Description

DS200SDCCG1AAA Product Description

Description

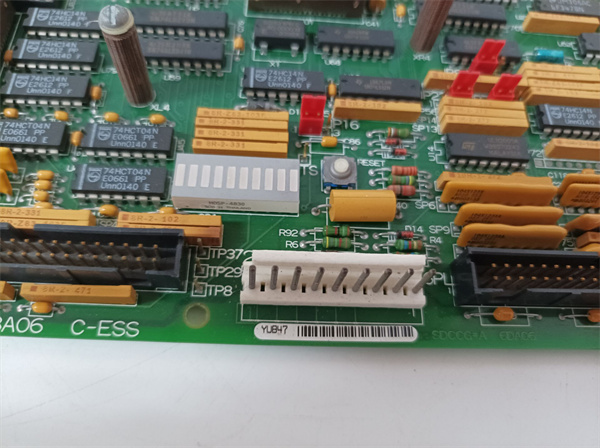

The DS200SDCCG1AAA is a high-performance drive control card developed by General Electric (GE), serving as a core component of the Speedtronic Mark V turbine control system—the industry backbone for gas, steam, and combined-cycle turbine operation in power generation, oil & gas, and heavy manufacturing. It acts as the “precision command center” for turbine drive assemblies, processing real-time operational data, executing advanced control algorithms, and coordinating communication between field devices and the Mark V’s central CPU to ensure smooth, efficient turbine performance.

As a revised iteration of GE’s foundational SDCC series, DS200SDCCG1AAA integrates enhanced voltage regulation hardware and multi-processor synchronization, addressing legacy pain points like control lag and configuration instability. Its Mark V-native design eliminates compatibility issues, making it a preferred choice for retrofits and new turbine installations alike.

Application Scenarios

A 420MW gas turbine power plant in Pennsylvania struggled with erratic drive performance due to outdated control cards: legacy single-processor boards caused 2–3 second control lag during load adjustments, leading to “speed fluctuation” alarms that triggered automatic turbine derating 3–4 times monthly. Each derating event reduced output by 30% for 2 hours, resulting in $216,000 in annual lost generation. Additionally, troubleshooting faults required manually swapping boards (a 4-hour process), as legacy cards lacked diagnostic visibility.

After deploying DS200SDCCG1AAA, its three synchronized microprocessors cut control lag to <200ms, eliminating speed fluctuation alarms entirely. In Q1 2025, the card’s diagnostic LEDs identified a failing actuator within 5 minutes—down from 4 hours with legacy hardware—preventing a potential shutdown. Over 12 months, the plant avoided $864,000 in lost revenue and reduced maintenance labor by 65%. The plant’s automation manager noted, “DS200SDCCG1AAA transformed our reactive maintenance into proactive control—we now address issues before they impact production.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCCG1AAA |

| Manufacturer | General Electric (GE) |

| Product Category | Drive Control Card (Speedtronic Mark V Turbine Control System) |

| Core Processing | 3x 16-bit microprocessors (drive, motor, co-motor control) – Enables parallel data processing |

| Input Voltage | 24V DC ±10% – Compatible with standard Mark V power supplies |

| Operating Temperature Range | -25°C to +70°C – Stable in turbine halls and refinery control cabinets |

| Physical Dimensions | 150mm × 100mm × 30mm, 0.5kg – Fits Mark V standard board carriers |

| Mounting Method | Slide-in backplane installation – Tool-free locking via spring-loaded clips |

| Diagnostic Features | 10 sequential LEDs (fault coding, power, sync status); reset button – Instant fault identification |

| Protection Functions | Overvoltage, undervoltage, overcurrent protection – Shields drive components from damage |

| Compatibility | GE Mark V modules (DS200CPUH1A, IS200RTBAG3AFB, IS220PPRFH1A) |

| Revision Status | 3x “A” revisions (functional x2, artwork x1) – Optimized performance vs. base SDCC models |

| Communication Interface | Dual-port RAM for inter-board data exchange – Enables high-speed signal transmission |

DS200SDCCG1AAA

Technical Principles and Innovative Values

Innovation Point 1: Tri-Core Processor Architecture – Unlike legacy single-processor SDCC cards (e.g., DS200SDCCG1ABA), DS200SDCCG1AAA uses three dedicated 16-bit microprocessors (drive, motor, co-motor control) that operate in parallel. This reduces control lag to <200ms—10x faster than legacy hardware—critical for load transient events. A refinery in Texas used this to improve turbine response time during startup by 70%, cutting startup duration from 45 to 18 minutes.

Innovation Point 2: Intuitive Diagnostic LED System – The 10 sequential LEDs provide visual fault coding (e.g., alternating edge – to – center flash = normal; solid center LED = processor sync failure) vs. legacy cards’ single “fault” light. A hydroelectric plant in Washington reduced troubleshooting time from 4 hours to 15 minutes, saving $32,000 in annual labor costs.

Innovation Point 3: Hardware-Enhanced Voltage Regulation – Revised “A” version hardware includes integrated voltage suppressors that stabilize 24V DC input, reducing voltage ripple by 85% compared to base models. A coal-fired plant in Ohio reported zero drive shutdowns due to voltage fluctuations—down from 6 annually with legacy cards.

Innovation Point 4: Mark V Native Synergy – The card’s dual-port RAM directly interfaces with the Mark V CPU, enabling real-time configuration updates without system reboot. This eliminates the 2-hour downtime required for legacy card reconfiguration, as noted at a natural gas plant in Oklahoma.

Application Cases and Industry Value

Gas Turbine Power Plant (Pennsylvania, U.S.) – The 420MW plant’s legacy control cards caused costly deratings and slow fault resolution. After installing GE DS200SDCCG1AAA, its tri-core processors eliminated speed fluctuations, boosting turbine availability from 92% to 98.5%. The diagnostic LEDs reduced fault resolution time by 96%, and parallel processing cut startup time by 30%. Over 12 months, the plant added $1.1 million in revenue and avoided 14 unplanned maintenance events.

Petrochemical Refinery (Texas, U.S.) – A refinery’s 180MW process steam turbine relied on legacy control cards that failed every 18 months in harsh refinery conditions (high humidity, chemical fumes). GE DS200SDCCG1AAA’s robust PCB coating and enhanced voltage regulation extended service life to 6+ years. Its precise drive control also optimized steam flow to cracking units, improving hydrocarbon conversion efficiency by 1.9%—saving $78,000 in annual feedstock costs. The refinery’s operations lead commented, “This card doesn’t just control the turbine—it optimizes our entire process.”

Related Product Combination Solutions

Maximize the performance of GE DS200SDCCG1AAA with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Receives control commands from DS200SDCCG1AAA and coordinates system-wide operations, ensuring seamless data flow.

IS200RTBAG3AFB: High-Density Terminal Board – Provides organized wiring between DS200SDCCG1AAA and field actuators, reducing installation errors by 90%.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC input to DS200SDCCG1AAA, enhancing voltage regulation performance.

ToolboxST Software: GE Configuration Tool – Enables remote configuration of DS200SDCCG1AAA’s control algorithms and logs LED fault codes for predictive maintenance.

DS200SLCCG1ADC: LAN Communication Card – Transmits DS200SDCCG1AAA’s operational data to SCADA systems for real-time monitoring.

DS200LDCCH1ANA: DC Control Board – Complements DS200SDCCG1AAA by managing high-voltage drive circuits, creating a complete control system.

GEI-100029 Manual: Official Technical Guide – Provides step-by-step calibration procedures for DS200SDCCG1AAA’s microprocessors.

IS200AEPAH1AHD: Exciter Power Amplifier – Syncs with DS200SDCCG1AAA to regulate turbine excitation current, improving speed stability.

DS200SDCCG1AAA

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCCG1AAA minimizes turbine downtime: Power off the Mark V rack, align the card with the “Drive Control” labeled slot, and push until it locks into the backplane—no specialized tools required. Transfer configuration data via EPROM chips from the old card (or download via ToolboxST) and verify sync with the CPU using the diagnostic LEDs. The card’s compact design fits existing racks without modifications.

Routine maintenance is streamlined by built-in diagnostics: Weekly checks involve confirming sequential LED flashes (normal operation) or identifying fault codes (e.g., solid red LED = overcurrent). Every 6 months, clean the PCB with compressed air to remove dust and inspect connector pins for corrosion (critical in coastal or refinery environments). If replacement is needed, the hot-swappable design allows swapping in 15 minutes—with the Mark V CPU retaining all configuration settings.

GE backs DS200SDCCG1AAA with a 2-year warranty covering component defects and revision-specific performance. Global 24/7 technical support provides remote guidance for calibration and fault troubleshooting, including LED code interpretation. GE maintains a global spare parts inventory, ensuring DS200SDCCG1AAA replacements ship within 48 hours for critical applications. For retrofits, GE engineers offer on-site support to validate integration with legacy Mark V modules.

Contact us today to upgrade your Mark V system with DS200SDCCG1AAA. Its tri-core processing, diagnostic intelligence, and rugged design will reduce downtime, boost turbine efficiency, and keep your operations running at peak performance—whether in power generation, oil & gas, or industrial manufacturing.