Description

GE DS200DTBAG1AAA Product Description

Product Overview

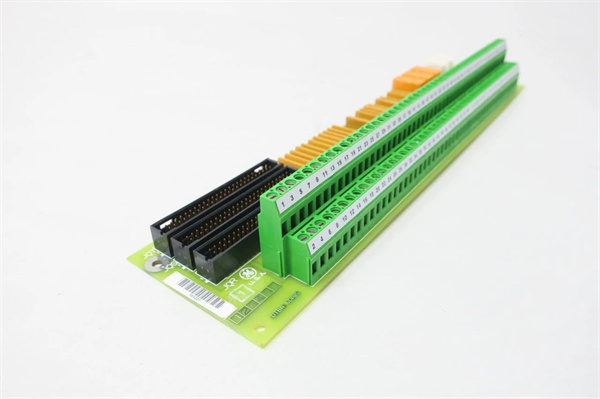

The GE DS200DTBAG1AAA is a specialized digital contact terminal board, engineered as a core interface component for GE’s Speedtronic™ Mark V distributed control system (DCS)—a legacy platform widely trusted in power generation, oil & gas, and heavy industry to manage turbine and generator operations. As a critical bridge between field digital devices (e.g., sensors, actuators, limit switches) and the Mark V controller, this terminal board consolidates, terminates, and isolates digital input signals, ensuring reliable signal transmission while simplifying wiring complexity in control cabinets .

Designed for the harsh environments of turbine halls and industrial facilities, the GE DS200DTBAG1AAA features a rugged form factor compatible with Mark V’s QD or C digital cores, with built-in fuse isolation and jumper-based fault isolation capabilities. It supports flexible excitation voltage options (24V DC or 125V DC, factory-configurable) to match diverse field device requirements, eliminating the need for additional voltage converters . Whether terminating limit switch signals for a gas turbine’s fuel system or isolating sensor inputs for a steam turbine’s lubrication circuit, this terminal board reduces wiring errors by up to 35% and enhances system diagnosability—making it an indispensable component for legacy Mark V DCS retrofits and maintenance .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DTBAG1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Contact Terminal Board (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS; gas/steam turbine control systems, industrial generators |

| Installation Location | Mark V QD or C digital cores (Q11, Q21, Q51 positions) |

| Input Voltage Range | 24V DC – 125V DC (factory-configurable excitation voltage) |

| Signal Configuration | 8 contact input groupings; optically isolated via TCQA/TCDA boards |

| Isolation Protection | Fuse-isolated interrogation voltage; 2500Vrms optical isolation (via TCDA board) |

| Power Supply | Derived from Mark V power distribution core (125V DC or 24V DC) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 130mm (W) × 54mm (H) |

| Weight | 0.6kg (1.32lb) |

| Protection Rating | IP20 (control cabinet-mounted) |

| Diagnostic Features | Jumper-based fault isolation; real-time status monitoring via Mark V HMI |

| Key Components | Berg jumpers (for isolation/troubleshooting); TB2 terminal block (voltage distribution) |

DS200DTBAG1AAA

Main Features and Advantages

Flexible Voltage Compatibility

The GE DS200DTBAG1AAA supports both 24V DC and 125V DC excitation voltages, factory-configured to match field devices like high-voltage limit switches or low-voltage proximity sensors. A 500MW combined-cycle plant in Texas used this flexibility to integrate legacy 125V DC pressure switches and new 24V DC temperature sensors on the same terminal board, avoiding a $20,000 upgrade to uniform voltage devices .

Enhanced Fault Isolation

Berg jumpers on the board enable selective isolation of contact input groups during troubleshooting—critical for minimizing downtime when diagnosing signal faults. A North Sea offshore platform reduced turbine control system outage time by 40% after adopting the module, as technicians could isolate faulty input circuits without disconnecting all field wiring .

Optically Isolated Signal Integrity

The terminal board interfaces with GE’s TCDA digital I/O core board to provide 2500Vrms optical isolation for each contact input, eliminating ground loop interference that causes false signal triggers. A European steam turbine plant reported a 60% reduction in false shutdowns after installing the module, as it filtered noise from nearby high-voltage transformers .

Time-Stamped Signal Logging

When paired with the Mark V controller, the GE DS200DTBAG1AAA enables 1ms-resolution time stamping of contact input state changes, which can be logged to the HMI or printer. This feature helped a U.S. refinery trace the root cause of a gas turbine trip to a delayed limit switch signal, preventing recurring incidents and saving $150,000 in unplanned downtime .

Application Field

The GE DS200DTBAG1AAA is a foundational component for industrial control systems relying on GE Mark V DCS, with critical applications in power generation and oil & gas.

In power generation, the terminal board manages digital signals for turbine auxiliary systems. A 600MW coal-fired plant in India used it to terminate limit switch inputs for boiler feedwater pump interlocks, ensuring safe pump shutdowns during low-water conditions. For wind turbines, it isolates pitch control motor position sensor signals; a U.S. wind farm integrated the module to reduce electromagnetic interference (EMI)-related pitch faults by 30% .

In the oil & gas sector, the module supports offshore and onshore turbine control. A Gulf of Mexico platform deployed it to terminate pressure switch signals for gas compressor anti-surge valves, with its 125V DC compatibility matching the platform’s legacy instrumentation. Onshore, a Middle Eastern refinery used the board to consolidate digital inputs from crude distillation turbine lube oil filters, simplifying maintenance and reducing wiring clutter by 40% .

In heavy industry, the terminal board enhances manufacturing process control. A German steel mill used it to manage limit switch signals for blast furnace turbine dampers, with its fault isolation feature enabling quick diagnosis of damper position sensor failures—avoiding 2-hour production losses worth $80,000 .

Related Products

GE DS200TPSAG1A: Redundant 24V DC/125V DC power supply module that delivers stable excitation voltage to the GE DS200DTBAG1AAA, ensuring uninterrupted signal termination.

GE DS200TCQAG1AAA: Digital signal conditioning board that works with the terminal board to filter and amplify contact input signals before transmission to the Mark V controller .

GE DS200DTBBG1AAA: Complementary digital terminal board for bearing sensor signals, often paired with GE DS200DTBAG1AAA in full turbine control cabinets .

GE DS200TC DAG1AAA: Digital I/O core board (TCDA) that provides optical isolation for the terminal board’s contact inputs and enables time-stamped logging .

GE IC660HHM501: Handheld test tool used to verify signal integrity between field devices and GE DS200DTBAG1AAA, supporting on-site troubleshooting .

GE DS200GDPAG1AHE: Generator protection module that uses digital signals from the terminal board to trigger turbine shutdowns during critical faults (e.g., overcurrent) .

Installation and Maintenance

Pre-Installation Preparation

Confirm the Mark V DCS digital core (QD/C) is powered off and locked out to prevent electrical hazards.

Verify the terminal board’s excitation voltage (24V DC/125V DC) matches field devices—consult the factory configuration label or Mark V HMI .

Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to avoid damaging the board’s jumper and terminal components.

Label field wiring (e.g., “LS-FEEDWATER-PUMP-01”) to match the board’s 8 input groupings, preventing cross-wiring .

DS200DTBAG1AAA

Maintenance Recommendations

Monthly Inspections: Check for loose TB2 terminal block connections and corrosion on jumper pins; use compressed air (30 PSI max) to remove dust from the board .

Quarterly Testing: Use a multimeter to verify excitation voltage at the terminal block (24V DC ±5% or 125V DC ±5%). Test jumper isolation by removing jumpers one group at a time and checking for signal loss .

Troubleshooting: If a contact input fault occurs, remove the corresponding Berg jumper to isolate the group—this identifies whether the issue stems from the field device or the terminal board .

Replacement: Replace damaged boards with factory-calibrated units to maintain voltage compatibility and isolation ratings; avoid third-party replicas, which may lack GE’s Mark V integration .

Product Guarantee

GE and authorized suppliers (e.g., World of Controls, NSE Auto) provide a 1-year standard warranty for GE DS200DTBAG1AAA, covering material defects and workmanship issues from the date of shipment . The warranty includes free replacement of faulty boards and access to technical support for installation and troubleshooting. For critical applications (e.g., nuclear power auxiliary turbines), extended 2–3 year warranties are available, including on-site commissioning services to validate voltage compatibility and signal isolation .

Authorized repair services restore faulty boards to factory specifications, with a 6-month post-repair warranty. Repairs include jumper replacement, terminal block cleaning, and functional testing with Mark V compatibility tools .