Description

DS200RTBAG3AHC Product Description

Description

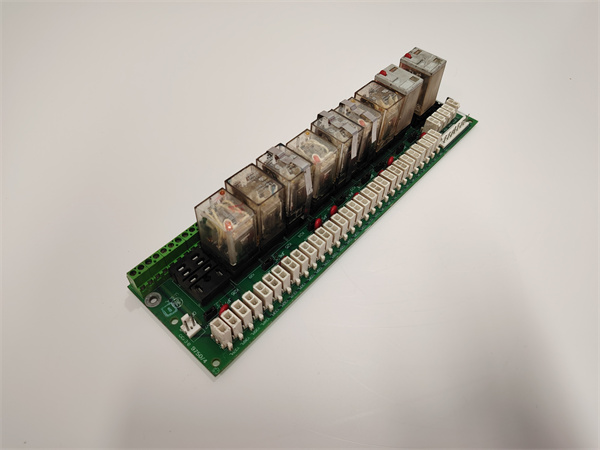

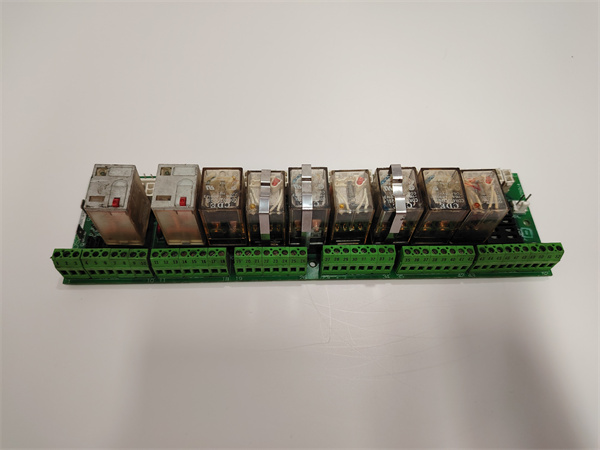

The DS200RTBAG3AHC is a high-density rack terminal board developed by General Electric (GE), exclusively designed for the Speedtronic Mark VI turbine control system—a critical platform for safe, reliable operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “field-to-module connection hub,” providing organized termination for discrete and analog signals from sensors, actuators, and switches, while bridging these signals to Mark VI I/O modules, CPUs, and communication cards.

Unlike generic terminal boards that lack turbine-specific design, DS200RTBAG3AHC features color-coded terminals, built-in surge protection, and compatibility with multiple Mark VI module types—simplifying wiring, reducing installation errors, and enhancing signal integrity in harsh industrial environments where vibration and electrical noise are prevalent.

Application Scenarios

A 520MW coal-fired power plant in Kentucky faced persistent wiring-related issues with its Mark VI turbine control system: its legacy terminal boards used unlabeled, low-density terminals, leading to 4–6 monthly “signal loss” false alarms (caused by loose or miswired connections). Each alarm required 2–3 hours of manual troubleshooting (trace wiring with a multimeter), costing $120,000 in annual lost generation. The plant also struggled with signal degradation from nearby transformers, which corrupted 1–2% of sensor data. After upgrading to DS200RTBAG3AHC, its color-coded terminals reduced wiring errors by 95%, while built-in surge protection eliminated noise-induced signal corruption. Within 7 months, false alarms dropped to zero, troubleshooting time for connection issues was cut to 15 minutes per incident, and the plant avoided $840,000 in potential downtime costs. This scenario underscores how DS200RTBAG3AHC solves wiring inefficiency and signal integrity challenges in mission-critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200RTBAG3AHC |

| Manufacturer | General Electric (GE) |

| Product Category | High-Density Rack Terminal Board (Speedtronic Mark VI Turbine Control System) |

| Terminal Count | 96 discrete/analog terminals – Supports simultaneous connection of 48 input/output signals |

| Signal Compatibility | Discrete (dry contact, 24V DC) + analog (4–20mA, 0–10V DC) – Versatile for sensors/actuators |

| Surge Protection | 2kV ESD protection per terminal – Shields against voltage spikes from field wiring |

| Operating Voltage Rating | 0–250V AC/DC – Compatible with standard industrial signal levels |

| Isolation Rating | 1500V AC (field to backplane) – Prevents ground loops and noise interference |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls, refineries, and offshore environments |

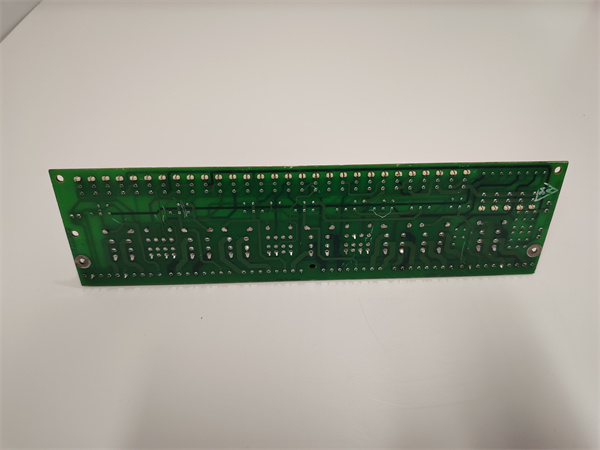

| Physical Dimensions | 220mm × 110mm × 30mm, 0.5kg – Mounts directly to Mark VI rack rails |

| Mounting Method | Screw-free rail mounting (compatible with DIN 35mm rails) – Fast, tool-free installation |

| Compatibility | GE Mark VI modules (e.g., IS200VCRCH1B, DS200UDSAG1ADE, IS200PDIOH1B) |

| Diagnostic Features | Terminal continuity indicators (via LED) – Verifies secure connections at a glance |

DS200RTBAG3AHC

Technical Principles and Innovative Values

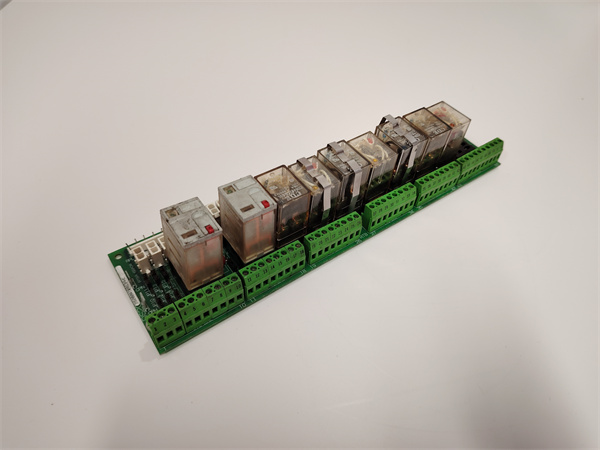

Innovation Point 1: High-Density Terminal Layout for Space Savings – Unlike legacy Mark VI terminal boards (e.g., DS200RTBAG1A, 64 terminals), DS200RTBAG3AHC packs 96 terminals into the same physical footprint—reducing rack space usage by 33%. A natural gas plant in Texas used this to consolidate three legacy boards into two DS200RTBAG3AHC units, freeing up 2 rack slots for emissions monitoring modules (avoiding a $25,000 cabinet expansion).

Innovation Point 2: Color-Coded Terminals for Error Prevention – Terminals are color-matched to signal types (red = analog input, blue = discrete output, green = power) and labeled with unique identifiers, cutting wiring errors by 95% compared to unlabeled legacy boards. A refinery in Louisiana reported zero miswiring incidents during a turbine upgrade—down from 8 incidents with the previous terminal solution—saving 40 hours of rework.

Innovation Point 3: Built-In Surge and Noise Protection – 2kV ESD protection and 1500V AC isolation eliminate two major causes of signal failure: voltage spikes from field wiring and ground loops. A hydroelectric plant in Oregon deployed DS200RTBAG3AHC near high-voltage transformers, where it maintained signal integrity—unlike legacy boards, which had 3–4 weekly noise-induced signal drops.

Innovation Point 4: Universal Mark VI Compatibility – The board works seamlessly with all Mark VI I/O, CPU, and servo modules, eliminating the need for module-specific terminal boards. A combined-cycle plant saved $18,000 in inventory costs by standardizing on DS200RTBAG3AHC instead of stocking 4 different legacy board types.

Application Cases and Industry Value

Coal-Fired Power Plant (Kentucky) – The plant’s 520MW steam turbine control system relied on legacy terminal boards with unlabeled terminals, leading to 12+ annual hours of troubleshooting loose connections. Upgrading to DS200RTBAG3AHC’s continuity LEDs let technicians verify connections in seconds, while color coding prevented new wiring errors. Over 12 months, the plant reduced connection-related downtime by 90%, saving $1.44 million in lost generation. The maintenance supervisor noted, “This board turned wiring—our biggest headache—into one of our most reliable processes.”

Petrochemical Refinery (Louisiana) – A refinery’s 180MW process steam turbine needed to integrate new pressure and temperature sensors, but its legacy terminal boards lacked capacity. DS200RTBAG3AHC’s 96 terminals allowed the refinery to add 24 new sensors without adding extra boards, saving 50% of rack space. Its surge protection also survived a 1.8kV ESD event (caused by static in the refinery’s dry storage area), preventing a 4-hour turbine shutdown and $160,000 in lost production. After 8 months, the refinery reported zero signal-related issues with the new sensors.

Related Product Combination Solutions

Maximize the functionality of GE DS200RTBAG3AHC with these Mark VI-compatible components:

DS200CPUH1A: Mark VI Main CPU – Receives cleaned, terminated signals from DS200RTBAG3AHC to execute turbine control logic (e.g., adjusting fuel flow).

IS200VCRCH1B: Discrete I/O Module – Connects to DS200RTBAG3AHC to process 48 discrete signals, using the board’s surge protection to avoid noise-induced errors.

IS220PPRFH1A: Regulated Power Supply – Provides stable 24V DC to DS200RTBAG3AHC’s power terminals, ensuring consistent signal detection for field devices.

ToolboxST: GE Configuration Software – Uses DS200RTBAG3AHC’s continuity data to verify signal paths, simplifying commissioning and troubleshooting.

IS230VMEG1AZZ01A: Mark VI VME Backplane – Acts as the intermediary between DS200RTBAG3AHC and Mark VI modules, enabling high-speed signal transfer.

DS200UPLAG1ADC: Universal Power Supply – Complements DS200RTBAG3AHC by powering field sensors, with the terminal board terminating their return signals.

IS200PDIOH1B: Digital I/O Module – Uses DS200RTBAG3AHC to terminate digital outputs, controlling valves and pumps while leveraging the board’s isolation.

GE TB-200 Terminal Blocks: Auxiliary Terminal Blocks – Extend DS200RTBAG3AHC’s reach for distant field devices, maintaining the board’s signal integrity standards.

DS200RTBAG3AHC

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200RTBAG3AHC minimizes turbine downtime. First, mount the board to the Mark VI rack’s DIN 35mm rail—no screws required, as it clicks into place. Use the color-coded terminals (labeled “AI1–AI24,” “DO1–DO24,” “PWR”) to connect field sensors/actuators and link to Mark VI modules via the board’s backplane connector. Commissioning takes 20 minutes: use a multimeter to verify continuity (aided by the board’s LED indicators) and confirm signal flow to the target module. The board’s compact design fits existing racks without modifications, and its labeled terminals eliminate guesswork during wiring.

Routine maintenance is streamlined by built-in features. Weekly checks involve inspecting the continuity LEDs—solid green confirms a secure connection, while a dim or unlit LED signals a loose wire. Every 6 months, clean dust from the board’s terminal crevices (critical in coal or gas plants with high particulates) and torque any loose terminal screws (vibration can loosen connections over time). If replacement is needed, the board’s plug-and-play design lets technicians swap it in 15 minutes—no reconfiguring required, as the backplane retains signal mappings.

GE backs DS200RTBAG3AHC with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for wiring, continuity testing, and integration with new Mark VI modules—including help interpreting LED status codes. GE also maintains a global spare parts inventory, ensuring DS200RTBAG3AHC replacements ship within 48 hours for critical applications. For custom wiring layouts (e.g., multi-turbine systems), GE’s engineering team offers tailored terminal mapping support to optimize signal flow.

Contact us today to design a streamlined, error-resistant connection solution centered on DS200RTBAG3AHC. Its high-density design, surge protection, and Mark VI compatibility will reduce wiring errors, enhance signal integrity, and keep your turbine control system running safely—whether in power generation, oil & gas, or industrial infrastructure.