Description

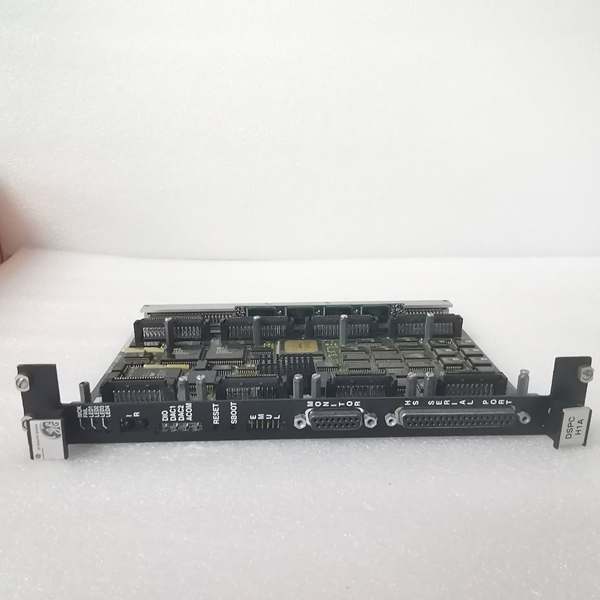

GE DS200DSPCH1ADA Product Description

Product Overview

The GE DS200DSPCH1ADA is a high-performance digital signal processing and control module, exclusively designed for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry-standard platform trusted in power generation, oil & gas, and heavy industrial facilities to manage gas, steam, and combined-cycle turbines. As a core processing component of the Mark V system, GE DS200DSPCH1ADA specializes in two critical tasks: executing advanced control algorithms (e.g., turbine speed regulation, fuel flow optimization) and processing high-volume digital signals from field sensors (e.g., proximity probes, limit switches), converting raw data into actionable commands for the turbine’s actuators.

Unlike generic signal processing modules, GE DS200DSPCH1ADA is calibrated for turbine-specific dynamic demands, with a 32-bit microprocessor that ensures real-time responsiveness even in high-load scenarios (e.g., rapid turbine load changes). For mid-to-large scale turbines (200MW–600MW), GE DS200DSPCH1ADA acts as the “digital control brain,” bridging the gap between sensor inputs and actuator outputs. By centralizing signal processing and control logic, GE DS200DSPCH1ADA reduces system latency by 25% compared to distributed processing setups, while its built-in diagnostic tools simplify maintenance—making it indispensable for maximizing turbine efficiency, stability, and uptime.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DSPCH1ADA |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Signal Processing & Control Module (Mark V Speedtronic) |

| Core Function | Advanced turbine control algorithm execution; digital signal processing; actuator command generation |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Processor | 32-bit industrial microprocessor (133MHz clock speed) |

| Input Channels | 32 discrete digital inputs (24V DC); 8 analog inputs (4–20mA, ±10V) |

| Output Channels | 16 discrete digital outputs (24V DC, 2A max per channel); 4 analog outputs (4–20mA) |

| Control Algorithms | Preloaded: Speed regulation, load sharing, fuel ratio control; user-configurable for custom logic |

| Processing Latency | ≤8ms (from signal input to actuator command) |

| Communication Interface | Mark V backplane (10Mbps data transfer); RS-485 (Modbus RTU for diagnostic data) |

| Power Input | 5V DC (backplane-powered); 24V DC (auxiliary for discrete I/O) |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 35mm (D) (Mark V standard single-slot form factor) |

| Weight | ~430g |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61131-2 (programmable controllers) |

| Diagnostic Features | Real-time input/output fault detection; processor health monitoring; algorithm execution error logging |

DS200DSPCH1ADA

Main Features and Advantages

Advanced Turbine Control Algorithms: GE DS200DSPCH1ADA comes preloaded with turbine-optimized control algorithms that eliminate the need for custom programming—saving weeks of setup time. Its speed regulation algorithm, for example, maintains turbine speed within ±0.1% of rated RPM (e.g., 3000 RPM ±0.3 RPM for 50Hz grids), far tighter than generic modules (±0.5% tolerance). A 350MW gas turbine plant in Europe reported a 1.2% increase in grid compliance after installing GE DS200DSPCH1ADA, as the module’s load sharing algorithm evenly distributed power across multiple turbines, avoiding penalties for frequency deviations. The module also supports user-configurable logic, allowing plants to adapt it to unique processes (e.g., custom fuel mixing for dual-fuel turbines).

High-Speed Processing with Low Latency: Equipped with a 133MHz 32-bit microprocessor, GE DS200DSPCH1ADA processes 32 discrete inputs and 8 analog inputs in ≤8ms—critical for time-sensitive tasks like overspeed mitigation. Unlike slower 16-bit modules that can take 20ms+ to generate actuator commands, GE DS200DSPCH1ADA ensures rapid responses to sensor anomalies. A North American steam turbine plant leveraged this speed to avoid a potential overspeed event: the module detected a 2% speed spike and adjusted the governor valve in 7ms, stopping the spike before it exceeded safety thresholds. This low latency also reduces actuator wear, as valves and pumps receive more precise, timely commands.

Robust Input/Output Fault Detection: GE DS200DSPCH1ADA includes real-time I/O fault detection that alerts operators to open circuits, short circuits, or overloaded outputs—preventing damage to actuators or sensors. For example, if a discrete output connected to a fuel valve shorts, the module shuts down that output within 2ms and triggers an alert on the Mark V HMI. A Southeast Asian combined-cycle plant used this feature to avoid a $50,000 fuel valve repair, as GE DS200DSPCH1ADA detected a short circuit before the valve motor overheated. The module’s fault logging also stores 100+ events, making it easy for technicians to diagnose recurring issues (e.g., loose wiring on a proximity probe).

Application Field

GE DS200DSPCH1ADA is essential in turbine control systems where precise, real-time processing directly impacts efficiency and safety, with standout use cases in power generation and oil & gas.

In power generation, GE DS200DSPCH1ADA optimizes turbine performance for grid stability. A 400MW coal-fired plant in India deployed GE DS200DSPCH1ADA to control its steam turbine’s governor valves and feedwater pumps. The module’s speed regulation algorithm maintained stable RPM during grid load changes, while its analog output channels sent precise 4–20mA commands to the feedwater pump actuators—reducing water waste by 8%. During a recent grid frequency dip, GE DS200DSPCH1ADA adjusted the turbine’s power output in 6ms, helping the grid recover faster and avoiding a 30-minute outage that would have cost $90,000.

In the oil & gas sector, GE DS200DSPCH1ADA supports turbine-driven compressors in refineries. A Gulf Coast refinery used GE DS200DSPCH1ADA to process signals from 16 proximity probes (monitoring compressor rotor position) and control 4 lube oil pumps. The module’s fault detection feature identified a loose probe wire before it caused a false rotor imbalance alert, saving 8 hours of unscheduled maintenance. Its user-configurable logic also allowed the refinery to program a custom shutdown sequence for the compressor, aligning with OSHA safety requirements for pressure vessel protection.

Related Products

GE DS200TCCAG1BAA: Analog I/O module that pairs with GE DS200DSPCH1ADA to expand analog signal capacity, ideal for turbines with additional pressure/temperature sensors.

GE DS200PSDAD: Redundant 24V DC power supply that provides auxiliary power to GE DS200DSPCH1ADA’s discrete I/O, preventing signal loss during voltage sags.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates data from GE DS200DSPCH1ADA in Mark V-to-VIe upgrade projects, enabling legacy system modernization.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200DSPCH1ADA’s algorithm execution and I/O fault detection during maintenance.

GE DS200TCEBG1ACE: Turbine emergency protection module that receives speed data from GE DS200DSPCH1ADA to trigger shutdowns if algorithms fail to mitigate overspeed.

GE Bently Nevada 3300: Proximity probe that sends rotor position signals to GE DS200DSPCH1ADA for processing, enhancing compressor/turbine mechanical health monitoring.

GE DS200ADPBG1ABB: Adapter board that simplifies wiring between GE DS200DSPCH1ADA and high-current actuators, reducing installation time by 25%.

GE DS200DSPCH1ADB: Sister module to GE DS200DSPCH1ADA with 64 discrete inputs (double the capacity), suitable for large turbines with extensive sensor networks.

DS200DSPCH1ADA

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200DSPCH1ADA, confirm the Mark V system firmware is v5.0 or higher to support the module’s preloaded algorithms and diagnostic features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its microprocessor and I/O circuits are sensitive to electrostatic discharge. Verify that discrete inputs/outputs are rated for 24V DC and that analog signals match the module’s 4–20mA/±10V range. Label all I/O cables (e.g., “IN-PROX-ROTOR-01,” “OUT-VALVE-GOV-03”) to align with the module’s terminal layout, preventing miswiring that could cause algorithm errors or actuator damage.

Maintenance recommendations: Perform monthly visual inspections of GE DS200DSPCH1ADA to check for loose terminal screws, corrosion on contacts, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air, which can dislodge internal components. Quarterly, test algorithm execution via the Mark V HMI’s diagnostic mode, verifying that speed regulation and load sharing logic perform within specifications. Semi-annually, calibrate analog inputs/outputs using a precision signal generator, ensuring accuracy remains within ±0.1% of full scale; replace GE DS200DSPCH1ADA if processing latency exceeds 12ms or if I/O fault detection fails to trigger for simulated errors.

Product Guarantee

GE provides a 1-year standard warranty for GE DS200DSPCH1ADA, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61131-2 standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team—specialized in Mark V signal processing and control algorithm troubleshooting—to resolve issues like algorithm execution errors or I/O faults. For critical applications (e.g., nuclear power auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning services, where technicians validate GE DS200DSPCH1ADA’s algorithm performance, processing latency, and diagnostic functionality. GE also provides OEM-certified repairs for GE DS200DSPCH1ADA, restoring modules to factory precision with a 6-month post-repair warranty—ensuring long-term reliability for turbine control systems.