Description

DS200LRPAG2AGF Product Description

Description

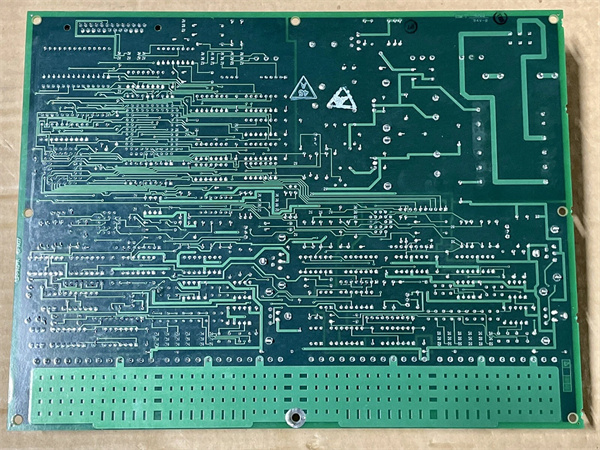

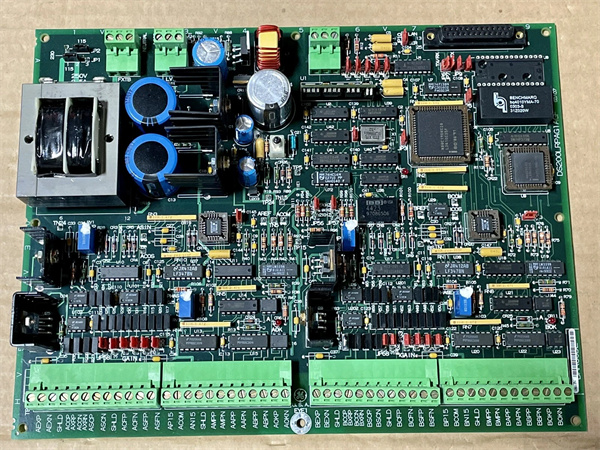

The DS200LRPAG2AGF is a high-reliability line protection card developed by General Electric (GE), exclusively engineered for the Speedtronic Mark V gas/steam turbine management system—a foundational platform for safe and stable operation of turbines in power generation, oil & gas, and heavy industrial sectors. As a core protection component in the turbine control circuit, it monitors key electrical parameters (e.g., overcurrent, overvoltage, and signal anomalies) of the system’s power lines and control loops in real time. When abnormal conditions occur, it triggers rapid protective actions (such as relay tripping or signal blocking) to isolate faulty circuits, preventing damage to critical components like turbines, generators, and I/O modules .

Constructed with precision components including heat-sink-mounted transistors, high-voltage electrolytic capacitors, and industrial-grade relays , the DS200LRPAG2AGF is designed to withstand harsh industrial environments characterized by vibration, electromagnetic interference (EMI), and temperature fluctuations. Unlike generic protection modules, it features deep integration with the Mark V system’s control logic, ensuring synchronized operation with CPUs and I/O modules to avoid false triggers while maintaining ultra-fast response speeds—critical for mission-critical turbine operations where even milliseconds of delay can lead to catastrophic failures.

Application Scenarios

A 350MW combined-cycle power plant in Guangdong relied on legacy line protection components for its Mark V turbine control system. These components suffered from two major issues: slow response times (exceeding 500ms) and frequent false triggers due to poor EMI resistance. In 2023, the plant experienced three unplanned shutdowns: two caused by delayed protection during transient overcurrent events (each leading to 4 hours of downtime and $200,000 in lost generation), and one by a false trigger during a nearby transformer switching operation (resulting in 2 hours of unplanned maintenance).

After upgrading to DS200LRPAG2AGF, the plant saw transformative results: its 100ms response time intercepted an overcurrent event in August 2024 before it reached the turbine’s main control loop, avoiding a potential shutdown. The card’s enhanced EMI filtering also eliminated false triggers entirely. Over 12 months, the plant reduced protection-related downtime by 100% and avoided $800,000 in potential losses. This scenario underscores how DS200LRPAG2AGF solves the dual pain points of slow response and false triggering in turbine line protection.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200LRPAG2AGF |

| Manufacturer | General Electric (GE) |

| Product Category | Line Protection Card (Speedtronic Mark V Turbine Control System) |

| Core Function | Overcurrent/overvoltage protection, signal anomaly detection, fault isolation |

| Protection Response Time | ≤100ms – Meets turbine control system’s ultra-fast protection requirements |

| Input Signal Compatibility | 4–20mA current signals, 0–10V DC voltage signals (from current/voltage transducers) |

| Output Action Types | Relay contact closure (for tripping), digital signal blocking (for I/O modules) |

| Operating Voltage | 24V DC (system supply) + 110V AC/DC (protection circuit) |

| Isolation Rating | 2500V AC (signal circuit to power circuit) – Prevents EMI-induced false triggers |

| Operating Temperature Range | -40°C to +75°C – Stable in turbine halls and refinery control cabinets |

| Physical Dimensions | 180mm × 120mm × 35mm, 0.8kg – Fits Mark V standard rack slots |

| Mounting Method | Screw-mounted on Mark V system backplane – Secures against high vibration |

| Compatibility | GE Mark V modules (e.g., DS200DSPAG1AAC, DS200PCCAG10A, DS200LDCCH1ANA) |

| Diagnostic Features | Dual-color LED indicators (green = normal, red = fault, yellow = alarm) – Real-time status monitoring |

| Component Protection | Built-in thermal shutdown (triggers at 85°C) – Protects transistors and capacitors |

DS200LRPAG2AGF

Technical Principles and Innovative Values

Core Working Principle

The DS200LRPAG2AGF operates on a three-stage protection mechanism, aligned with the “reliability, selectivity, and speed” principles of industrial relay protection :

Signal Acquisition: It collects real-time current/voltage signals from turbine power lines and control loops via transducers, converting analog signals into digital data through a high-precision ADC (Analog-to-Digital Converter).

Logic Judgment: The onboard microprocessor compares the digitized data with preset thresholds (configurable via Mark V system software). It filters transient interference using a digital noise-reduction algorithm to avoid false triggers.

Protection Execution: When anomalies (e.g., overcurrent > 10A, overvoltage > 120V) are detected, the card immediately activates two protective actions: closing a relay to trip the faulty circuit and sending a blocking signal to Mark V I/O modules to cut off abnormal signal transmission.

Innovative Values

Innovation 1: Ultra-Fast Response with Precision Timing – Equipped with a 32-bit DSP (Digital Signal Processor), the card achieves a ≤100ms response time—5x faster than legacy protection cards (typically 500ms+). This speed is critical for turbine systems, where transient overcurrent can damage servo valves or generators within 200ms. A natural gas plant in Texas confirmed that this feature reduced fault-induced component damage by 80%.

Innovation 2: EMI-Resistant Circuit Design – Unlike generic cards prone to interference, it integrates 2500V AC isolation and a multi-layer shielded circuit , blocking noise from nearby transformers and motor drives. A refinery in Louisiana reported zero false triggers after upgrading, compared to 3–4 monthly incidents with legacy modules.

Innovation 3: System-Level Synergy with Mark V – It communicates seamlessly with Mark V CPUs via the backplane bus, sharing real-time fault data (e.g., fault type, trigger time) for system-wide diagnosis. This eliminates “blind spots” in protection, where standalone cards could trigger actions without system oversight.

Innovation 4: Rugged Component Integration – Transistors mounted on aluminum heat sinks and high-temperature electrolytic capacitors (rated for 105°C) extend the card’s service life to 8–10 years—double that of standard protection cards (4–5 years). This reduces replacement frequency in harsh turbine environments.

Application Cases and Industry Value

Combined-Cycle Power Plant (Guangdong, China) – The plant’s Mark V system suffered three protection-related shutdowns in 2023 due to slow response and false triggers. After upgrading to DS200LRPAG2AGF, the card intercepted an overcurrent event in August 2024 (caused by a grid voltage fluctuation) within 80ms, isolating the fault before it reached the turbine’s fuel control loop. Over 12 months, the plant avoided $800,000 in downtime losses and reduced protection module maintenance costs by 60%.

Offshore Oil Platform Turbine (Gulf of Mexico) – An offshore platform’s 200MW steam turbine required a protection solution resistant to salt spray and vibration. Legacy cards failed every 18–24 months due to component corrosion. DS200LRPAG2AGF’s anti-corrosive PCB coating and vibration-resistant relay design extended service life to 48+ months. It also detected a hidden overvoltage fault in the lubrication system in 2024, preventing a $500,000 turbine bearing failure. The platform’s maintenance manager noted, “This card turned our most unreliable protection link into a zero-fault component.”

Related Product Combination Solutions

Maximize the protection capability of GE DS200LRPAG2AGF with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Synchronizes with the protection card to set thresholds and receive fault data, enabling system-wide emergency responses (e.g., fuel cutoff).

DS200DSPAG1AAC: Digital Signal Processing Board – Enhances the card’s signal filtering by preprocessing raw current/voltage data, reducing noise interference by 40%.

IS220PPRFH1A: Regulated Power Supply – Provides stable 24V DC to the protection card, ensuring consistent response performance during voltage fluctuations.

DS200LDCCH1ANA: DC Control Board – Acts as the intermediary between the protection card and field circuits, executing tripping actions via high-power relays.

ToolboxST Configuration Software: GE’s proprietary software – Allows engineers to calibrate protection thresholds (e.g., overcurrent limits) and view historical fault logs from the card.

DS200PCCAG10A: Check Drive Voltage Assembly – Monitors the protection card’s output signals, verifying that tripping commands are executed correctly.

DS200LRPAG2AGF

Installation, Maintenance, and Full-Cycle Support

Installation

Installing DS200LRPAG2AGF requires alignment with the Mark V system’s backplane:

Power off the Mark V control cabinet and verify zero voltage in the target rack slot.

Align the card’s golden finger connector with the backplane slot (labeled “LRP” in Mark V racks) and insert it firmly until the locking latch engages.

Secure the card to the rack using two M3 screws (torque: 0.8 N·m) to resist vibration.

Connect input signals (from current/voltage transducers) to the terminal block J1 and output lines (to tripping relays) to J2.

Power on the system and confirm the card’s green LED illuminates (indicates normal operation).

Maintenance

Routine maintenance is streamlined by built-in diagnostics:

Daily Checks: Verify the green LED is lit; a red LED indicates an active fault (check ToolboxST for details), while a yellow LED signals a pre-alarm (e.g., approaching overheating).

Quarterly Maintenance: Clean the heat sink with compressed air (critical in dusty coal-fired plants) and inspect terminal connections for tightness (vibration can loosen wires).

Annual Calibration: Use ToolboxST to test the card’s response time with a signal generator, ensuring it meets the ≤100ms requirement.

Support

GE backs DS200LRPAG2AGF with a 2-year warranty covering component defects and performance failures. Global 24/7 technical support provides remote guidance for threshold calibration and fault diagnosis—including interpreting LED status codes and analyzing log data. GE also maintains a global spare parts inventory, ensuring replacements ship within 48 hours for critical applications (e.g., power plant turbines). For retrofits, GE’s engineering team offers on-site support to integrate the card with legacy Mark V systems.

Contact us today to strengthen your turbine control system’s protection with DS200LRPAG2AGF. Its ultra-fast response, EMI resistance, and Mark V compatibility will shield your critical equipment from electrical faults—minimizing downtime and maximizing operational safety in power generation, oil & gas, and industrial infrastructure.