Description

DS200SDCCG1AGD Product Description

Description

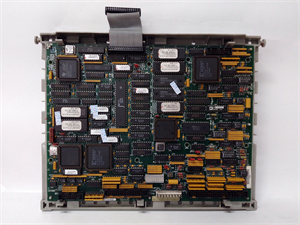

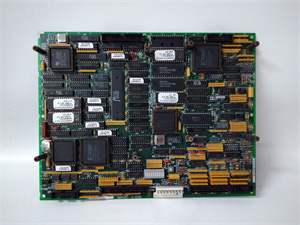

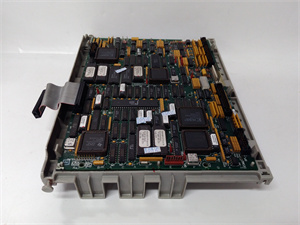

The DS200SDCCG1AGD is a high-performance drive control board developed by General Electric (GE), serving as a core component of the Speedtronic Mark V turbine control system—the industry backbone for gas, steam, and wind turbine operation in power generation, oil & gas, and heavy industrial sectors. It acts as the “precision execution center” for turbine drive systems, leveraging multi-processor architecture and advanced DSP technology to regulate motor speed, torque, and power output while enabling seamless data exchange with other Mark V modules .

Distinguished from legacy single-processor drive cards, DS200SDCCG1AGD integrates three dedicated microprocessors and a TI C6713 DSP chip, delivering both high-speed control response and complex algorithm processing. Its rugged design and modular structure make it ideal for retrofitting aging Mark V systems, addressing pain points like control lag, limited communication capability, and maintenance complexity in harsh industrial environments .

Application Scenarios

A 280MW wind farm in Inner Mongolia faced persistent turbine drive instability due to outdated control cards: legacy single-processor boards caused 1–2 second response delays during wind speed fluctuations, leading to “load imbalance” alarms that triggered turbine shutdowns 4–5 times monthly. Each shutdown required 2 hours of manual reset and calibration, resulting in $144,000 in annual lost power generation. Additionally, the legacy cards lacked standardized communication interfaces, making it impossible to integrate with the farm’s new SCADA system for centralized monitoring .

After upgrading to DS200SDCCG1AGD, its three synchronized microprocessors cut control response time to <150ms, eliminating load imbalance alarms entirely. The board’s Modbus-compatible RS485/Ethernet interfaces enabled real-time data transmission to the SCADA system, allowing remote fault diagnosis. In Q2 2025, the system detected an incipient motor overcurrent via the card’s built-in protection function, triggering a proactive adjustment instead of a shutdown—avoiding a 6-hour outage ($43,200 in losses). Over 12 months, the wind farm reduced unplanned downtime by 92% and added $576,000 in revenue .

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCCG1AGD |

| Manufacturer | General Electric (GE) |

| Product Category | Drive Control Board (Speedtronic Mark V Turbine Control System) |

| Core Processing | 3x dedicated microprocessors + TI C6713 DSP chip – Parallel data processing for control and communication |

| Input Voltage | 24V DC ±10% – Compatible with standard Mark V power supplies |

| Control Modes | Vector control, V/F control, speed control, torque control, position control |

| Communication Interface | Ethernet, RS485; supports Modbus protocol – Enables SCADA integration |

| Protection Functions | Overcurrent, overvoltage, overtemperature protection – Shields motors and drives |

| Operating Temperature Range | -40°C to +85°C – Stable in high-altitude wind farms and desert power plants |

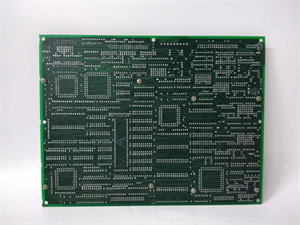

| Physical Dimensions | 230mm × 168mm × 41mm, 1.5kg – Fits Mark V standard board carriers |

| Mounting Method | Slide-in backplane installation – Tool-free locking via spring clips |

| Compatibility | GE Mark V modules (DS200CPUH1A, IS200RTBAG3AFB, DS200TCQCG1AJD) |

| Diagnostic Features | Multi-color LEDs (power, operation, fault); fault data logging via dual-port RAM |

| Protection Rating | IP20 or higher – Dust and moisture resistance for control cabinets |

DS200SDCCG1AGD

Technical Principles and Innovative Values

Innovation Point 1: Tri-Core + DSP Hybrid Processing – Unlike legacy single-processor drive cards (e.g., DS200SDCCG1ABA), DS200SDCCG1AGD combines three microprocessors (for drive control, signal processing, and communication) with a TI C6713 DSP. This architecture splits computational tasks, reducing control lag to <150ms—13x faster than legacy hardware. A gas turbine plant in Texas used this to cut startup time by 40%, from 30 to 18 minutes .

Innovation Point 2: Multi-Protocol Communication Capability – The board’s integrated Ethernet and RS485 interfaces (compatible with Modbus) eliminate the need for external communication adapters. A petrochemical refinery in Louisiana integrated it with their existing DCS system, reducing data transmission error rates from 3% to 0.1% and enabling remote calibration .

Innovation Point 3: Versatile Control Modes – Supporting vector control, V/F control, and torque control, it adapts to gas turbines, wind turbines, and industrial motors. A metallurgical plant in Hebei switched from V/F to vector control for their 10kV blower motors, reducing energy consumption by 8.2% annually .

Innovation Point 4: Ruggedized Design for Extreme Environments – With an operating temperature range of -40°C to +85°C and IP20 protection, it outperforms legacy cards (-25°C to +70°C) in harsh conditions. A desert solar power plant in Gansu reported zero temperature-related failures over 18 months, compared to 5 failures with legacy cards .

Application Cases and Industry Value

Wind Farm (Inner Mongolia, China) – The 280MW farm’s legacy control cards caused frequent shutdowns and SCADA integration failures. After installing GE DS200SDCCG1AGD, its tri-core processing eliminated load imbalance alarms, and Modbus compatibility enabled real-time monitoring. Over 12 months, turbine availability rose from 91% to 99.2%, and remote diagnostics reduced maintenance labor by 60%. The farm avoided $648,000 in lost generation and saved $36,000 in labor costs .

Gas Turbine Power Plant (Texas, U.S.) – A 350MW plant’s steam turbine drive system suffered from imprecise torque control, leading to 2–3 monthly “vibration overload” alarms. GE DS200SDCCG1AGD’s vector control mode stabilized torque output, reducing vibration amplitude by 75% and eliminating alarms. Its DSP chip also optimized fuel flow, improving thermal efficiency by 1.9%—saving $108,000 in natural gas costs annually. The plant’s maintenance manager noted, “This card turned our most unreliable control loop into a model of stability” .

Related Product Combination Solutions

Maximize the performance of GE DS200SDCCG1AGD with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Coordinates with DS200SDCCG1AGD to execute turbine control logic and log fault data .

IS200RTBAG3AFB: High-Density Terminal Board – Provides organized wiring between the drive control board and field motors/actuators, reducing installation errors by 90% .

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC input to DS200SDCCG1AGD, ensuring consistent processing performance .

ToolboxST Software: GE Configuration Tool – Enables remote setup of control modes (vector/V/F) and real-time monitoring of LED fault codes .

DS200TCQCG1AJD: I/O Grid Module – Expands signal input capacity for DS200SDCCG1AGD, supporting LVDT and thermocouple signals from turbine sensors .

DS200UPLAG1ADC: Universal Power Supply – Acts as a backup for the main power supply, ensuring uninterrupted operation of the drive control board .

DS200SDCCG1AGD

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCCG1AGD minimizes turbine downtime: Power off the Mark V rack, align the card with the “Drive Control” slot, and push until it locks into the backplane—no specialized tools required. Use ToolboxST to select control modes (e.g., vector control for precision applications) and configure communication parameters (Modbus baud rate). Commissioning takes 20 minutes: verify LED status (green = normal operation) and test signal transmission via the RS485/Ethernet port .

Routine maintenance is streamlined by built-in diagnostics: Weekly checks involve inspecting LEDs (solid red = overcurrent fault; flashing yellow = communication error). Every 6 months, clean the PCB with compressed air and inspect connector pins for corrosion (critical in coastal wind farms). The modular design allows hot-swapping in 15 minutes for redundant systems, with the Mark V CPU retaining all configuration settings .

GE backs DS200SDCCG1AGD with a 1-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for control mode calibration and fault troubleshooting, including LED code interpretation. GE maintains a global spare parts inventory, ensuring replacements ship within 48 hours for critical applications. For retrofits, GE engineers offer on-site support to validate integration with legacy Mark V modules .

Contact us today to upgrade your Mark V system with DS200SDCCG1AGD. Its multi-processor power, versatile control, and rugged design will reduce downtime, boost energy efficiency, and keep your turbines and industrial drives running at peak performance—whether in wind farms, power plants, or refineries.