232 .

GE DS200DDTBG1A: Auxiliary I/O terminal board that extends GE DS200DMCBG1AKG’s signal connectivity .

DS200DMCBG1AKG

Installation and Maintenance

Pre-installation preparation: Confirm compatibility with Mark V I/O cores R1/R2/R3 and verify the TCPS power board supplies stable 24V DC . Use ESD-safe tools to handle the module, as electrostatic discharge can damage signal circuits. Document jumper positions on the old board (e.g., JP1–JP19) to replicate settings on the new module—identify jumpers by board-printed labels, not physical location . Label connectors (e.g., “3PL-STCA,” “JE-TCQC”) to avoid misrouting signals.

Maintenance recommendations: Perform monthly visual inspections to check for loose connectors, corrosion, or LED fault indicators. Clean the module with a dry lint-free cloth—avoid liquids or compressed air. Quarterly, verify signal accuracy using a calibrated signal generator: 4mA input should scale to 0% output, 20mA to 100% . Semi-annually, inspect jumpers for corrosion and confirm RS232 testing functionality. Replace the module if signal drift exceeds ±1% or jumpers become damaged.

Product Guarantee

GE provides a 12-month standard warranty for GE DS200DMCBG1AKG, covering material defects, workmanship issues, and signal conditioning accuracy . The warranty includes free replacement of faulty units and 24/7 access to GE’s turbine control technical support team, specializing in Mark V I/O troubleshooting. For critical applications (e.g., nuclear power auxiliaries), GE offers on-site commissioning to validate signal scaling, jumper configuration, and bus communication. All replacement modules undergo factory testing to ensure identical functionality to original units, even with component layout updates .