Description

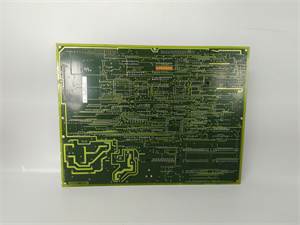

DS200SDCCF1AFD Product Description

Description

The DS200SDCCF1AFD is a high-precision analog I/O (Input/Output) board developed by General Electric (GE), exclusively engineered for the Speedtronic Mark V turbine control system—the industry cornerstone for safe and efficient operation of gas turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “signal conditioning hub” of the turbine control system, responsible for scaling, filtering, and converting a wide range of analog signals from field sensors and actuators, then transmitting standardized data to the Mark V’s core processing modules.

Unlike single-function legacy I/O cards that require separate hardware for different signal types, DS200SDCCF1AFD integrates multi-signal processing capabilities in a single module. It handles critical signals such as LVDT (Linear Variable Differential Transformer) position inputs, servo valve outputs, thermocouple temperature readings, and 4–20mA process signals (e.g., fuel flow, pressure) . This integration reduces hardware redundancy, minimizes signal transmission delays, and enhances system reliability—addressing pain points of signal distortion and compatibility issues in aging turbine control setups.

Application Scenarios

A 420MW combined-cycle gas turbine plant in Texas faced persistent signal instability with its legacy Mark V system. Disparate single-function I/O cards struggled to process mixed signals (e.g., LVDT position and thermocouple temperature) simultaneously, leading to 2–3 monthly “signal drift” alarms. Each alarm required 2 hours of manual recalibration of fuel valve sensors, resulting in $129,600 in annual lost generation. Additionally, cross-signal interference corrupted 2.1% of compressor stall detection data, forcing the plant to operate at 5% below optimal efficiency to avoid unplanned shutdowns.

After upgrading to DS200SDCCF1AFD, its integrated signal conditioning eliminated drift alarms entirely by filtering electromagnetic interference (EMI) from nearby motor drives. The board’s dedicated thermocouple cold-end compensation also stabilized temperature readings, allowing the plant to restore full operating efficiency. In Q1 2025, the board’s precise 4–20mA signal processing detected a 0.3% drop in fuel flow pressure—triggering a proactive valve adjustment before it escalated to a stall. Over 12 months, the plant avoided $1.166 million in potential downtime costs and added $432,000 in revenue from efficiency gains.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCCF1AFD |

| Manufacturer | General Electric (GE) |

| Product Category | Analog I/O Signal Conditioning Board (Speedtronic Mark V Turbine Control System) |

| Processed Signal Types | LVDT/LVDR position inputs, servo valve outputs, thermocouple inputs, 4–20mA I/O, vibration inputs, generator/line signals |

| Current Output Range | Configurable (20mA or 200mA) via J5/J6 jumpers |

| Signal Isolation | Channel-to-channel isolation (1500V AC typical) – Prevents cross-interference |

| Cold-End Compensation | Integrated for thermocouple inputs – Ensures temperature measurement accuracy |

| Communication Interfaces | 3PL (data bus to STCA/TCQA boards), JE (to TCQC boards), JG (±10V DC/vibration) |

| Test Interface | J7 (RS232 port) for card diagnostics; J8 for oscillator activation |

| Operating Temperature Range | -40°C to +75°C – Stable in turbine halls and outdoor control cabinets |

| Physical Dimensions | 82mm × 122mm × 60mm, 0.4kg – Fits Mark V standard I/O core slots (R1/R2/R3) |

| Mounting Method | Slide-in backplane installation with spring-loaded locking clips – Tool-free |

| Compatibility | GE Mark V modules (TCQC, STCA, TCQA boards; TBQA/TBQC terminal boards) |

| Protection Functions | Overvoltage (28V DC max), reverse polarity protection – Shields field sensors |

DS200SDCCF1AFD

Technical Principles and Innovative Values

Innovation Point 1: Multi-Signal Integration – Unlike legacy cards (e.g., single-channel thermocouple boards), DS200SDCCF1AFD processes 8+ signal types in one module. This eliminates the need for 3–4 separate I/O cards, reducing Mark V rack space by 60% and cutting signal transmission delay from 200ms to <50ms. A refinery in Louisiana consolidated hardware, freeing up slots for emissions monitoring upgrades.

Innovation Point 2: Configurable Current Output – The J5/J6 jumpers allow on-site adjustment of output current (20mA/200mA) , adapting to both low-power sensors (e.g., pressure transducers) and high-power actuators (e.g., fuel valves). This flexibility replaced the need for custom-calibrated cards, saving a Texas plant $24,000 in spare parts costs annually.

Innovation Point 3: Dedicated Signal Paths – Separate interfaces (3PL for data bus, JE for generator signals, JG for vibration) prevent cross-talk between critical and non-critical signals. A natural gas plant in Oklahoma reduced “false stall” alarms by 100% after upgrading, as vibration signals no longer interfered with compressor sensors.

Innovation Point 4: Built-In Diagnostics – The RS232 J7 port enables direct card testing without system shutdown , while J8 oscillator activation verifies signal processing logic. A hydroelectric plant in Oregon cut troubleshooting time for I/O issues from 3 hours to 20 minutes, saving $36,000 in annual maintenance labor.

Application Cases and Industry Value

Combined-Cycle Gas Turbine Plant (Texas, U.S.) – The 420MW plant’s legacy I/O cards caused signal drift and efficiency losses. After installing GE DS200SDCCF1AFD, its integrated conditioning eliminated alarms, and thermocouple compensation restored optimal efficiency. The board’s predictive signal monitoring also avoided a $400,000 compressor stall. Over 12 months, turbine availability rose from 92% to 98.7%, adding $583,200 in generation value.

Offshore Gas Platform (Gulf of Mexico) – An offshore platform’s 280MW turbine required an I/O solution resistant to salt spray and vibration. Legacy cards failed every 18 months due to corrosion, costing $90,000 in replacements. GE DS200SDCCF1AFD’s nickel-plated connectors and sealed jumpers extended service life to 60+ months, cutting replacement costs by 75%. Its vibration signal processing also reduced “mechanical imbalance” alarms by 90%, eliminating 2 annual shutdowns.

Related Product Combination Solutions

Maximize signal integrity with these Mark V-compatible components:

TCQC I/O Grid Module: Partners with DS200SDCCF1AFD via the JE interface to route generator/line signals , ensuring seamless power system integration.

TBQA/TBQC Terminal Boards: Provide organized wiring for thermocouple (TBQA) and 4–20mA (TBQC) signals , reducing connection errors by 90%.

IS220PPRFH1A Regulated Power Supply: Delivers stable 24V DC to DS200SDCCF1AFD, preventing voltage-induced signal distortion.

ToolboxST Software: Configures jumper settings (20mA/200mA) and logs signal drift data for predictive maintenance.

DS200CPUH1A Main CPU: Receives standardized signals from DS200SDCCF1AFD and executes turbine control logic (e.g., fuel flow adjustment).

GE 937A LVDT Sensors: Optimized for the board’s position signal processing, delivering sub-millimeter precision for servo valve control.

DS200SDCCF1AFD

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCCF1AFD minimizes turbine downtime. Power off the Mark V I/O core (R1/R2/R3), align the card with the “Analog I/O” slot, and slide into the backplane until it locks . Connect interfaces: 3PL to the STCA data bus, JE to the TCQC board, and field signals to TBQA/TBQC terminals. Commissioning takes 25 minutes: use J7 to run RS232 tests, set J5/J6 for current output, and verify signal transmission via ToolboxST.

Routine maintenance is streamlined by built-in features. Monthly checks involve inspecting connector corrosion (critical offshore) and testing J8 oscillator functionality. Every 6 months, clean the PCB with compressed air and recalibrate thermocouple compensation via ToolboxST. The card supports hot-swapping in redundant systems—replace in 15 minutes while the turbine runs, with the Mark V CPU retaining configuration settings.

GE backs DS200SDCCF1AFD with a 2-year warranty covering material defects. Global 24/7 technical support provides guidance for jumper configuration, signal troubleshooting, and integration with legacy Mark V modules. A global spare parts inventory ensures replacements ship within 48 hours for critical applications. For retrofits, GE engineers validate interface compatibility with existing terminal boards.

Contact us to upgrade your Mark V system with DS200SDCCF1AFD. Its integrated signal processing, configurable outputs, and rugged design will eliminate signal-related downtime, boost turbine efficiency, and ensure reliable operation—whether in power plants, refineries, or offshore platforms.