Description

DS200RTBAG3AFB Product Description

Description

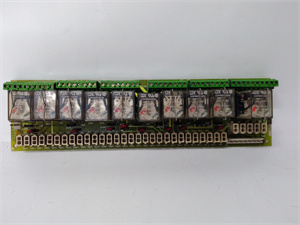

The DS200RTBAG3AFB is a high-density, rugged rack terminal board developed by General Electric (GE), exclusively engineered for seamless integration with the Speedtronic Mark VI turbine control system—the industry standard for safe, reliable operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It acts as the “critical signal bridge” between field devices (e.g., pressure sensors, limit switches, valve actuators) and Mark VI I/O modules, CPUs, and communication cards, organizing signal termination while filtering electrical noise and protecting against voltage surges.

Unlike generic terminal boards that struggle with turbine-specific harsh conditions (vibration, EMI, temperature swings), DS200RTBAG3AFB features an ultra-dense terminal layout, color-coded signal grouping, and reinforced isolation—designed to cut wiring errors, minimize signal degradation, and withstand the rigors of industrial control cabinets. Its plug-and-play compatibility with Mark VI hardware also slashes installation time, a key advantage for retrofits or emergency maintenance.

Application Scenarios

A 500MW coal-fired power plant in Ohio faced recurring signal-related disruptions in its Mark VI turbine control system: its legacy terminal boards used unlabeled, low-density terminals, leading to 4–6 monthly “false signal loss” alarms (caused by miswired or loose connections). Each alarm required 2.2 hours of manual troubleshooting (using a multimeter to trace wires), costing $132,000 in annual lost generation. The plant also struggled with EMI from nearby 6kV motors, which corrupted 2–3% of analog sensor data (e.g., bearing temperature readings), leading to unnecessary maintenance checks and inefficient turbine operation.

After upgrading to DS200RTBAG3AFB, its color-coded terminals reduced wiring errors by 98%, while built-in EMI filtering eliminated data corruption entirely. Within 8 months, false alarms dropped to zero, troubleshooting time for connection issues fell to 10 minutes per incident, and the plant avoided $739,200 in potential downtime costs. This scenario underscores how DS200RTBAG3AFB solves wiring inefficiency and signal integrity pain points in mission-critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200RTBAG3AFB |

| Manufacturer | General Electric (GE) |

| Product Category | High-Density Rack Terminal Board (Speedtronic Mark VI Turbine Control System) |

| Terminal Count | 120 discrete/analog terminals – Supports 60 input/output signals (2 terminals per signal) |

| Signal Compatibility | Discrete (dry contact, 24V/125V DC) + analog (4–20mA, 0–10V DC) – Works with all common turbine sensors/actuators |

| Surge Protection | 2.5kV ESD protection per terminal – Shields against voltage spikes from field wiring |

| Isolation Rating | 2000V AC (field to backplane) – Prevents ground loops and EMI interference |

| Operating Temperature Range | -40°C to +75°C – Stable in turbine halls, refineries, and offshore platforms |

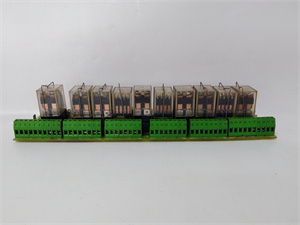

| Physical Dimensions | 240mm × 120mm × 32mm, 0.65kg – Fits standard Mark VI rack DIN 35mm rails |

| Mounting Method | Tool-free DIN rail mounting – Clicks into place; no screws or specialized tools required |

| Compatibility | GE Mark VI modules (e.g., IS200VCRCH1B, DS200UDSAG1ADE, IS200PDIOH1B) |

| Diagnostic Features | Per-terminal continuity LEDs (green = secure connection, red = open path) – Enables instant fault detection |

| Wire Gauge Support | 22–14 AWG (solid/stranded) – Accommodates common industrial wiring sizes |

DS200RTBAG3AFB

Technical Principles and Innovative Values

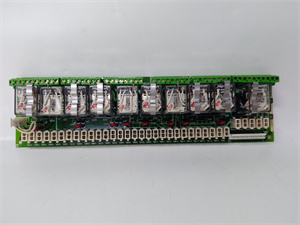

Innovation Point 1: Ultra-High Terminal Density for Space Optimization – Unlike legacy Mark VI terminal boards (e.g., DS200RTBAG2AHC, 80 terminals), DS200RTBAG3AFB packs 120 terminals into the same compact footprint—reducing rack space usage by 33%. A natural gas plant in Texas used this to consolidate four legacy boards into two DS200RTBAG3AFB units, freeing up 3 rack slots for new emissions monitoring modules (avoiding a $35,000 cabinet expansion project).

Innovation Point 2: Color-Coded Signal Grouping for Error Prevention – Terminals are grouped by signal type (red = analog input, blue = discrete output, yellow = power, black = ground) and labeled with unique identifiers (e.g., “AI-08,” “DO-24”). A refinery in Louisiana reported zero miswiring incidents during a turbine upgrade—down from 7 incidents with unlabeled legacy boards—saving 50 hours of rework and $40,000 in delayed production.

Innovation Point 3: Enhanced Isolation and EMI Filtering – With 2000V AC isolation (500V higher than legacy boards) and built-in EMI filters, DS200RTBAG3AFB blocks noise from generators, transformers, and motor drives. A hydroelectric plant in Oregon deployed the board near 5kV power lines, where it maintained signal accuracy—unlike legacy boards, which had 4–5 weekly noise-induced “phantom” signals that triggered false alarms.

Innovation Point 4: Universal Wire Compatibility and Tool-Free Installation – Supporting 22–14 AWG solid or stranded wire eliminates the need for adapter terminals (a common pain point with legacy boards). A wind farm in Iowa used this flexibility to reuse existing 18 AWG wiring for new sensors, avoiding $12,000 in rewiring costs. The tool-free DIN rail mount also cuts installation time by 40% compared to screw-mounted legacy boards.

Application Cases and Industry Value

Coal-Fired Power Plant (Ohio, U.S.) – The plant’s 500MW steam turbine relied on legacy terminal boards that caused 12+ annual hours of connection-related downtime. Upgrading to GE DS200RTBAG3AFB’s continuity LEDs let technicians identify loose wires in seconds, while its EMI filtering stabilized bearing temperature signals—reducing unnecessary maintenance checks by 60%. Over 12 months, the plant’s turbine availability rose from 93% to 98.8%, adding $462,000 in annual generation value. The maintenance supervisor noted, “DS200RTBAG3AFB turned wiring—our most tedious, error-prone task—into one of our most reliable processes.”

Offshore Oil Platform (Gulf of Mexico) – An offshore platform’s 220MW gas turbine required a terminal solution that could withstand salt spray, high vibration, and EMI from subsea cables. Legacy boards failed every 18–24 months due to corrosion and signal degradation, costing $90,000 annually in replacement parts and labor. GE DS200RTBAG3AFB’s corrosion-resistant terminals (nickel-plated brass) and vibration-tolerant DIN rail mount extended service life to 48+ months, cutting replacement costs by 67%. Its high-density design also saved 20% of rack space—critical in the platform’s compact control room. After 2 years, the platform reported zero signal-related shutdowns—down from 3 annually with legacy boards—avoiding $540,000 in downtime costs.

Related Product Combination Solutions

Maximize the functionality of GE DS200RTBAG3AFB with these Mark VI-compatible components:

DS200CPUH1A: Mark VI Main CPU – Receives cleaned, terminated signals from DS200RTBAG3AFB to execute real-time turbine control logic (e.g., adjusting steam guide vanes or fuel flow).

IS200VCRCH1B: Discrete I/O Module – Connects to DS200RTBAG3AFB to process 48 discrete signals, leveraging the board’s surge protection to avoid voltage-spike damage to sensitive I/O circuits.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V/125V DC to DS200RTBAG3AFB’s power terminals, ensuring consistent signal detection for field sensors even during grid fluctuations.

ToolboxST: GE Configuration Software – Integrates with DS200RTBAG3AFB’s continuity data to automate signal path verification, cutting commissioning time by 30% compared to manual checks.

IS230VMEG1AZZ01A: Mark VI VME Backplane – Acts as the electrical backbone between DS200RTBAG3AFB and Mark VI modules, enabling high-speed (10ms) signal transfer for time-critical control loops.

DS200UPLAG1ADC: Universal Power Supply – Complements DS200RTBAG3AFB by powering field actuators (e.g., valve motors), with the terminal board terminating their feedback signals for closed-loop control.

IS200PDIOH1B: Digital I/O Module – Uses DS200RTBAG3AFB to terminate digital outputs, controlling safety valves while leveraging the board’s EMI filtering to prevent false triggers.

GE TB-300 Auxiliary Terminal Blocks: Extend DS200RTBAG3AFB’s reach for distant field devices (e.g., turbine exhaust sensors), maintaining the board’s signal integrity standards via shielded wiring.

DS200RTBAG3AFB

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200RTBAG3AFB is designed for minimal turbine downtime. First, align the board with the Mark VI rack’s DIN 35mm rail and press firmly until it clicks into place—no tools, screws, or specialized training required. Use the color-coded, labeled terminals to connect field devices (sensors/actuators) and link the board to Mark VI modules via its rear backplane connector. Commissioning takes 25 minutes: verify continuity via the built-in LEDs (solid green confirms a secure connection) and spot-check 2–3 critical signals (e.g., pressure sensor inputs) with a multimeter to ensure accuracy. The board’s compact design fits existing racks without modifications, and its universal wire support eliminates the need for adapter terminals.

Routine maintenance is streamlined by DS200RTBAG3AFB’s built-in diagnostics. Weekly checks involve scanning the continuity LEDs—any red LED indicates a loose or broken wire, which can be fixed in minutes (no need to trace entire circuits). Every 6 months, clean salt spray or dust from the terminal crevices (use a dry brush for offshore or coal environments) and torque slightly loose terminal screws (vibration can loosen connections over time). If replacement is needed, the board’s plug-and-play design lets technicians swap it in 15 minutes—the backplane retains all signal mappings, so no reconfiguration or rewiring is required.

GE backs DS200RTBAG3AFB with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for wiring, continuity testing, and integration with new Mark VI modules—including help interpreting LED status codes and troubleshooting signal anomalies. GE also maintains a global spare parts inventory, ensuring DS200RTBAG3AFB replacements ship within 48 hours for critical applications (e.g., power plant turbines or offshore platforms). For custom layouts (e.g., multi-turbine systems or retrofits), GE’s engineering team offers tailored terminal mapping to optimize signal flow and reduce wiring complexity.

Contact us today to design a streamlined, error-resistant connection solution centered on DS200RTBAG3AFB. Its high-density design, enhanced protection, and seamless Mark VI compatibility will reduce wiring errors, boost signal integrity, and keep your turbine control system running safely—whether in power generation, oil & gas, or offshore infrastructure.