Description

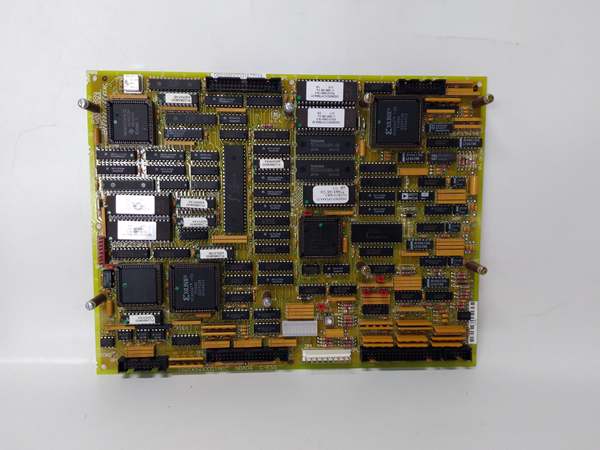

GE DS200SDCCG1AEC Product Description

Product Overview

The GE DS200SDCCG1AEC is a standard-version digital control and communication integration module, exclusively designed for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry workhorse in industrial power generation, regional utilities, and medium-scale energy facilities for managing gas, steam, and combined-cycle turbines. As a cost-effective “multi-tasking” component for auxiliary system control, GE DS200SDCCG1AEC undertakes three core roles: executing digital discrete control logic for turbine auxiliary equipment (e.g., cooling fan on/off, lube oil pump start/stop, valve opening/closing interlocks), providing basic communication interfaces to connect local monitoring devices (e.g., compact HMIs, data loggers, or auxiliary system controllers), and implementing simple sequential control (e.g., “start lube oil pump → delay 30s → start cooling fan”) to streamline auxiliary system startup/shutdown procedures.

Different from specialized modules such as the turbine base control-focused GE DS200TBQCG1AAA (core speed/load control) or relay-dedicated GE DS200RTBAG2AFB (high-current relay output), GE DS200SDCCG1AEC is positioned as a “general-purpose auxiliary controller” for medium-scale turbines (100MW–300MW). It optimizes the balance between discrete control channels and communication functions—providing sufficient I/O ports for auxiliary devices while avoiding the cost of redundant high-end features (e.g., ultra-precise timing or dual-core redundancy). By centralizing auxiliary discrete control and basic communication in a single Mark V-compatible slot, GE DS200SDCCG1AEC reduces the number of discrete I/O modules and communication converters in the control cabinet by 40%, simplifying wiring and lowering maintenance costs. For plant operators, GE DS200SDCCG1AEC acts as a “auxiliary system hub” of the Mark V system, ensuring coordinated operation of auxiliary equipment while meeting the cost-sensitive needs of industrial and regional turbine applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200SDCCG1AEC |

| Manufacturer | General Electric (GE) |

| Product Type | Standard-Version Digital Control & Communication Integration Module (Mark V Speedtronic) |

| Core Function | Auxiliary equipment discrete control; basic communication with local devices; simple sequential control |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v4.5+) |

| Digital I/O Ports | – Digital Inputs: 16 discrete inputs (24V DC, sinking/sourcing configurable; wet/dry contact compatible)- Digital Outputs: 12 discrete outputs (24V DC, 2A per channel; short-circuit protected) |

| Sequential Control | Supports 16 user-configurable sequential logic rules (e.g., delay-on-start, interlock-based stop); maximum sequence step: 8 |

| Communication Interfaces | – 1×RS-485 port (Modbus RTU slave/master configurable; baud rate: 300 bps–57.6 kbps)- 1×RS-232 port (for local HMI/data logger connection)- Mark V backplane bus (5Mbps, half-duplex; for data synchronization with Mark V main controller) |

| Control Logic | Supports ladder logic programming (via Mark V HMI); basic logic functions: AND/OR/NOT, timer, counter |

| Output Protection | Each digital output has overcurrent (2.5A) and short-circuit protection; automatic recovery after fault removal |

| Input Filtering | Configurable digital input filter (1ms–100ms) to suppress electromagnetic interference (EMI) |

| Power Input | 24V DC (±15% tolerance); backplane-powered with non-isolated 5V DC for logic circuits |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 38mm (D) (Mark V standard single-slot form factor) |

| Weight | ~450g (includes I/O circuits and communication modules) |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61000-6-2 (industrial EMI immunity) |

| Diagnostic Features | Digital output short-circuit/overcurrent alert; input signal loss detection; communication error logging; power supply status monitoring |

DS200SDCCG1AEC

Key Differentiators vs. Specialized Modules

To meet the integrated needs of auxiliary systems, GE DS200SDCCG1AEC differs from specialized modules in functional positioning:

| Feature | GE DS200SDCCG1AEC (Digital Control & Communication) | GE DS200TBQCG1AAA (Turbine Base Control) | GE DS200RTBAG2AFB (Relay Control) | Application Fit |

| Control Focus | Auxiliary discrete control (on/off, sequencing) | Core speed/load control | High-current relay output (hardwired) | Manages auxiliary equipment (fans, pumps, valves) |

| I/O Type | Digital (16 inputs/12 outputs, 2A) | Analog (speed/load signals) | Relay (10A AC/15A DC) | Suitable for low-to-medium current auxiliary devices |

| Communication | RS-232/RS-485 (local HMI/data loggers) | Governor interface (4–20mA) | No dedicated communication | Connects local monitoring devices without external converters |

| Sequential Logic | 16 rules (simple startup/shutdown sequences) | No sequential control | Basic timing (no interlock logic) | Automates auxiliary system procedures (e.g., pre-start checks) |

| Cost Position | Mid-low (integrated functions reduce module count) | Mid-high (core control focus) | Mid (specialized relay output) | Cost-effective for auxiliary system integration |

Main Features and Advantages

Adequate Digital I/O for Auxiliary Systems: GE DS200SDCCG1AEC provides 16 digital inputs and 12 digital outputs—sufficient to control the auxiliary equipment of most medium-scale turbines, including 4 cooling fans, 3 lube oil pumps, 2 seal oil pumps, and 3 emergency valves (with remaining I/Os for status monitoring). Each 2A digital output supports direct control of low-to-medium current devices (e.g., 24V DC fan motors) without external contactors, reducing component count. A 120MW industrial steam turbine plant in Northern China used this module to control 8 auxiliary devices, replacing 2 discrete I/O modules and reducing cabinet wiring by 50%.

Integrated Communication for Local Monitoring: With built-in RS-232/RS-485 ports, the module enables direct connection to local devices such as compact HMIs (e.g., GE QuickPanel) or data loggers—eliminating the need for external serial converters. The RS-485 port supports Modbus RTU master mode, allowing it to poll auxiliary sensor data (e.g., fan vibration switches, pump temperature sensors) and transmit integrated status to the Mark V system via the backplane. A 180MW gas turbine plant in Southeast Asia used the RS-232 port to connect a local data logger, realizing 24/7 recording of auxiliary equipment run hours and fault events without additional communication modules.

Simple Sequential Control to Automate Procedures: The module supports 16 user-configurable sequential logic rules, enabling automation of auxiliary system startup/shutdown procedures. For example, a “pre-start sequence” can be set as: “Input 1 (lube oil tank level normal) → Start Output 1 (lube oil pump) → Delay 20s → Check Input 2 (lube oil pressure normal) → Start Output 2 (cooling fan)”. This avoids manual operation errors and shortens startup time. A 200MW combined-cycle plant in Southern Europe used this function to automate the auxiliary system pre-start process, reducing manual operation time from 15 minutes to 2 minutes and improving startup consistency.

Built-In Protection and EMI Immunity: Each digital output of the module has 2.5A overcurrent and short-circuit protection—preventing module damage caused by equipment overload or wiring errors. The configurable 1ms–100ms input filter suppresses electromagnetic interference from industrial environments (e.g., motor startup surges), ensuring stable input signal detection. A 150MW subcritical steam turbine plant in Central China reported zero false triggers or output faults after installing the module, resolving a persistent issue where EMI caused incorrect pump status signals.

Application Field

GE DS200SDCCG1AEC is widely used in the auxiliary systems of medium-scale Mark V-based turbines, focusing on two core application scenarios: industrial turbine auxiliary control and regional utility turbine auxiliary monitoring.

In industrial turbine auxiliary control, GE DS200SDCCG1AEC ensures process continuity. A 160MW industrial steam turbine plant in Eastern China (supporting a large steel mill) deployed the module to control its lube oil system (3 pumps), cooling system (4 fans), and seal system (2 pumps). The module’s sequential control automated the pre-start check process: only when all tank levels and pressure signals were normal would the pumps/fans start in sequence, avoiding equipment damage from low oil pressure. The RS-485 port polled 6 temperature sensors, transmitting data to the Mark V HMI for real-time monitoring—ensuring auxiliary equipment operated within safe temperature ranges.

In regional utility turbine auxiliary monitoring, GE DS200SDCCG1AEC simplifies local management. A 220MW gas turbine plant in Southwest Asia (supplying power to a provincial capital) used the module to integrate auxiliary equipment status and local monitoring. The RS-232 port connected a compact HMI in the auxiliary room, allowing on-site technicians to view pump/fan run status and fault alerts without accessing the main control room. The module’s digital outputs controlled 3 emergency isolation valves, with interlock logic linked to the Mark V system—triggering valve closure immediately if the turbine tripped, ensuring system safety.

Related Products

GE DS200TBQCG1AAA: Turbine base control module that collaborates with GE DS200SDCCG1AEC—the former manages core speed/load, while the latter controls auxiliary equipment.

GE DS200RTBAG2AFB: Relay control module that complements the module for high-current devices (e.g., 10A AC pumps) beyond the 2A output capacity of GE DS200SDCCG1AEC.

GE DS200PCCAG1ABB: Power control module that provides stable 24V DC to GE DS200SDCCG1AEC’s I/O and logic circuits, ensuring reliable operation.

GE QuickPanel 1000: Compact HMI compatible with the module’s RS-232 port, enabling local viewing of auxiliary equipment status.

GE DS200SIOBH1ABA: Serial communication module that expands the module’s communication capacity (e.g., adding more RS-485 ports for sensor networks) if needed.

GE IC660HHM501: Handheld diagnostic tool used to test the module’s digital I/O, verify sequential logic, and troubleshoot communication ports.

GE DS200TCEBG1ACE: Turbine protection module that sends emergency trigger signals to GE DS200SDCCG1AEC (e.g., overspeed) to shut down auxiliary equipment.

GE CR2000 Series Contactors: External contactors used with the module’s digital outputs to control high-current devices (e.g., 5A AC fans) exceeding 2A.

DS200SDCCG1AEC

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200SDCCG1AEC, confirm the Mark V system firmware is v4.5+ to support its sequential logic and communication functions. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to avoid damaging the module’s I/O circuits. Verify that the current of controlled devices does not exceed 2A per output—use external contactors for higher-current equipment. Configure input filters (typically 10ms for motor status signals) via the Mark V HMI to suppress EMI, and set sequential logic rules according to auxiliary system procedures (e.g., pre-start interlocks). Label I/O wires clearly (e.g., “Input 1: Lube Oil Level Switch”, “Output 1: Lube Oil Pump 1”) to simplify troubleshooting.

Maintenance recommendations: Perform weekly visual inspections of the module to check for loose I/O terminals, corrosion on connectors, or illuminated fault LEDs. Clean the module surface with a dry, lint-free cloth—avoid compressed air (which may dislodge internal components) or liquids. Monthly, test digital outputs by energizing each channel and verifying device operation (e.g., fan startup), and check digital inputs by simulating status changes (e.g., triggering a level switch). Quarterly, verify communication functions: test the RS-232 port by connecting a laptop to read data, and check the RS-485 port by polling Modbus sensors. Review diagnostic logs to identify recurring issues (e.g., frequent output short-circuits) and resolve root causes (e.g., replacing a faulty fan motor). For industrial environments with high dust or humidity, conduct semi-annual inspections of terminal block insulation to prevent short-circuits.

Product Guarantee

GE provides a 12-month standard warranty for GE DS200SDCCG1AEC, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61000-6-2 standards from the date of shipment. The warranty includes free replacement of faulty modules and 24/7 access to GE’s global technical support team—specializing in Mark V auxiliary control troubleshooting to resolve issues such as digital output faults, communication errors, or sequential logic malfunctions. For industrial power plants or regional utility projects, GE offers optional 18-month extended warranties and remote technical support, where technicians assist with module configuration, sequential logic programming, and communication setup. GE’s OEM-certified repair services for GE DS200SDCCG1AEC include I/O circuit testing, logic function verification, and communication port recalibration, with a 6-month post-repair warranty—ensuring long-term reliable operation of turbine auxiliary control systems.