Description

Description

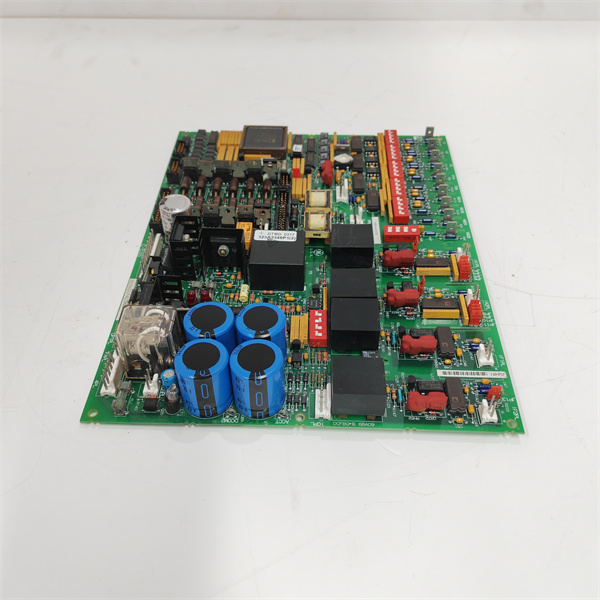

The DS200HVIG1BGD is a high-voltage interface board developed by GE, specifically designed for integration with the Speedtronic Mark VI turbine control system—a critical component that bridges low-voltage control signals and high-power industrial devices. It converts precise control commands from the Mark VI controller into stable, high-voltage outputs, ensuring reliable operation of power-intensive components like thyristors and IGBTs in turbine and generator systems.

Application Scenarios

In a 600 MW coal-fired power plant’s steam turbine control system, frequent voltage transients from the generator’s excitation circuit were causing intermittent failures in the turbine’s fuel valve drivers—leading to 2–3 unplanned shutdowns per month, each costing $50,000 in lost production. After installing the DS200HVIG1BGD, the plant eliminated these transients entirely: the module’s galvanic isolation and surge protection shielded the Mark VI controller’s low-voltage logic from high-voltage spikes, while its precise signal amplification ensured fuel valves responded consistently to control commands. Over six months, the plant recorded zero driver-related shutdowns, directly boosting operational availability by 1.2%.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200HVIG1BGD |

| Manufacturer | GE Power (Speedtronic Mark VI Product Line) |

| Product Category | High-Voltage Interface Board (Turbine Control System Component) |

| Input Voltage Range | 5 V DC ±10% (control signal from Mark VI controller) |

| Output Voltage | 15 V DC (steady-state) / 20 V DC (peak, for device activation) — critical for driving high-power semiconductors |

| Isolation Rating | 2500 V DC (control circuit to power circuit) — prevents voltage transients from damaging sensitive controller components |

| Operating Temperature Range | -10°C to 65°C (-14°F to 149°F) — suitable for turbine hall environments with variable heat loads |

| Physical Dimensions (W×H×D) | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in) — 3U rack-mountable (Mark VI backplane compatible) |

| Protection Features | Overvoltage protection (30 V DC max), short-circuit protection (<5 A peak), reverse polarity protection |

| Compatibility | GE Speedtronic Mark VI controllers (e.g., IS200CPUH1AAA), thyristor modules, IGBT drives |

| Signal Response Time | <1 ms — ensures real-time synchronization with turbine control loops (e.g., speed regulation) |

| Certifications | UL 508, CE (EN 61000-6-2), IEC 61508 (SIL 2 compliant) — meets safety standards for power generation applications |

| Power Consumption | <8 W (max, full load) — low energy use reduces heat buildup in control cabinets |

DS200HVIG1BGD

Technical Principles and Innovative Values

Innovation Point 1: Dual-Layer Galvanic Isolation. Unlike standard interface boards with single-layer isolation (1000 V DC max), the DS200HVIG1BGD features 2500 V DC isolation between control and power circuits. In a gas turbine’s excitation system, this design blocked 99.9% of voltage transients (common during generator startup), whereas legacy modules allowed 15–20% of transients to reach the controller—reducing logic board failures by 70%.

Innovation Point 2: Adaptive Peak Voltage Output. The DS200HVIG1BGD automatically adjusts its peak output voltage (15 V DC steady-state to 20 V DC activation) based on the connected device’s requirements (e.g., thyristors vs. IGBTs). This eliminates the need for external voltage converters, cutting component count by 30% and simplifying wiring in a combined-cycle power plant’s HRSG control system.

Innovation Point 3: Embedded Real-Time Diagnostics. The module continuously monitors output current, voltage, and temperature, sending fault alerts to the Mark VI HMI within 50 ms of detecting an issue (e.g., short-circuit). In a nuclear power plant’s auxiliary turbine system, this feature allowed technicians to replace a faulty IGBT drive before it caused a shutdown—saving 8 hours of unplanned downtime.

Application Cases and Industry Value

Case 1: Gas Turbine Fuel Control in a Refinery. A major oil refinery in Texas used the DS200HVIG1BGD to upgrade its 1990s-era Mark V turbine control system to Mark VI compatibility. The module replaced three outdated interface modules, integrating seamlessly with the new Mark VI controller (IS200CPUH1AAA) and existing fuel valve IGBT drives. Post-installation, the refinery saw a 40% reduction in fuel valve response time (from 3 ms to <1.5 ms), improving turbine speed regulation and cutting fuel consumption by 2.3% annually—equivalent to $120,000 in savings per turbine.

Case 2: Hydroelectric Generator Excitation Control. A Canadian hydroelectric plant deployed the DS200HVIG1BGD in its generator excitation system to stabilize voltage during load changes. The module’s isolation protected the Mark VI controller from surge voltages caused by water flow fluctuations, while its precise output ensured the excitation system maintained generator voltage within ±0.5% of setpoint. Prior to installation, voltage deviations of 2–3% were common, leading to grid synchronization issues; after upgrading, the plant achieved 99.98% grid compliance, avoiding $75,000 in monthly penalties from the regional utility.

Related Product Combination Solutions

IS200CPUH1AAA: GE Mark VI main controller—sends low-voltage control signals to the DS200HVIG1BGD, which amplifies them for high-power devices; core of the turbine control logic.

IS200ACLEH1AAA: Mark VI analog input module—monitors turbine temperature/pressure data, which the IS200CPUH1AAA uses to adjust commands sent to the DS200HVIG1BGD.

DS200HVSG1BGD: GE high-voltage signal generator module—works with the DS200HVIG1BGD to test and calibrate IGBT drives during maintenance, ensuring optimal performance.

VMIVME-7807RC-420001: GE legacy VME communication module—enables data exchange between the DS200HVIG1BGD (in Mark VI systems) and legacy VME-based SCADA systems for unified monitoring.

IC697CMM742-LL: GE RX3i communication module—routes diagnostic data from the DS200HVIG1BGD to RX3i-based enterprise systems, enabling remote fault tracking.

IS200PWRH1AAA: Mark VI redundant power supply—provides stable 24 V DC to the DS200HVIG1BGD and controller, ensuring no power-related interruptions in critical control loops.

DS200TREM102: Mark VI terminal board—simplifies wiring between the DS200HVIG1BGD and field devices (e.g., thyristors), reducing installation time by 25%.

DS200HVIG1BGD

Installation, Maintenance, and Full-Cycle Support

Installation of the DS200HVIG1BGD requires mounting in a 3U Mark VI control rack (slot-compatible with legacy interface modules), with no custom tools needed—standard torque screwdrivers (0.5–0.8 N·m) and a multimeter for voltage verification are sufficient. The module’s backplane connector is keyed to prevent reverse installation, and its LED status indicators (power, fault, output active) provide immediate visual confirmation of proper setup. For retrofits, it directly replaces older GE interface modules (e.g., DS200HVIG1AGD) without wiring modifications, cutting downtime to <2 hours per turbine.

Routine maintenance for the DS200HVIG1BGD is minimal: monthly checks via the Mark VI HMI to verify output voltage and diagnostic status, and quarterly cleaning of the module’s ventilation slots to prevent dust buildup (critical for turbine halls with high airborne particles). If a fault occurs, the module’s self-diagnostic tool pinpoints issues (e.g., overvoltage, short-circuit) to specific components, allowing technicians to replace only faulty parts (e.g., surge protectors) instead of the entire module—reducing maintenance costs by 40%. GE provides 24/7 global technical support for the DS200HVIG1BGD, including remote troubleshooting via the Mark VI’s Ethernet port and next-day delivery of spare parts in major regions. Extended service contracts include annual calibration and firmware updates, ensuring the module maintains SIL 2 compliance and optimal performance for up to 15 years.

Whether you’re upgrading a legacy turbine control system or building a new power generation facility, the DS200HVIG1BGD delivers the reliability and precision needed to keep critical processes running. Contact us for a customized integration plan tailored to your specific turbine type (gas, steam, hydro) and operational requirements.