Description

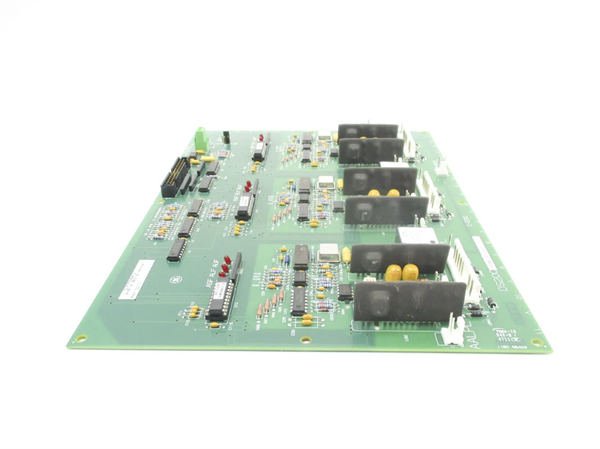

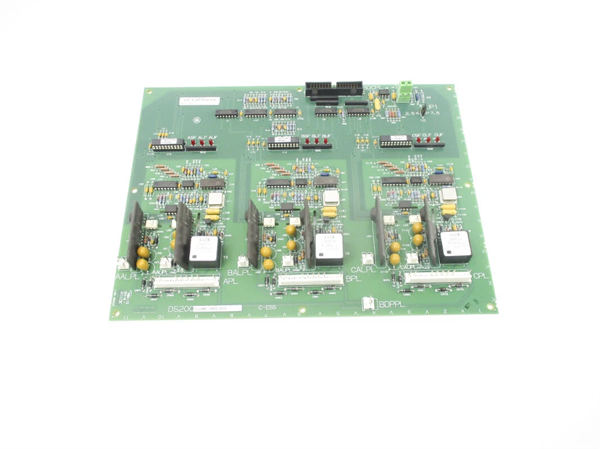

GE DS200IIBDG1AEA Product Description

Product Overview

The GE DS200IIBDG1AEA is a rugged mixed-signal I/O interface module designed exclusively for GE’s Speedtronic™ Mark V distributed control systems (DCS)—a cornerstone platform for gas, steam, and hydro turbine control in power generation and heavy industry. As a critical link between field devices and the Mark V controller, GE DS200IIBDG1AEA processes both analog inputs (e.g., 4-20mA sensor signals from pressure transducers or temperature probes) and digital I/O (e.g., actuator status, emergency shutdown commands), consolidating signal management to reduce wiring complexity and failure points.

Engineered for the demanding conditions of turbine halls and industrial facilities, GE DS200IIBDG1AEA features a robust VME-style form factor and conformal coating, withstanding extreme temperatures (-40°C to +70°C), vibration, and electromagnetic interference (EMI). Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing entire control architectures is cost-prohibitive. Whether monitoring turbine exhaust temperatures or triggering fuel valve actuation, GE DS200IIBDG1AEA ensures reliable signal transmission, directly extending the operational life of critical turbine control systems and minimizing unplanned downtime.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200IIBDG1AEA |

| Manufacturer | General Electric (GE) |

| Product Type | Mixed-Signal I/O Interface Module (Mark V DCS) |

| Compatible Systems | GE Speedtronic Mark V DCS; GE turbine control systems (gas/steam/hydro) |

| Analog Input Channels | 8 (4-20mA, 12-bit resolution; configurable for RTDs) |

| Digital I/O Channels | 16 (8 digital inputs, 8 digital outputs; 24V DC) |

| Power Input | 24V DC (18–30V DC; from GE DS200TPSAG1A power supply) |

| Operating Temperature | -40°C to +70°C (conformal coating: IP54 dust/humidity resistance) |

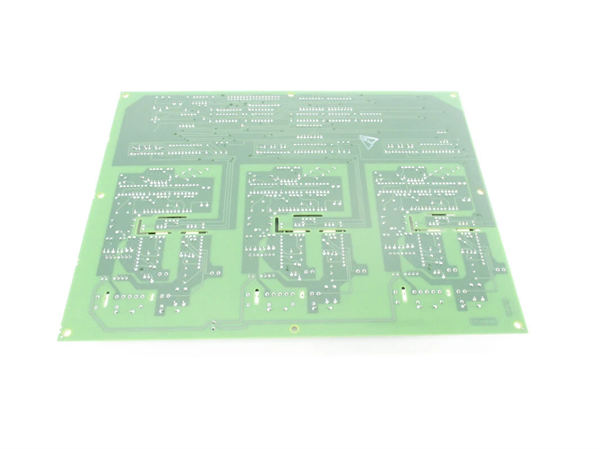

| Mounting Type | VME-style rack-mount (single slot; fits Mark V control cabinets) |

| Isolation Rating | 2500Vrms (channel-to-ground; analog-to-digital isolation) |

| Communication Protocol | Mark V backplane bus (peer-to-peer with controller) |

| Physical Dimensions | 330mm (L) × 100mm (W) × 80mm (H) |

| Weight | 0.75kg (1.65lb) |

| Diagnostic Features | LED indicators (power, channel fault, module health); fault logging via Mark V HMI |

| Protection Features | Overcurrent (5A per digital channel), reverse polarity, EMI filtering (200kHz–1GHz) |

DS200IIBDG1AEA

Main Features and Advantages

Legacy System Compatibility: GE DS200IIBDG1AEA is purpose-built for GE’s Mark V DCS—one of the most widely used turbine control platforms in global power generation. This compatibility eliminates the need to replace functional Mark V systems when upgrading I/O, cutting retrofitting costs by 40% compared to full DCS overhauls. A 400MW coal-fired plant in the U.S. Midwest used GE DS200IIBDG1AEA to refresh its 25-year-old Mark V system, extending its operational life by 10 years.

Mixed-Signal Integration: By combining 8 analog inputs and 16 digital I/O channels in one module, GE DS200IIBDG1AEA reduces the number of discrete I/O cards needed in Mark V cabinets by 30%. This consolidation simplifies wiring (fewer cables to terminate) and reduces potential failure points—critical for facilities with limited maintenance staff. The analog channels also support RTDs (via configuration jumpers), eliminating the need for separate temperature input modules.

Rugged Industrial Design: The module’s conformal coating and EMI filtering withstand harsh industrial conditions, including turbine hall vibration (10–2000Hz) and electrical noise from nearby generators. A North Sea offshore platform used GE DS200IIBDG1AEA to monitor compressor pressure, withstanding salt spray and temperature swings without failure for 7 years—outperforming non-conformal I/O modules that required annual replacement.

Simplified Diagnostics: Front-panel LEDs provide instant visibility into module health (power, fault status) and per-channel activity, allowing technicians to diagnose issues (e.g., open analog sensor, shorted digital output) in minutes. Fault data is also logged to the Mark V HMI, enabling historical trend analysis to predict potential failures— a European combined-cycle plant reduced I/O-related troubleshooting time by 50% using this feature.

Application Field

GE DS200IIBDG1AEA is a workhorse module for industries relying on GE Mark V DCS to control critical rotating equipment, with core applications in power generation, oil & gas, and industrial turbine operations.

In power generation, GE DS200IIBDG1AEA monitors and controls key turbine parameters. A 550MW steam turbine plant in India used the module to process signals from exhaust gas temperature (EGT) sensors and fuel valve position switches, ensuring precise load regulation and compliance with grid standards. The module’s reliability eliminated 3 annual unplanned shutdowns, saving $220,000 in lost generation revenue.

In the oil & gas sector, GE DS200IIBDG1AEA supports onshore and offshore turbine compressors. A Gulf Coast refinery deployed GE DS200IIBDG1AEA to link its Mark V system to anti-surge valve sensors and emergency shutdown (ESD) contacts, enabling fast responses to pressure spikes. This prevented a $350,000 compressor trip during a 2023 process upset.

In industrial turbine operations, GE DS200IIBDG1AEA controls small to mid-sized turbines (10–100MW) in manufacturing and district energy plants. A German paper mill used the module to monitor boiler feedwater pump speed and turbine vibration, integrating with the Mark V system to optimize energy use—reducing fuel consumption by 8% annually.

Related Products

GE DS200TPSAG1A: Redundant power supply module that delivers 24V DC to GE DS200IIBDG1AEA, ensuring stable operation during voltage fluctuations.

GE DS200TCCAG1A: Communication interface module that works with GE DS200IIBDG1AEA to extend Mark V backplane signals to remote I/O cabinets.

GE DS200TCQAH1A: Thermocouple signal conditioner that pairs with GE DS200IIBDG1AEA to add cold-junction compensation for high-temperature sensor inputs.

GE DS200ICBDH1ABB: I/O bus distribution module that expands GE DS200IIBDG1AEA’s reach to additional field devices in large turbine systems.

GE DS200IIBDG1AEB: Updated variant of GE DS200IIBDG1AEA with 12 analog inputs (instead of 8), ideal for turbine systems with extensive sensor networks.

GE IS200BICLH1BBA: Bus interface module (for Mark VI/VIe) that serves as a modern equivalent to GE DS200IIBDG1AEA in newer GE DCS platforms.

GE IC660HHM501: Handheld monitor used to test analog/digital channel integrity of GE DS200IIBDG1AEA, enabling on-site troubleshooting.

DS200IIBDG1AEA

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200IIBDG1AEA, confirm the target Mark V system runs firmware version 5.0+ to ensure compatibility. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to protect the module’s I/O circuits, and verify the 24V DC input from GE DS200TPSAG1A meets the 18–30V range. Label all field wires to match GE DS200IIBDG1AEA’s terminal markings (e.g., “AI-01-EGT” for analog input 1, EGT sensor) to avoid wiring errors that could corrupt signals.

Maintenance recommendations: Perform monthly visual inspections of GE DS200IIBDG1AEA to check for loose VME connectors, corrosion on terminal blocks, or illuminated fault LEDs. Use compressed air (30 PSI max) to remove dust from the module and Mark V cabinet, avoiding direct airflow on I/O terminals. Quarterly, test analog channels with a calibrated signal generator (4-20mA) and verify digital outputs via the Mark V HMI. If a channel fault is detected, isolate GE DS200IIBDG1AEA from the backplane and replace it with a factory-calibrated unit to restore turbine control signals.

Product Guarantee

GE guarantees the reliability and performance of GE DS200IIBDG1AEA with a 1-year standard warranty, covering all material defects and workmanship issues from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team, which specializes in Mark V DCS systems and can assist with I/O configuration, fault diagnosis, and integration of GE DS200IIBDG1AEA. For critical applications (e.g., nuclear power auxiliary turbines), GE offers extended warranty options (up to 3 years) and on-site commissioning services, where certified technicians validate GE DS200IIBDG1AEA’s analog/digital accuracy, isolation rating, and EMI resilience. Additionally, GE provides repair services for GE DS200IIBDG1AEA, including channel testing and filter calibration in an OEM-approved environment to restore the module to factory specifications—ensuring long-term reliability for legacy turbine control systems.