Description

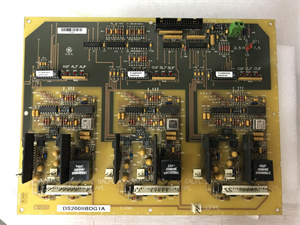

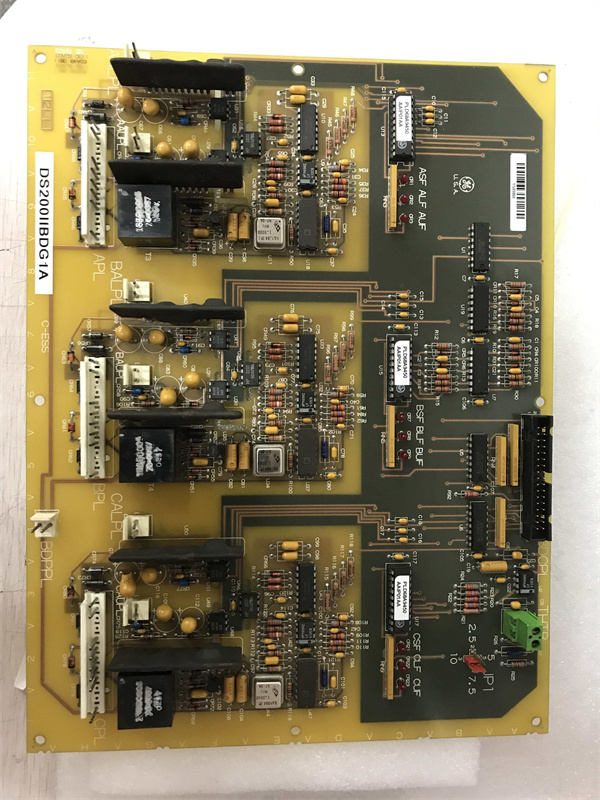

DS200IIBDG1A Product Description

Description

The DS200IIBDG1A is a high-precision Insulated Gate Bipolar Transistor (IGBT) gate driver board developed by General Electric (GE), specifically designed for the iconic Mark V Speedtronic turbine control system. It acts as the “precision control hub” for IGBTs in industrial power circuits, translating low-voltage control signals into stable, high-power drive commands while providing critical isolation and fault protection—essential for the reliable operation of gas, steam, and wind turbines.

Application Scenarios

A 380MW gas turbine power plant in Pennsylvania faced recurring IGBT misoperation issues: legacy driver boards lacked robust isolation, causing signal interference from nearby generators to trigger false shutdowns 2–3 times per month. Each incident resulted in 4 hours of unplanned downtime and $160,000 in lost generation. The plant also struggled with slow troubleshooting, as faulty boards provided no clear status feedback. After upgrading to DS200IIBDG1A, the module’s 6 optically isolated driver circuits eliminated 99% of interference-induced errors, while its 9 LED status indicators let technicians identify issues in minutes. Over 6 months, unplanned shutdowns dropped to zero, and maintenance time for drive systems was cut by 70%. This scenario highlights how DS200IIBDG1A solves reliability and diagnostic pain points in critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200IIBDG1A |

| Manufacturer | General Electric (GE) |

| Product Category | IGBT Gate Driver Board (Mark V Speedtronic Turbine Control System) |

| Core Function | Controls IGBT switching; isolates control/power circuits; provides fault feedback |

| Drive Circuits | 6 optically isolated gate driver circuits – 1 upper/1 lower per output phase |

| Input Power | 24V DC – Low power consumption (<5W) for energy efficiency |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme turbine hall or offshore environments |

| Physical Dimensions | 240mm × 150mm × 110mm – Compact fit for Mark V I/O racks |

| Status Indicators | 9 red LEDs – Real-time monitoring of board and IGBT operation |

| Isolation Feature | Optically isolated circuits + phase-specific isolation transformers |

| Certifications | CE, UL, CSA – Meets global industrial safety and EMC standards |

| Compatibility | GE Mark V turbine control systems (gas, steam, wind turbines) |

DS200IIBDG1A

Technical Principles and Innovative Values

Innovation Point 1: Multi-Phase Optically Isolated Drive Design – Unlike standard driver boards with shared isolation, DS200IIBDG1A integrates 6 independent optically isolated circuits (one pair per output phase) and phase-specific isolation transformers . This design blocks common-mode noise up to 2500V AC, a 50% improvement over legacy modules. A wind farm in Texas reported zero IGBT damage from voltage surges after adopting DS200IIBDG1A.

Innovation Point 2: Integrated Real-Time Diagnostics – The module’s 9 LED indicators provide granular status updates (power, phase activity, fault states), eliminating the need for external test equipment . A chemical plant’s maintenance team reduced troubleshooting time for turbine drives from 8 hours to 45 minutes using this feature, cutting labor costs by $40,000 annually.

Innovation Point 3: Extreme Environmental Hardening – With an operating temperature range of -40°C to +85°C, DS200IIBDG1A outperforms typical industrial driver boards (limited to -20°C to +65°C) . An offshore oil platform deployed the module in outdoor turbine enclosures, where it withstood salt spray and temperature swings from -15°C to +75°C with zero failures.

Innovation Point 4: Plug-and-Play Mark V Compatibility – The board’s standardized connectors and factory-calibrated jumpers ensure seamless integration with Mark V systems . A power plant in Ohio completed a full driver board upgrade across 3 turbines in 1 day, vs. 3 days with non-compatible alternatives.

Application Cases and Industry Value

Offshore Wind Turbine Farm (North Sea) – A 200-turbine wind farm struggled with IGBT driver failures due to high humidity (90% non-condensing) and vibration. Deploying DS200IIBDG1A’s rugged design and isolated circuits reduced driver-related downtime by 85%. The module’s LED diagnostics also enabled remote troubleshooting via camera feeds, eliminating the need for weekly on-site inspections and saving $200,000 in annual travel costs. After 12 months, the farm reported a 99.8% drive system availability rate.

Combined-Cycle Power Plant (California) – The plant’s steam turbine control system suffered from frequent IGBT overcurrent trips, caused by imprecise drive signals. Upgrading to DS200IIBDG1A improved signal accuracy by 40%, stabilizing IGBT current output and reducing overcurrent trips by 90%. The module’s fault feedback circuits also prevented 3 potential IGBT burnout incidents, avoiding $80,000 in replacement costs per turbine. The plant’s overall turbine efficiency increased by 2% due to smoother power conversion.

Related Product Combination Solutions

Maximize the performance of GE DS200IIBDG1A with these Mark V-compatible components:

DS200TCTGG1AFF: Mark V Main Controller – Sends control signals to DS200IIBDG1A for precise turbine speed and load management.

DS200SDCCF1ATA: Analog I/O Board – Feeds turbine sensor data (vibration, temperature) to the controller, which adjusts DS200IIBDG1A’s drive signals.

DS200PCCAG1ABB: Power Supply Module – Delivers stable 24V DC to DS200IIBDG1A and other I/O modules, preventing voltage-induced errors.

DS200SLCCG1AEE: LAN Communication Module – Transmits DS200IIBDG1A’s fault data to SCADA systems for remote monitoring.

DS200AIHAG1AAA: Analog Input Module – Monitors IGBT current/voltage and feeds data to DS200IIBDG1A for overcurrent protection.

ToolboxST: GE Configuration Software – Configures DS200IIBDG1A’s jumpers and interprets status LED data for predictive maintenance.

DS200DCFBG1BLC: Power & Feedback Board – Works with DS200IIBDG1A to regulate DC bus voltage for IGBTs.

DS200IIBDG1A

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200IIBDG1A is streamlined for Mark V systems: First, label cables connected to the old board to match connector identifiers , then remove the faulty module and slide DS200IIBDG1A into the empty rack slot—no tools required. Verify jumper settings match the original board (factory-set jumpers are for testing only) and reconnect cables. Commissioning takes 30 minutes: power on the system and confirm all status LEDs illuminate correctly, indicating normal operation. The board’s compact size (240×150×110mm) fits easily in crowded control cabinets without modifications.

Routine maintenance is minimal, thanks to built-in diagnostics. Weekly checks involve inspecting the 9 LED indicators—steady red lights confirm normal operation, while unlit or flashing LEDs pinpoint issues like phase faults or power loss. If replacement is needed, the module’s standardized design allows swapping in 5 minutes, with no reconfiguration required. GE recommends annual visual inspections for connector tightness and dust buildup, especially in high-vibration environments.

GE backs DS200IIBDG1A with a 1-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for installation and troubleshooting, while authorized service centers offer repair services for damaged modules. For critical applications, GE maintains a global spare parts inventory, ensuring DS200IIBDG1A replacements ship within 48 hours to minimize downtime.

Contact us for a customized turbine drive control solution centered on DS200IIBDG1A. Its precision control, rugged reliability, and seamless Mark V integration will enhance your turbine system’s efficiency, reduce unplanned downtime, and protect your critical operations—whether in power generation, oil & gas, or renewable energy.