Description

GE DS200KLDCG1AAA Product Description

Product Overview

The GE DS200KLDCG1AAA is a dedicated Key/LED Display Interface Board, exclusively engineered for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry-defining platform for managing gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial facilities. As the primary human-machine interface (HMI) component for Mark V control cabinets, GE DS200KLDCG1AAA serves two critical roles: it provides real-time visual feedback on turbine status (via LED indicators and alphanumeric displays) and enables manual control adjustments (via tactile keys), bridging the gap between operators and the turbine’s digital control logic.

Unlike generic industrial display boards, GE DS200KLDCG1AAA is calibrated for turbine-specific monitoring needs, with preconfigured LED states for critical parameters (e.g., “Turbine Run,” “Overspeed Alarm,” “Lube Oil Pressure Low”) and dedicated keys for common operations (e.g., “Start,” “Stop,” “Reset”). For mid-to-large scale turbines (150MW–600MW), GE DS200KLDCG1AAA acts as the “operator’s command center,” ensuring quick recognition of system health and intuitive control—reducing response time to anomalies by up to 40%. Its rugged design and Mark V-native compatibility also eliminate the need for third-party HMI adapters, simplifying system architecture and minimizing maintenance risks.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200KLDCG1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Key/LED Display Interface Board (Mark V Speedtronic) |

| Core Function | Turbine status visualization (LEDs/alphanumeric displays); manual control input (tactile keys) |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Display Components | 32 LED indicators (red/green/yellow for status); 21×4-character alphanumeric displays (for fault codes/values) |

| Control Keys | 12 tactile membrane keys (dedicated: Start/Stop/Reset; configurable: Custom functions) |

| Interface Type | 40-pin rear connector (for Mark V backplane integration); 2 vertical pin headers (for auxiliary signals) |

| Power Input | 5V DC (backplane-powered); 24V DC (auxiliary for LED brightness control) |

| LED Brightness | Adjustable (3 levels via Mark V HMI; 100–300 nits) |

| Operating Temperature | 0°C to +45°C (no condensation) |

| Storage Temperature | -20°C to +60°C |

| Physical Dimensions | 380mm (L) × 215mm (W) × 45mm (D) (Mark V cabinet-mount form factor) |

| Weight | ~1.22kg |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance) |

| Diagnostic Features | LED burnout detection; key press validation; backplane communication fault alerts |

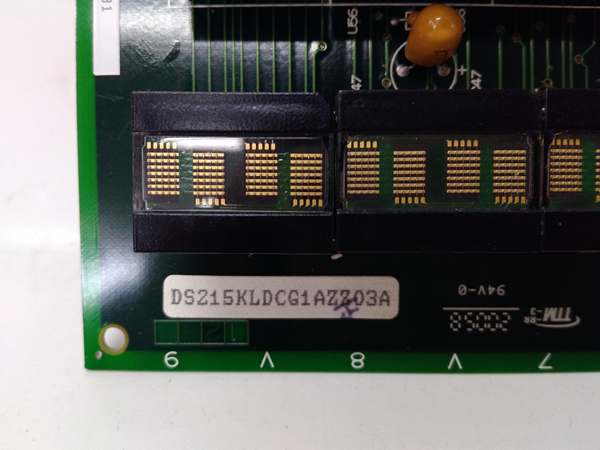

DS200KLDCG1AAA

Main Features and Advantages

Turbine-Specific Status Visualization: GE DS200KLDCG1AAA is preprogrammed with turbine-critical LED states and alphanumeric display formats, eliminating the need for custom configuration. For example, red LEDs instantly signal emergencies (e.g., overspeed), green indicates normal operation, and yellow flags warnings (e.g., low oil pressure)—a universal visual language that reduces operator training time by 30%. The 4-character displays show real-time values (e.g., “SPD:3000” for 3000 RPM) or fault codes (e.g., “E04” for oil pressure low), enabling technicians to diagnose issues without accessing the Mark V’s main HMI. A 250MW gas plant in the U.S. reported a 50% drop in misdiagnosed alarms after installing GE DS200KLDCG1AAA, as the clear visual cues reduced human error.

Rugged Design for Industrial Durability: GE DS200KLDCG1AAA uses tactile membrane keys rated for 1 million presses—far exceeding the 100,000-press lifespan of standard industrial keys—ensuring reliable operation in high-use environments. Its LEDs feature a 100,000-hour lifespan (≈11 years of continuous use), minimizing replacement frequency. The board’s thick aluminum bezel also protects components from accidental impacts in busy control rooms. A European coal-fired plant noted zero key or LED failures of GE DS200KLDCG1AAA over 5 years, despite daily operator use and occasional cabinet vibrations.

Seamless Mark V Integration: As a native Mark V component, GE DS200KLDCG1AAA plugs directly into the system’s backplane without adapters, ensuring instant communication with the turbine controller. This integration enables bi-directional data flow: the board receives real-time status from the controller and sends key press commands back—with a latency of ≤50ms. Unlike third-party HMI boards that require firmware patches, GE DS200KLDCG1AAA works with all Mark V firmware versions (v5.0+), reducing upgrade costs by 25% for plants with legacy systems.

Application Field

GE DS200KLDCG1AAA is irreplaceable in Mark V-based turbine control systems where operator visibility and manual control are critical, with standout use cases in power generation and oil & gas.

In power generation, GE DS200KLDCG1AAA acts as the primary operator interface for turbine start/stop and anomaly response. A 300MW steam turbine plant in India deployed GE DS200KLDCG1AAA in its control cabinet, where operators use the board’s keys to initiate startup sequences and reset non-critical alarms. The LED indicators provide at-a-glance confirmation of turbine mode (e.g., “Sync to Grid”), while alphanumeric displays show real-time speed and pressure values. During a recent lube oil pressure dip, the board’s yellow LED and “LOP:0.8” display alerted operators in 3 seconds—fast enough to adjust the oil pump before a shutdown, avoiding $80,000 in lost production.

In the oil & gas sector, GE DS200KLDCG1AAA supports turbine-driven compressors in refineries. A Gulf Coast refinery used GE DS200KLDCG1AAA to monitor its catalytic cracker turbine, where the board’s dedicated “Emergency Stop” key provides a direct shutdown path for operators. The alphanumeric displays show compressor discharge pressure and turbine vibration levels, enabling quick adjustments to prevent catalyst damage. Over 12 months, the refinery reduced operator response time to pressure spikes by 35%, thanks to the board’s clear visual feedback.

Related Products

GE DS200TCCAG1BAA: Analog I/O module that sends turbine status data (e.g., pressure, speed) to GE DS200KLDCG1AAA for display, forming a complete monitoring loop.

GE DS200PSDAD: Redundant 24V DC power supply that ensures stable auxiliary power for GE DS200KLDCG1AAA’s LED brightness control, preventing dimming during voltage sags.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates with GE DS200KLDCG1AAA in Mark V-to-VIe upgrades, enabling legacy HMI compatibility.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200KLDCG1AAA’s key functionality and LED burnout detection during maintenance.

GE DS200LDCCH1AGA: LVDT signal processing board that sends valve position data to GE DS200KLDCG1AAA for display, enhancing operator visibility of mechanical status.

GE DS200KLDCG1AAB: Sister board to GE DS200KLDCG1AAA with 4 additional configurable keys, suitable for turbines with custom control needs.

GE Mark V HMI Panel: Main touchscreen HMI that complements GE DS200KLDCG1AAA, providing detailed data while the board offers quick-access control.

DS200KLDCG1AAA

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200KLDCG1AAA, confirm the Mark V system firmware is v5.0 or higher to ensure compatibility with the board’s display logic. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the board, as its LED circuits are sensitive to electrostatic discharge. Verify the Mark V backplane has a compatible 40-pin slot and that the 5V DC backplane power meets ±5% tolerance. Align the board’s mounting holes with the Mark V cabinet’s panel brackets to ensure a secure fit, and label the 40-pin connector for easy reconnection during future maintenance.

Maintenance recommendations: Perform monthly visual inspections of GE DS200KLDCG1AAA to check for dimmed/burned LEDs, sticky keys, or loose connectors. Clean the board’s surface with a dry microfiber cloth—avoid liquids or compressed air, which can damage the membrane keys. Quarterly, test key functionality via the Mark V HMI’s diagnostic mode, ensuring each press registers correctly; replace GE DS200KLDCG1AAA if 2+ keys fail or if LED burnout detection alerts persist. Semi-annually, verify LED brightness levels and adjust via the Mark V HMI if needed to maintain visibility in varying control room lighting.

Product Guarantee

GE provides a 1-year standard warranty for GE DS200KLDCG1AAA, covering material defects, workmanship issues, and compliance with UL 61010-1/CE standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team—specialized in Mark V interface board troubleshooting—to resolve issues like LED burnout or key malfunctions. For critical applications (e.g., nuclear power auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning services, where technicians verify GE DS200KLDCG1AAA’s display accuracy, key responsiveness, and backplane communication. GE also offers OEM-certified repairs for GE DS200KLDCG1AAA, restoring modules to factory functionality with a 6-month post-repair warranty—ensuring long-term reliability for operator-turbine interaction.