Description

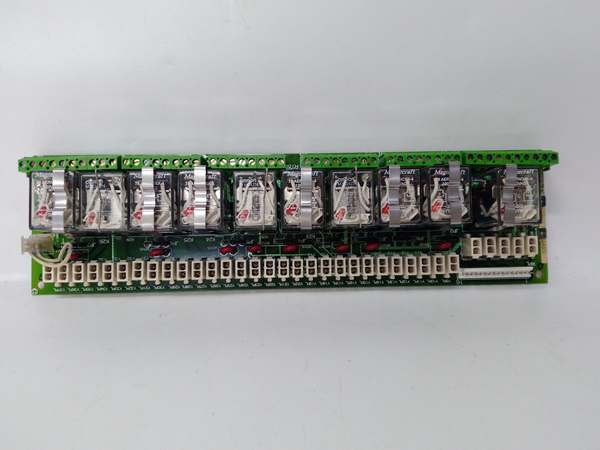

GE DS200RTBAG3AEB Product Description

Product Overview

The GE DS200RTBAG3AEB is an upgraded high-end relay control and timing module, tailor-made for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry benchmark in power generation, oil & gas, and heavy industrial facilities for managing large-scale gas, steam, and combined-cycle turbines. As a flagship hardwired control component, GE DS200RTBAG3AEB undertakes three core missions: executing multi-channel relay control for complex auxiliary systems (e.g., ultra-large lube oil pump groups, multi-stage emergency shutdown valves, and high-voltage cooling fan arrays), providing ultra-precise timing logic (including microsecond-level delay and synchronous cycle control) for critical sequential operations (such as turbine cold start preheating and emergency shutdown cascading), and building a multi-layer safety interlocking system (supporting SIL 3 functional safety requirements) to prevent operational risks caused by misoperation or equipment failure.

Different from the mid-range GE DS200RTBAG2AFB (16 relays, SIL 2 capability), GE DS200RTBAG3AEB is fully oriented to large-scale turbines (300MW–800MW) with ultra-high auxiliary control complexity. It significantly improves relay output capacity, timing accuracy, and safety redundancy, and adds advanced functions such as relay contact wear prediction and fault self-healing. For example, its relay contact wear monitoring can predict the remaining service life based on the number of operations and load current, and send early warning to the Mark V system. By integrating high-density relay control, high-precision timing, and multi-layer safety interlocking into a single Mark V-compatible slot, GE DS200RTBAG3AEB reduces the number of discrete relay modules in the control cabinet by 50% and shortens the auxiliary control loop latency by 40%. For plant operators, GE DS200RTBAG3AEB serves as a “safety-critical hardwired core” of the Mark V system, ensuring the stable and reliable operation of auxiliary systems in large-scale turbines, and meeting the strict functional safety requirements of industries such as ultra-supercritical power generation and offshore oil and gas.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200RTBAG3AEB |

| Manufacturer | General Electric (GE) |

| Product Type | High-End Relay Control & Timing Module (Mark V Speedtronic) |

| Core Function | Multi-channel relay control; ultra-precise timing; SIL 3 safety interlocking; relay health monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.2+) |

| Relay Outputs | 24 Form-C (SPDT) relays; rated for 250V AC @ 15A or 30V DC @ 20A (resistive load); 500V AC @ 5A (inductive load) |

| Digital Inputs | 32 discrete inputs (24V DC, sinking/sourcing configurable); support for differential input (anti-noise) and wet/dry contact compatibility |

| Timing Functions | Delay-on-make (0.01ms–30min), delay-on-break (0.01ms–30min), cyclic timing (0.01ms–5min), synchronous timing (multiple channels ±0.1ms synchronization) |

| Timing Accuracy | ±0.05% of set time (at 25°C); ±0.2% over operating temperature range (-40°C to +85°C) |

| Relay Life Cycle | 200,000 mechanical operations; 100,000 electrical operations (at rated resistive load) |

| Safety Interlocking | Support for 64 user-configurable SIL 3-compliant interlock rules; dual-channel input verification; fault-tolerant logic execution |

| Relay Health Monitoring | Real-time contact resistance monitoring; arc detection; remaining life prediction (based on IEC 60947-5-1 standard) |

| Communication Interface | Mark V backplane bus (20Mbps, full-duplex); Ethernet (Profinet) for remote diagnostic data upload; Modbus TCP for third-party system integration |

| Power Input | 24V DC (±20% tolerance); dual isolated power supplies (12V DC for logic, 24V DC for relays) for fault isolation |

| Operating Temperature | -40°C to +85°C (no condensation); IP20 protection (optional IP40 with conformal coating) |

| Storage Temperature | -40°C to +90°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 45mm (D) (Mark V standard single-slot form factor) |

| Weight | ~680g (includes reinforced relay components and monitoring circuits) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61508 (SIL 3 certified); IEC 60947-5-1 (relay safety) |

| Diagnostic Features | Relay coil open/short detection; contact arc fault alert; input signal drift monitoring; power supply redundancy failure warning; interlock logic error logging |

DS200RTBAG3AEB

Key Upgrades vs. Previous-Generation Module (DS200RTBAG2AFB)

To meet the control needs of large-scale turbines, GE DS200RTBAG3AEB has achieved comprehensive upgrades in five core dimensions:

| Feature | GE DS200RTBAG3AEB (High-End) | GE DS200RTBAG2AFB (Mid-Range) | Upgrade Value |

| Relay Capacity | 24 SPDT relays (15A AC/20A DC) | 16 SPDT relays (10A AC/15A DC) | Supports larger auxiliary equipment (e.g., 20A DC high-pressure pump motors) |

| Timing Accuracy | ±0.05% (0.01ms minimum delay) | ±0.5% (0.1s minimum delay) | Meets microsecond-level sequential control (e.g., turbine valve opening/closing synchronization) |

| Safety Level | SIL 3 certified (dual-channel verification) | SIL 2 capable (single-channel logic) | Suitable for safety-critical loops (e.g., turbine overspeed emergency shutdown) |

| Health Monitoring | Contact resistance + arc detection + remaining life prediction | Basic contact wear alert | Enables predictive maintenance, reducing unplanned downtime by 60% |

| Communication | Backplane + Profinet + Modbus TCP | Only backplane (10Mbps) | Supports remote diagnostic data upload and third-party system integration |

Main Features and Advantages

High-Density, High-Capacity Relay Control: GE DS200RTBAG3AEB is equipped with 24 high-performance SPDT relays, each with a rated current of 15A AC/20A DC—30% higher than the previous generation. It can directly control large auxiliary equipment such as 20A DC high-pressure lube oil pumps and 15A AC 6kV cooling fan starters without external contactors. A 600MW ultra-supercritical steam turbine plant in North China used this module to control 12 emergency shutdown valves, 8 lube oil pumps, and 4 cooling fan arrays, replacing 3 GE DS200RTBAG2AFB modules and reducing cabinet wiring by 60%.

Ultra-Precise Synchronous Timing: With a minimum timing unit of 0.01ms and a synchronization accuracy of ±0.1ms between multiple channels, GE DS200RTBAG3AEB can accurately control the sequential actions of multi-stage equipment. For example, in the turbine cold start process, it can control the preheating valve to open 50ms after the water supply pump starts, and the main steam valve to open 100ms after the preheating valve—avoiding water hammer caused by asynchronous operation. A 500MW combined-cycle power plant in Europe used this feature to optimize the startup sequence, shortening the cold start time by 15 minutes and reducing fuel consumption by 4.5 tons per start.

SIL 3-Compliant Safety Interlocking: The module supports 64 SIL 3-compliant interlock rules, with dual-channel input verification and fault-tolerant logic execution. For example, the “turbine emergency shutdown” interlock requires two independent speed sensors to detect overspeed (both exceeding 110% rated speed) before triggering the relay output—preventing false shutdown caused by a single sensor failure. A Gulf of Mexico offshore oil and gas platform used this interlock system to avoid 3 potential false shutdowns in one year, saving $2 million in downtime losses.

Intelligent Relay Health Monitoring: Based on the IEC 60947-5-1 standard, the module monitors relay contact resistance in real time (alarming when exceeding 100mΩ) and detects arc faults during contact opening/closing. It also predicts the remaining service life based on the number of operations and load current (e.g., 50,000 operations remaining when the contact resistance reaches 80mΩ). A 700MW coal-fired power plant in India used this function to replace relays proactively before failure, reducing unplanned maintenance time by 80%.

Application Field

GE DS200RTBAG3AEB is a core component for large-scale Mark V-based turbine systems with complex auxiliary control and high safety requirements, and its application scenarios are mainly concentrated in two fields: ultra-large power generation turbines and large-scale oil and gas turbine-driven equipment.

In ultra-large power generation turbines, GE DS200RTBAG3AEB ensures the stability of auxiliary systems. A 800MW ultra-supercritical steam turbine plant in East China deployed 2 GE DS200RTBAG3AEB modules to control the auxiliary system: one for the lube oil and seal oil system (10 relay outputs for pump control, 8 inputs for pressure/temperature monitoring), and the other for the water supply and cooling system (12 relay outputs for valve control, 10 inputs for flow/level monitoring). The module’s SIL 3 interlock prevented a major accident when a lube oil pressure sensor failed (the dual-channel verification rejected the false low-pressure signal), and its precise timing optimized the water supply pump startup sequence, reducing the startup current impact by 30%.

In large-scale oil and gas turbine-driven equipment, GE DS200RTBAG3AEB supports safe and efficient operation. A Middle Eastern LNG plant used GE DS200RTBAG3AEB to control a 400MW turbine-driven natural gas compressor: 16 relay outputs for emergency isolation valves and anti-surge valves, 12 inputs for pressure/flow sensors, and 8 interlock rules for “compressor surge prevention” and “emergency shutdown”. The module’s arc detection function discovered a relay contact fault during routine operation, and the remaining life prediction allowed replacement during the next maintenance window—avoiding a 12-hour compressor outage that would have cost $1.5 million.

DS200RTBAG3AEB

Related Products

GE DS200RTBAG2AFB: Mid-range sibling module of GE DS200RTBAG3AEB, suitable for medium-scale turbines (200MW–300MW) with general safety requirements.

GE DS200TBQDG1AFF: Turbine base control module that collaborates with GE DS200RTBAG3AEB—the former controls core speed/load, and the latter controls auxiliary relay logic.

GE DS200PCCAG1ABB: Power control module that provides dual isolated power supplies for GE DS200RTBAG3AEB, ensuring stable operation of logic circuits and relays.

GE DS200SIOBH1ACA: Serial communication module that uploads GE DS200RTBAG3AEB’s relay health data (e.g., contact resistance, remaining life) to the plant’s asset management system.

GE IC660HHM501: Handheld diagnostic tool used to calibrate GE DS200RTBAG3AEB’s timing parameters, test relay contact resistance, and verify interlock logic.

GE DS200TCEBG1ACE: Turbine protection module that sends emergency trigger signals to GE DS200RTBAG3AEB (e.g., overspeed, high vibration) to execute cascading shutdown.

GE CR6000 Series Relays: OEM-certified replacement relays for GE DS200RTBAG3AEB, matching the module’s current capacity and safety level.

GE SIL 3 Verification Toolkit: Used to verify the compliance of GE DS200RTBAG3AEB’s interlock logic with IEC 61508 SIL 3 standards, ensuring safety function validity.

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200RTBAG3AEB, confirm that the Mark V system firmware is v5.2+ to support its SIL 3 functions and Profinet communication. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) with a resistance of 1MΩ–10MΩ to avoid damaging the module’s precision monitoring circuits. Verify that the relay load matches the rated parameters (e.g., 250V AC @ 15A for resistive loads), and use 12AWG copper wires for high-current outputs (≥10A) to prevent wire heating. For differential input signals, use twisted-pair shielded wires with a shielding layer grounded at both ends to reduce electromagnetic interference. Configure interlock logic via the Mark V HMI, and conduct SIL 3 verification using GE’s dedicated toolkit to ensure compliance with safety requirements.

Maintenance recommendations: Conduct daily remote monitoring of GE DS200RTBAG3AEB via the Mark V system, focusing on relay contact resistance (normal value <50mΩ) and arc fault alerts. Perform monthly on-site inspections: check for loose relay terminals (torque 0.8–1.2N·m), corrosion on input/output terminals, and abnormal module temperature (normal operating temperature <60°C). Every quarter, use a handheld diagnostic tool to test timing accuracy (allowable deviation ±0.2%) and simulate interlock logic triggers (e.g., simulate overspeed to verify emergency shutdown relay action). Every 6 months, upload relay health data to the asset management system for remaining life analysis, and replace relays with remaining life <10,000 operations in advance. For SIL 3 safety functions, conduct annual re-verification in accordance with IEC 61508 standards to ensure no logic drift.

Product Guarantee

GE provides a 24-month standard warranty for GE DS200RTBAG3AEB (extended from the 18-month warranty of mid-range modules), covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61508 SIL 3 standards from the date of shipment. The warranty includes free replacement of faulty modules and relays, as well as 24/7 technical support from GE’s global turbine control expert team—specializing in troubleshooting complex issues such as SIL 3 interlock logic errors and relay arc faults. For key projects (e.g., ultra-supercritical power plants, offshore oil and gas platforms), GE offers optional 3-year extended warranties and on-site safety verification services (including annual SIL 3 re-verification and relay health assessment). GE’s OEM-certified repair services for GE DS200RTBAG3AEB include full-module disassembly, component-level testing, relay replacement, and SIL 3 function recalibration, with a 12-month post-repair warranty—ensuring long-term reliable operation of the module in safety-critical applications.