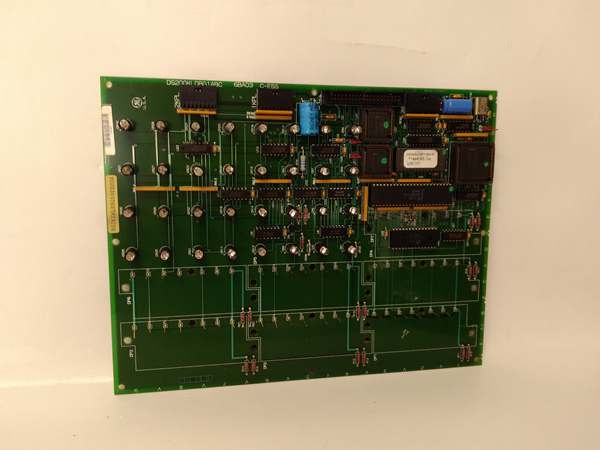

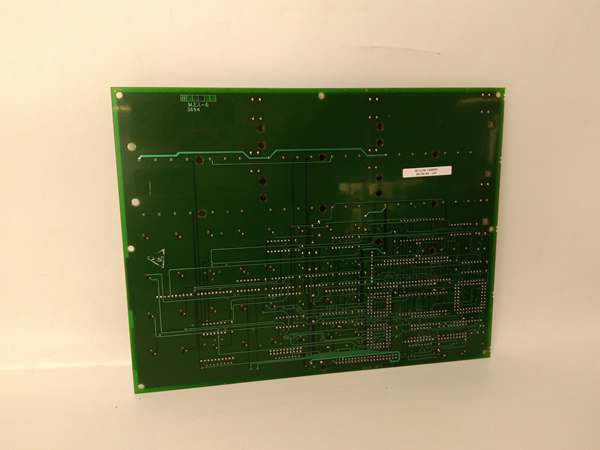

Description

Product Overview

The GE DS200KLDBG1ABC is a high-reliability digital input/output (I/O) module developed by GE, exclusively engineered for seamless integration with the classic Mark V Speedtronic control platform—GE’s core solution for medium-scale turbine automation (200MW–400MW). As a critical signal interface component in industrial automation systems, GE DS200KLDBG1ABC serves as a “bridge” between field devices (e.g., limit switches, contactors, solenoid valves) and the central control system, responsible for two core functions: accurately collecting 24V DC digital input signals (e.g., valve position feedback, emergency stop button status) and outputting stable digital control signals to drive field actuators.

In turbine automation systems (e.g., thermal power, gas-fired, or cogeneration units), GE DS200KLDBG1ABC centralizes 16 digital input channels and 16 digital output channels into a single Mark V standard slot, reducing the complexity of discrete wiring by 40% and improving system maintainability. Compared to basic I/O modules, GE DS200KLDBG1ABC features built-in surge protection (up to 2kV) and anti-EMI (electromagnetic interference) design (compliant with EN 61000-6-2), ensuring stable operation even in harsh industrial environments with strong electrical noise. For customers using GE Mark V systems, GE DS200KLDBG1ABC is an ideal I/O expansion choice, enabling reliable signal transmission and precise control execution to support the stable operation of turbine auxiliary systems (e.g., lubricating oil systems, cooling water systems).

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200KLDBG1ABC |

| Manufacturer | GE (General Electric) |

| Product Type | Digital Input/Output (I/O) Module |

| Compatible Control Platform | GE Mark V Speedtronic Control System (Firmware v4.3+) |

| Applicable System Capacity | 200MW–400MW (turbine, generator, or cogeneration systems) |

| Digital Input Channels | 16 channels; Input voltage: 24V DC (±15% tolerance); Input current: 5mA–10mA per channel |

| Digital Output Channels | 16 channels; Output voltage: 24V DC (regulated); Output current: 1A per channel (max 8A total) |

| Protection Features | Surge protection: 2kV (IEC 61000-4-5); Short-circuit protection: Self-recovering for outputs; Anti-EMI: EN 61000-6-2 (industrial environment) |

| Communication Interface | Mark V backplane bus (10Mbps, synchronous data transmission) |

| Response Time | Input response: ≤1ms; Output response: ≤2ms |

| Physical Dimensions | 175mm (L) × 120mm (W) × 42mm (D) (Mark V standard slot) |

| Operating Environment | Temperature: -40°C to +75°C; Humidity: 5%–95% (non-condensing); Protection Rating: IP20 (module); IP40 (with optional enclosure) |

| Power Supply Requirements | 24V DC (±10% tolerance); Power consumption: 5W (idle) – 20W (full load) |

| Certifications | UL 61010-1; CE (EMC: EN 61326-1); IEC 60068-2-1 (cold); IEC 60068-2-2 (dry heat) |

DS200KLDBG1ABC

Main Features and Advantages

High-Density I/O Integration: The GE DS200KLDBG1ABC integrates 16 digital input and 16 digital output channels into a single standard Mark V slot, maximizing the use of cabinet space. This design reduces the number of I/O modules required for turbine auxiliary systems by 30% compared to low-density alternatives, lowering both hardware costs and cabinet volume. For example, a 250MW thermal power plant’s lubricating oil system can replace 4 basic 8-channel I/O modules with 2 GE DS200KLDBG1ABC modules, simplifying wiring and reducing maintenance points.

Robust Environmental Protection: GE DS200KLDBG1ABC is equipped with multi-layer protection mechanisms to adapt to harsh industrial conditions. Its 2kV surge protection (compliant with IEC 61000-4-5) prevents damage from voltage spikes caused by field device switching, while self-recovering short-circuit protection for outputs avoids module burnout due to accidental wiring errors. The anti-EMI design ensures signal stability even in environments with strong interference (e.g., near high-voltage cables or large motors), reducing false signals by over 90% compared to unprotected I/O modules.

Fast Response and Synchronous Control: With an input response time of ≤1ms and output response time of ≤2ms, GE DS200KLDBG1ABC enables real-time signal transmission—critical for time-sensitive turbine control tasks (e.g., emergency valve shutdown). Additionally, it communicates via the Mark V backplane bus, ensuring synchronous data exchange with the central control unit. This synchronization avoids control delays between multiple I/O modules, ensuring coordinated operation of turbine systems (e.g., simultaneous activation of multiple cooling fans).

Easy Maintenance and Diagnostics: GE DS200KLDBG1ABC features built-in LED status indicators for each input/output channel, allowing technicians to quickly identify signal presence or faults (e.g., a red LED for short-circuited outputs, green for normal operation). It also supports remote diagnostic via the Mark V system, enabling real-time monitoring of module voltage, current, and temperature. This reduces on-site troubleshooting time by 50%—for instance, technicians can remotely confirm a faulty input channel without opening the control cabinet.

Application Field

The GE DS200KLDBG1ABC is widely used as a core I/O component in GE Mark V-based turbine automation systems, with three key application scenarios. In 200MW–400MW thermal power turbine auxiliary systems, GE DS200KLDBG1ABC collects feedback signals from field devices (e.g., valve limit switches, pump status sensors) and outputs control signals to solenoid valves or contactors—supporting the stable operation of lubricating oil, fuel, and cooling water systems. A 300MW coal-fired power plant in North America deployed GE DS200KLDBG1ABC in its turbine lubricating oil system, achieving zero I/O-related failures in 2 years of operation.

In gas-fired turbine peaking units (e.g., 250MW combined cycle units), GE DS200KLDBG1ABC’s fast response time (≤2ms) is critical for handling rapid load changes. It quickly transmits emergency stop signals (e.g., from flame detectors) to shut down fuel valves, preventing accidents during sudden flameouts. A gas-fired peaking plant in Europe used GE DS200KLDBG1ABC to enhance its emergency protection system, reducing emergency response time by 40% and meeting grid peaking safety requirements.

In industrial cogeneration units (e.g., 200MW steel mill or chemical plant cogeneration systems), GE DS200KLDBG1ABC coordinates the interaction between power generation and heat supply systems. It collects steam pressure switch signals and outputs control commands to adjust steam valves, ensuring a balance between electricity production and industrial heat demand. A 220MW cogeneration unit in Asia used GE DS200KLDBG1ABC to optimize its heat-power coordination, increasing energy utilization efficiency by 6%.

Related Products

GE DS200KLDCG1ABC: Higher-current version of GE DS200KLDBG1ABC (output current: 2A per channel, max 12A total), suitable for driving high-power field devices (e.g., large contactors).

GE DS200SLCCG1AFG: Safety logic control module compatible with GE DS200KLDBG1ABC—GE DS200KLDBG1ABC provides I/O signals, while GE DS200SLCCG1AFG executes safety interlock logic.

GE DS200PWRG1ABB: Dual redundant power supply for GE DS200KLDBG1ABC, ensuring stable 24V DC power input to avoid I/O signal loss due to power fluctuations.

GE 3500 Monitoring Module: Vibration and position monitoring module that collaborates with GE DS200KLDBG1ABC—GE 3500 sends alarm signals to GE DS200KLDBG1ABC for output to field alarms.

GE Mark V I/O Expansion Kit: Expansion accessory for GE DS200KLDBG1ABC, including terminal blocks and wiring harnesses to simplify module installation and wiring.

GE HEE-50 IP40 Enclosure: Optional protective enclosure for GE DS200KLDBG1ABC, upgrading protection to IP40 for use in dusty or humid environments (e.g., turbine halls).

GE DS200KLDFG1ABC: Digital input-only version of GE DS200KLDBG1ABC (32 input channels, no outputs), suitable for systems requiring only signal collection (e.g., status monitoring systems).

GE 9000 Signal Tester: Diagnostic tool for GE DS200KLDBG1ABC, used to test input/output channel functionality during commissioning or maintenance.

DS200KLDBG1ABC

Installation and Maintenance

Pre-installation preparation: First, confirm the GE Mark V control system firmware is v4.3+ to ensure compatibility with GE DS200KLDBG1ABC. Turn off the system power before installation to avoid short circuits. Use shielded twisted-pair cables for input/output wiring (24AWG–16AWG) and ground the cable shields at both ends to enhance anti-EMI performance. Connect GE DS200KLDBG1ABC to the GE DS200PWRG1ABB power supply, verify the input voltage is 24V DC (±10% tolerance), and check that the backplane bus connector is properly seated to ensure synchronous communication.

Maintenance recommendations: Conduct weekly visual inspections of GE DS200KLDBG1ABC’s LED indicators to confirm all channels are in normal status (green for active inputs/outputs, off for inactive, no red fault LEDs). Use the Mark V system’s remote diagnostic function monthly to monitor the module’s power consumption and temperature—if power consumption exceeds 20W or temperature exceeds 70°C, check for short-circuited outputs or blocked ventilation. Every 6 months, use the GE 9000 Signal Tester to verify input response time and output stability; retorque terminal connections to 0.8–1.0N·m to prevent loose wiring. Avoid hot-swapping GE DS200KLDBG1ABC during system operation to prevent damage to the module or backplane.

Product Guarantee

GE provides a 24-month quality guarantee for GE DS200KLDBG1ABC, covering manufacturing defects, component failures, and performance deviations under normal operating conditions (as specified in the product manual). During the guarantee period, if GE DS200KLDBG1ABC malfunctions due to quality issues, GE will provide a free replacement module and cover all international shipping costs for repair or exchange. Additionally, GE offers 24/7 global technical support for GE DS200KLDBG1ABC, including remote troubleshooting via phone or email, and on-site support (if required) for complex issues—ensuring customers resolve problems within 8 hours of contact. For long-term operations, GE provides customized maintenance training for GE DS200KLDBG1ABC, helping customers’ technicians master installation, diagnostics, and repair skills. This guarantee reflects GE’s commitment to product reliability and customer satisfaction.