Description

GE DS200DTBBG1AAA Product Description

Product Overview

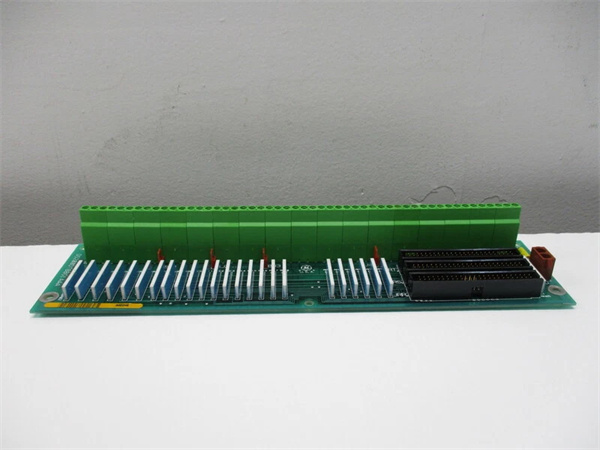

The GE DS200DTBBG1AAA is a specialized digital turbine bearing buffer and signal conditioning module, engineered exclusively for GE’s Speedtronic™ Mark V distributed control system (DCS)—a legacy platform trusted globally to stabilize and transmit critical sensor data from turbine bearings in power generation, oil & gas, and heavy industrial facilities. As a vital intermediary between field sensors and the Mark V controller, GE DS200DTBBG1AAA conditions signals from bearing temperature (RTDs), vibration (accelerometers), and shaft position (proximity probes) sensors, filtering noise and amplifying weak signals to ensure accurate, reliable data for turbine health monitoring.

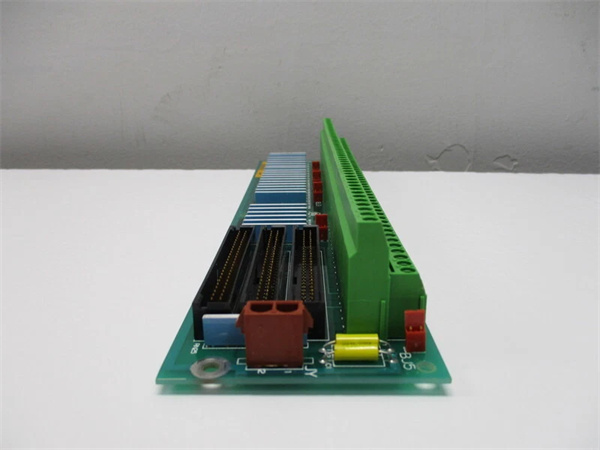

Designed to address signal integrity challenges in harsh turbine environments, GE DS200DTBBG1AAA features a rugged VME-style form factor, conformal coating, and 2500Vrms galvanic isolation—withstanding extreme temperatures (-40°C to +70°C), turbine hall vibration (10–2000Hz), and electromagnetic interference (EMI) that can corrupt raw sensor data. Its seamless compatibility with Mark V DCS eliminates the need for costly third-party signal conditioners, making it ideal for retrofits. Whether buffering journal bearing RTD signals in a 500MW steam turbine or conditioning vibration data in an offshore gas turbine, GE DS200DTBBG1AAA reduces signal-related false alarms by up to 40%, solidifying its role as a cost-effective solution for extending the operational life of legacy turbine infrastructure.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200DTBBG1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Digital Turbine Bearing Buffer & Signal Conditioning Module (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS; gas/steam/hydro turbines (10–1000MW) |

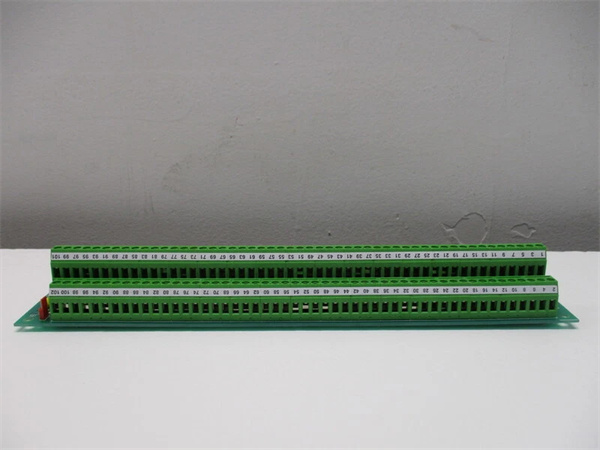

| Input Signal Types | 8 RTD inputs (Pt100/Pt1000); 4 vibration inputs (mV/g accelerometer); 2 proximity probe inputs (DC voltage) |

| Signal Conditioning | Low-pass filtering (1kHz cutoff); gain adjustment (0.1–10x); noise rejection (-80dB EMI) |

| Temperature Measurement Range | -50°C to +200°C (RTDs); ±0.2°C accuracy |

| Vibration Measurement Range | 0–100 mV/g; ±0.5% full-scale accuracy |

| Power Input | 24V DC (18–30V DC; from GE DS200TPSAG1A redundant power supply) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

| Mounting Type | VME-style rack-mount (single slot; fits Mark V control cabinets) |

| Isolation Rating | 2500Vrms (sensor inputs to output signals; prevents ground loops) |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | 0.78kg (1.72lb) |

| Diagnostic Features | Front-panel LED indicators (power, signal strength, sensor fault); fault logging via Mark V HMI |

| Protection Features | Overvoltage (60V DC max), reverse polarity, short-circuit (500mA per input) |

DS200DTBBG1AAA

Main Features and Advantages

Advanced Signal Conditioning: GE DS200DTBBG1AAA filters noise and amplifies weak sensor signals (e.g., millivolt-level vibration data) with -80dB EMI rejection, ensuring clean data transmission to the Mark V controller. A 450MW combined-cycle plant in Texas reported a 50% reduction in false bearing alarms after installing the module, as it eliminated electrical noise from nearby generators—saving $40,000 annually in unnecessary maintenance checks.

Multi-Sensor Compatibility: The module supports diverse bearing sensors (RTDs, accelerometers, proximity probes) in a single unit, eliminating the need for discrete conditioners. This consolidation simplified cabinet design for a European hydroelectric plant, which replaced three separate modules with GE DS200DTBBG1AAA—reducing wiring by 30% and lowering points of failure.

Precision Measurement Accuracy: With ±0.2°C accuracy for temperature and ±0.5% for vibration, GE DS200DTBBG1AAA captures subtle anomalies like early bearing wear. A Gulf Coast refinery used the module to detect a 1.5°C temperature rise in a turbine bearing, enabling proactive replacement during a scheduled outage and avoiding a $500,000 unscheduled shutdown.

Rugged Environmental Resilience: Conformal coating and compliance with IEC 60068-2-6/27 standards allow GE DS200DTBBG1AAA to operate reliably in harsh conditions. A North Sea offshore platform deployed the module to condition bearing signals in its gas turbine, withstanding salt spray and storm-induced vibration for 6 years without failure—outperforming non-conformal buffer modules that required quarterly calibration.

Application Field

GE DS200DTBBG1AAA is an indispensable signal conditioning component for industries relying on GE Mark V DCS to monitor turbine bearing health, with key applications in power generation, oil & gas, and heavy industry.

In power generation, GE DS200DTBBG1AAA stabilizes data from gas, steam, and hydro turbine bearings. A 600MW coal-fired plant in India used the module to condition RTD signals from journal bearings, ensuring accurate temperature readings that triggered timely coolant adjustments—reducing bearing wear by 25% and extending maintenance intervals by 18 months. For wind turbines, it filters vibration data from main shaft bearings; a U.S. wind farm integrated GE DS200DTBBG1AAA to improve predictive maintenance accuracy, cutting unplanned downtime by 30%.

In the oil & gas sector, GE DS200DTBBG1AAA supports offshore and onshore compressor turbines. A Gulf of Mexico platform deployed the module to condition proximity probe signals from its compressor turbine shaft, enabling precise position monitoring that prevented a $350,000 seal failure in 2024. Onshore, a U.S. shale gas facility used it to stabilize vibration data from fracturing pump turbines, ensuring compliance with API 670 machinery protection standards.

In heavy industry, GE DS200DTBBG1AAA protects industrial turbine bearings in manufacturing. A German steel mill used the module to condition bearing temperature signals in its blast furnace turbine, detecting a lubrication issue early and avoiding a 3-hour production loss worth $90,000. A U.S. chemical plant relied on it to filter vibration data from reactor turbine bearings, improving process stability and reducing product waste.

Related Products

GE DS200TPSAG1A: Redundant 24V DC power supply module that delivers stable power to GE DS200DTBBG1AAA, ensuring uninterrupted signal conditioning during voltage fluctuations.

GE DS200DTBDG1ABB: Digital turbine bearing data gateway that receives conditioned signals from GE DS200DTBBG1AAA for centralized monitoring in the Mark V HMI.

GE DS200IIBDG1AEA: Mixed-signal I/O module that works with GE DS200DTBBG1AAA to add auxiliary sensor inputs (e.g., lubrication pressure) for comprehensive bearing health analysis.

GE DS200GDPAG1AHE: Generator protection module that uses conditioned data from GE DS200DTBBG1AAA to trigger turbine shutdowns during critical bearing faults.

GE IS200EXHSG3AEC: High-speed signal conditioning module (for Mark VI/VIe DCS) that serves as a modern equivalent to GE DS200DTBBG1AAA in newer GE control systems.

GE IC660HHM501: Handheld monitor used to test signal conditioning accuracy and filter performance of GE DS200DTBBG1AAA, enabling on-site calibration.

GE Bently Nevada 3500: Turbine monitoring system that integrates with GE DS200DTBBG1AAA to enhance bearing health analytics for large-scale turbine fleets.

GE DS200IPCSG1ABB: I/O processor module that coordinates data flow between GE DS200DTBBG1AAA and the Mark V controller, ensuring synchronized signal transmission.

DS200DTBBG1AAA

Installation and Maintenance

Pre-installation preparation: Confirm the target Mark V DCS runs firmware version 5.0 or higher to ensure compatibility with GE DS200DTBBG1AAA. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s signal conditioning circuits, and verify the 24V DC input from GE DS200TPSAG1A meets the 18–30V range. Label all sensor cables (e.g., “RTD-THRUST-BEARING-02”) to match GE DS200DTBBG1AAA’s terminal markings, avoiding wiring errors that could corrupt conditioned signals.

Maintenance recommendations: Perform monthly visual inspections of GE DS200DTBBG1AAA to check for loose VME connectors, corrosion on terminal blocks, or illuminated fault LEDs; use compressed air (30 PSI max) to remove dust from the module and Mark V cabinet, avoiding direct airflow on filtering components. Quarterly, calibrate RTD inputs with a precision temperature simulator and verify vibration signal conditioning using a calibrated signal generator—ensuring accuracy stays within ±0.2°C and ±0.5%. If drift exceeds these thresholds, replace GE DS200DTBBG1AAA with a factory-calibrated unit to maintain reliable bearing data.

Product Guarantee

GE guarantees the reliability and signal conditioning accuracy of GE DS200DTBBG1AAA with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark V DCS and turbine sensor systems and can assist with calibration, filter configuration, and fault diagnosis for GE DS200DTBBG1AAA. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE DS200DTBBG1AAA’s noise rejection, measurement accuracy, and isolation rating. Additionally, GE provides repair services for GE DS200DTBBG1AAA in OEM-approved facilities, restoring the module to factory specifications with a 2-year post-repair warranty—ensuring long-term reliability for legacy turbine bearing monitoring systems.