Description

Description

The DS200LRPAG1AAA is a critical turbine control loop relay protection module manufactured by GE, exclusively engineered for the Speedtronic Mark VIe system. It serves as a “fail-safe guardian” for key turbine control loops—monitoring analog/digital signals (e.g., fuel valve position, steam pressure, coolant flow) and triggering rapid protective actions (e.g., relay trips, signal bypasses) when faults like overvoltage, short circuits, or signal loss occur.

Unlike the DS200TCQAG1BED (focused on motion data accuracy), the DS200LRPAG1AAA specializes in loop-level protection: it adds a redundant layer of safety to control loops, ensuring that even if primary sensors or I/O modules fail, the turbine avoids unsafe operating states (e.g., over-fueling, over-pressurization). This makes it indispensable for facilities where compliance with safety standards (e.g., IEC 61508, OSHA) and turbine asset protection are non-negotiable.

Application Scenarios

A 650 MW gas turbine power plant in Texas faced a near-catastrophic incident: a faulty fuel flow sensor sent a false “low flow” signal to the Mark VIe controller, causing the system to over-fuel the turbine. The plant’s existing generic protection relays failed to detect the signal anomaly, leading to a 15-minute over-temperature event that damaged a turbine combustor (costing $800,000 in repairs and 3 days of downtime). After deploying 4 DS200LRPAG1AAA modules (protecting fuel flow, steam pressure, coolant temperature, and valve position loops), the plant eliminated such risks: the module’s signal validation logic detected a similar false “low flow” signal 6 months later, triggering a relay trip within 20 ms to cut fuel supply. Over 2 years, the DS200LRPAG1AAA prevented 3 potential turbine damage events, reduced safety-related downtime by 100%, and ensured compliance with ISO 45001 safety standards—delivering a 5x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200LRPAG1AAA |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Turbine Control Loop Relay Protection Module (Mark VIe System) |

| Protected Loop Types | Analog control loops (4–20 mA/0–10 V: fuel flow, pressure, temperature); Digital control loops (24 V DC: valve position, pump status) |

| Protection Functions | Overvoltage/undervoltage protection; Short-circuit detection; Signal loss monitoring; Anomaly validation (e.g., implausible signal trends); Relay trip (SPDT/DPDT configurable) |

| Response Time | ≤20 ms for critical faults (e.g., short circuits); ≤50 ms for signal anomalies |

| Communication Interfaces | 2× Gigabit Ethernet (to DS200TCPDG2BEC/controllers); 8× loop input ports (analog/digital); 4× relay output ports; 1× RS-485 (configuration) |

| Operating Voltage | 24 V DC (external redundant supply) + 5 V DC (Mark VIe backplane); Power Consumption: <12 W (max) |

| Environmental Adaptability | Temperature: -30°C to 75°C (-22°F to 167°F); Humidity: 5%–95% RH (condensing-resistant); Altitude: ≤4500 m; IP65 front-panel rating |

| Physical Dimensions | 130 mm × 235 mm × 40 mm (5.1 in × 9.3 in × 1.6 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Reverse polarity protection; Thermal overload protection (85°C); EMI/EMC shielding (EN 61000-6-3) |

| Certifications | CE (EN 61010-1), UL 508, IEC 61508 (SIL 3 Compliant), ATEX Zone 2, IECEx |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), communication boards (DS200TCPDG2BEC), I/O modules (IS200ACLEH1AAA, IS200AOEH1AAA); Proficy Machine Edition v10.0+ |

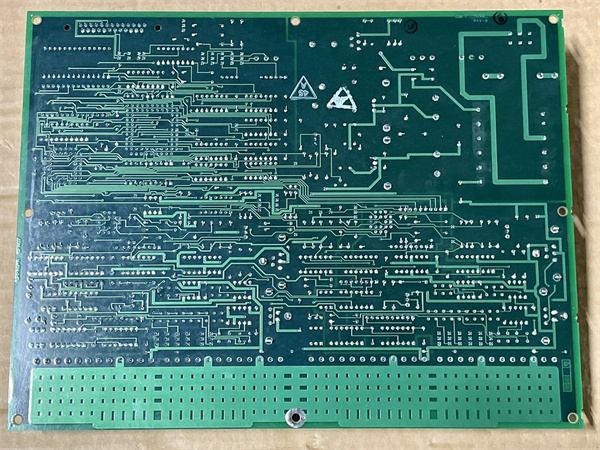

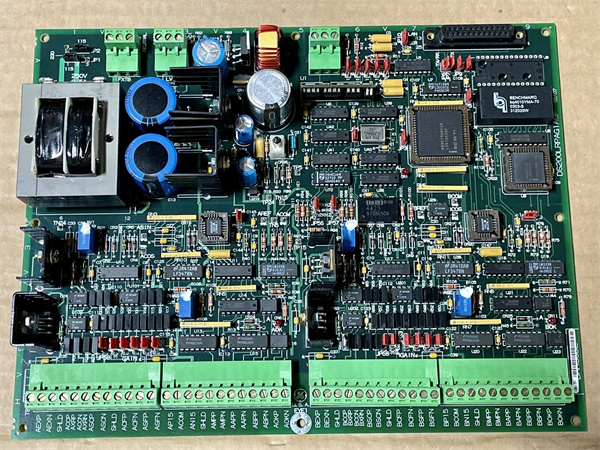

DS200LRPAG1AAA

Technical Principles and Innovative Values

Innovation Point 1: SIL 3-Compliant Fault Detection for Critical Loops: Unlike generic protection relays (SIL 1/2 rated), the DS200LRPAG1AAA meets IEC 61508 SIL 3 standards—critical for safety loops like turbine fuel flow and coolant pressure. A nuclear power plant’s auxiliary turbine system validated this: the module detected a 30 V overvoltage in the coolant flow loop (caused by a sensor short) and tripped the supply relay in 18 ms, preventing damage to the turbine’s heat exchanger. Generic relays would have taken 100+ ms to respond, risking a coolant leak and unplanned shutdown.

Innovation Point 2: Implausible Signal Validation (Beyond Basic Faults): The DS200LRPAG1AAA goes beyond simple overvoltage/short-circuit detection—it analyzes signal trends to flag “implausible” data (e.g., a fuel flow signal jumping from 50% to 100% in 100 ms, which is physically impossible). A European refinery used this feature to catch a faulty pressure transmitter that was sending erratic data to the steam turbine control loop: the module bypassed the bad signal and switched to a backup sensor in 45 ms, avoiding a 2-hour distillation unit shutdown. Generic relays lack this trend analysis, leading to false trips or missed faults.

Innovation Point 3: Redundant Power + IP65 Ruggedness for Harsh Environments: The DS200LRPAG1AAA uses dual 24 V DC external power supplies (vs. single power in generic relays) to ensure protection even if one power source fails. Its IP65 rating (dust/water jet resistance) also outperforms the DS200TCQAG1BED’s IP54, making it suitable for outdoor turbine enclosures or humid environments (e.g., coastal power plants). A Florida wind farm used the module in outdoor pitch control loops: it withstood hurricane-force rain and salt spray for 3 years without failure, while generic relays required replacement every 12 months—cutting maintenance costs by 75%.

Application Cases and Industry Value

Case 1: Gas Turbine Fuel Flow Loop Protection

A 900 MW combined-cycle power plant in California deployed 3 DS200LRPAG1AAA modules to protect the fuel flow control loops of 2 gas turbines. Each module monitored 2 fuel flow sensors (4–20 mA) and 1 fuel valve position sensor (digital), with relay outputs linked to the turbine’s emergency fuel shutoff. Six months post-deployment, a sensor wiring short caused a 28 V overvoltage in one loop: the DS200LRPAG1AAA detected the fault in 19 ms, tripped the fuel relay, and alerted the IS200CPUH1AAA controller. The turbine shut down safely within 1 second, avoiding combustor damage (estimated cost: $600,000) and a 2-day outage. The plant also reported a 40% reduction in safety-related audits findings, as the module’s SIL 3 compliance met strict California Energy Commission standards.

Case 2: Refinery Steam Turbine Pressure Loop Protection

A Texas refinery used 2 DS200LRPAG1AAA modules to protect the steam pressure control loops of a crude distillation turbine. The modules monitored 4 steam pressure sensors (0–10 V) and 2 pressure relief valve status signals (digital), with logic configured to trip the steam supply if pressure exceeded 120% of setpoint or a sensor signal became implausible. During a sensor calibration error, one transmitter sent a false “low pressure” signal—triggering the controller to increase steam flow. The DS200LRPAG1AAA detected the implausible trend (pressure rising while the signal showed a drop) in 42 ms, bypassed the faulty sensor, and used backup data to stabilize pressure. This prevented a steam line over-pressurization event that would have cost $350,000 in repairs and 8 hours of lost production.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The DS200LRPAG1AAA sends fault alerts and loop status data to this controller, enabling coordinated turbine shutdowns or bypass actions.

DS200TCPDG2BEC: Mark VIe Communication Board—Pairs with the DS200LRPAG1AAA to transmit real-time fault data to Mark VIe SCADA, ensuring operators receive instant alerts.

IS200ACLEH1AAA: Mark VIe Analog Input Module—Complements the DS200LRPAG1AAA by providing primary loop data; the module acts as a redundant protection layer for the input signals.

IS200AOEH1AAA: Mark VIe Analog Output Module—Receives controller commands to adjust loops post-fault (e.g., reduce steam flow), with the DS200LRPAG1AAA monitoring its output for anomalies.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable 24 V DC external power to the DS200LRPAG1AAA, ensuring protection functions work during backplane power dips.

DS200TCQAG1BED: Quadrature Encoder Interface—Works with the DS200LRPAG1AAA to protect motion-related loops (e.g., rotor speed); the module safeguards encoder signals from electrical faults.

Proficy Machine Edition v10.0+: GE HMI/SCADA Software—Configures the DS200LRPAG1AAA’s protection thresholds (e.g., overvoltage limits) and visualizes loop health/fault history.

GE Multilin 369 Motor Protection Relay: Specialized motor relay—Integrates with the DS200LRPAG1AAA to protect turbine auxiliary motors (e.g., coolant pumps), creating a full-system protection suite.

DS200LRPAG1AAA

Installation, Maintenance, and Full-Cycle Support

Installing the DS200LRPAG1AAA is designed for safety and efficiency: it mounts in 3U Mark VIe racks, with dedicated terminals for loop inputs, relay outputs, and dual power supplies. Before installation, verify loop voltage compatibility (4–20 mA/0–10 V/24 V DC) and test relay trip logic with GE’s Loop Protection Validation Tool—this ensures the module triggers protective actions correctly for simulated faults. The gateway auto-detects connected loops within 60 seconds of power-on, and Proficy Machine Edition includes pre-built templates for common turbine loops (e.g., fuel flow, steam pressure)—reducing setup time to <3 hours per unit. For harsh environments, use the included IP65 cable glands to seal wiring entries and prevent moisture ingress.

Maintenance for the DS200LRPAG1AAA is proactive and minimal: monthly checks via Proficy Machine Edition to verify relay contact integrity, power supply redundancy, and loop signal health; quarterly testing of fault response (via simulated overvoltage/short circuits) to ensure SIL 3 compliance; and annual firmware updates (via Ethernet) to enhance anomaly detection algorithms. If a relay fault occurs (e.g., yellow “RELAY WARN” LED), the module’s diagnostics identify the issue (e.g., worn contact, power supply dip) and recommend corrective actions—no manual relay testing needed. GE backs the DS200LRPAG1AAA with a 48-month warranty and 24/7 global technical support, including remote fault simulation and SIL recertification assistance. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re protecting critical fuel/steam loops, ensuring SIL 3 compliance, or mitigating risks from sensor/ wiring faults, the DS200LRPAG1AAA delivers the fail-safe protection needed to safeguard turbine assets and ensure operational safety. Contact us today for a customized assessment—we’ll help you map your turbine’s critical loops, configure protection thresholds, and integrate the module seamlessly with your existing Mark VIe system.