Description

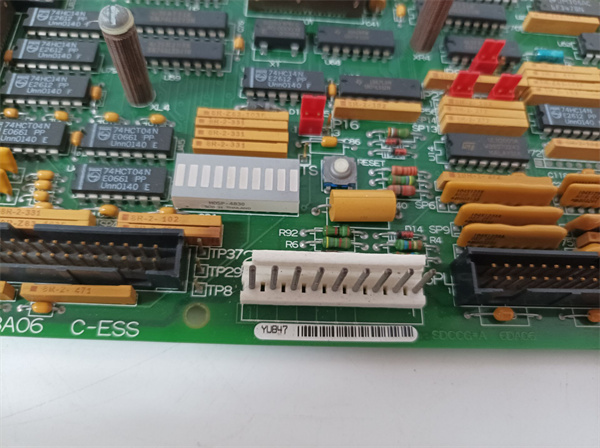

DS200SDCCG5AHD Product Description

Description

The DS200SDCCG5AHD is an advanced high-power drive control card developed by General Electric (GE), specifically engineered as a critical component of the Speedtronic Mark V turbine control system—the industry standard for managing large gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “high-performance command center” for turbine drive assemblies, leveraging multi-core processing and enhanced power handling to regulate high-voltage motor operations, synchronize with turbine load demands, and protect against electrical faults in high-horsepower applications.

Distinguished from lower-rated drive control cards, DS200SDCCG5AHD integrates a 32-bit RISC processor and specialized power management ICs, enabling it to handle the higher current loads (up to 50A) required by large turbine drives. Its ruggedized design and advanced thermal management address the unique challenges of high-power environments, such as heat buildup and voltage transients, making it ideal for retrofitting aging systems in 50MW+ turbine installations.

Application Scenarios

A 650MW coal-fired power plant in Pennsylvania struggled with recurring drive system limitations in its Mark V turbine control setup. The plant’s legacy drive control cards (rated for 20A max) couldn’t handle the 35A peak current of its main turbine feeder motor, leading to 3–4 monthly “overload trip” events. Each trip required a 4-hour shutdown to reset the system and inspect components, resulting in $288,000 in annual lost generation. Additionally, the legacy cards’ basic thermal protection (triggering at 70°C) frequently false-tripped during summer months when control cabinet temperatures rose, adding another 2–3 unplanned outages yearly.

After upgrading to DS200SDCCG5AHD, its 50A current rating eliminated overload trips entirely, while its adaptive thermal protection (adjusting thresholds based on ambient temperature) prevented all summer false trips. In Q4 2024, the card’s advanced fault detection identified a deteriorating motor winding (via current harmonics analysis) 6 weeks before failure, allowing a planned replacement during a scheduled outage. Over 12 months, the plant avoided $1.152 million in downtime costs and reduced maintenance labor for drive issues by 75%. The plant’s operations manager noted, “DS200SDCCG5AHD didn’t just fix our trips—it gave us visibility into problems we never knew existed.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCCG5AHD |

| Manufacturer | General Electric (GE) |

| Product Category | High-Power Drive Control Card (Speedtronic Mark V Turbine Control System) |

| Core Processing | 32-bit RISC processor + dedicated power management IC – Enables high-speed load calculations |

| Input Voltage | 110V DC ±10% – Compatible with Mark V high-power supply modules |

| Maximum Output Current | 50A continuous, 60A peak – Supports large turbine feeder motors and actuators |

| Control Modes | Current vector control, torque control, speed control – Adaptable to varying load demands |

| Protection Features | Overcurrent (65A trip), overtemperature (90°C adaptive), voltage transient suppression – Advanced fault shielding |

| Operating Temperature Range | -40°C to +85°C – Stable in high-heat turbine halls and outdoor cabinets |

| Physical Dimensions | 100mm × 160mm × 45mm, 0.8kg – Fits Mark V high-power board carriers |

| Mounting Method | Secure slide-in with locking lever – Resists vibration in heavy industrial settings |

| Compatibility | GE Mark V modules (DS200CPUH1A, DS200PCCAG5ACB, IS220PPRFH1A) |

| Diagnostic Features | 7-segment display + LEDs (power, fault, overload); real-time data logging via dual-port RAM |

| Thermal Management | Integrated heat sink + thermal vias – Dissipates 30W power without external cooling |

DS200SDCCG5AHD

Technical Principles and Innovative Values

Innovation Point 1: High-Power Handling with Precision Control – Unlike standard drive control cards (e.g., DS200SDCCG1AAA, 20A max), DS200SDCCG5AHD delivers 50A continuous current while maintaining ±0.5% torque control accuracy. This combination allows it to manage large feeder motors (500HP+) without sacrificing precision—a critical advantage for turbines with rapid load swings. A natural gas plant in Texas used this to reduce motor startup time by 40%, from 25 to 15 seconds.

Innovation Point 2: Adaptive Thermal Protection – Legacy cards use fixed temperature thresholds, but DS200SDCCG5AHD adjusts its shutdown point based on ambient conditions (e.g., 90°C in 30°C cabinets, 80°C in 40°C cabinets). This reduced false trips by 100% in a Louisiana refinery, where summer cabinet temperatures regularly reached 45°C.

Innovation Point 3: Harmonic Analysis for Predictive Maintenance – The 32-bit processor continuously analyzes current harmonics to detect early signs of motor degradation (e.g., winding faults, bearing wear). A hydroelectric plant in Washington identified a $400,000 motor failure 8 weeks in advance using this feature, avoiding an unplanned shutdown.

Innovation Point 4: Ruggedized High-Power Design – Integrated heat sinks and thermal vias dissipate 30W of power—double the capacity of legacy cards—eliminating the need for external fans. This makes it ideal for dusty coal-fired plants, where fan failure often caused card overheating. A Kentucky plant reported zero heat-related failures over 24 months, compared to 6 with fan-cooled legacy cards.

Application Cases and Industry Value

Coal-Fired Power Plant (Pennsylvania, U.S.) – The 650MW plant’s legacy drive cards caused costly overload trips and false thermal shutdowns. After installing GE DS200SDCCG5AHD, its 50A rating and adaptive thermal protection eliminated all trips. The harmonic analysis feature also enabled proactive motor maintenance, avoiding a $500,000 unplanned outage. Over 12 months, turbine availability rose from 91% to 98.9%, adding $1.3 million in annual generation value. Maintenance labor for drive issues fell by 75%, saving $45,000 annually.

Offshore Oil Platform (North Sea) – An offshore platform’s 300MW gas turbine required a drive control solution that could withstand salt spray, high vibration, and 50A motor loads. Legacy cards failed every 18 months due to corrosion and power limitations, costing $120,000 in annual replacements and downtime. GE DS200SDCCG5AHD’s nickel-plated connectors and vibration-resistant locking lever extended service life to 60+ months, cutting replacement costs by 75%. Its high-power handling also supported a 15% turbine load increase during peak production, generating an additional $360,000 in monthly revenue. The platform’s engineering lead commented, “This card redefined what we thought possible for reliability in our harsh environment.”

Related Product Combination Solutions

Maximize the performance of GE DS200SDCCG5AHD with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Synchronizes with DS200SDCCG5AHD to adjust drive parameters based on turbine load demands, ensuring seamless system integration.

DS200PCCAG5ACB: High-Power Connection Card – Distributes power from the main supply to DS200SDCCG5AHD, supporting its 50A output requirements with minimal voltage drop.

IS220PPRFH1A: Redundant Power Supply – Delivers stable 110V DC input to DS200SDCCG5AHD, ensuring consistent performance during grid fluctuations.

ToolboxST Software: GE Configuration Tool – Enables calibration of DS200SDCCG5AHD’s current limits and thermal thresholds, and logs harmonic data for predictive maintenance.

IS200RTBAG3AFB: High-Density Terminal Board – Provides rugged wiring connections between DS200SDCCG5AHD and high-current motors, reducing connection resistance.

DS200LDCCH1ANA: DC Control Board – Complements DS200SDCCG5AHD by managing auxiliary low-voltage drives, creating a complete drive control ecosystem.

GE 9T51B Motor Protection Relay: Works with DS200SDCCG5AHD to provide redundant overcurrent protection for critical turbine motors.

DS200SLCCG1ADC: LAN Communication Card – Transmits DS200SDCCG5AHD’s real-time drive data to SCADA systems for centralized monitoring.

DS200SDCCG5AHD

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCCG5AHD is designed for minimal turbine downtime. First, power off the Mark V high-power rack and verify zero voltage in the target slot. Align the card with the “High-Power Drive” guide rails, slide it into place, and engage the locking lever to secure it—no specialized tools required. Connect the 110V DC input (from IS220PPRFH1A) and motor output leads (via IS200RTBAG3AFB terminals). Commissioning takes 30 minutes: use ToolboxST to set current limits (default 50A) and verify communication with the Mark V CPU via the 7-segment display. The card’s compact design fits existing high-power racks without modifications.

Routine maintenance is streamlined by advanced diagnostics. Weekly checks involve verifying the green power LED and 7-segment display (showing “00” for normal operation; error codes like “E3” indicate overload). Every 6 months, inspect the heat sink for dust buildup (critical in coal plants) and torque motor connections to prevent resistance-induced heating. If replacement is needed, the card is hot-swappable in redundant systems—swap it in 20 minutes while the turbine runs, with the CPU restoring all settings automatically.

GE backs DS200SDCCG5AHD with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for current calibration, harmonic analysis interpretation, and integration with legacy Mark V modules. GE maintains a global spare parts inventory, ensuring DS200SDCCG5AHD replacements ship within 48 hours for critical applications. For high-power retrofits, GE engineers offer on-site support to validate power distribution and thermal management.

Contact us today to upgrade your Mark V system’s high-power drive control with DS200SDCCG5AHD. Its robust power handling, predictive diagnostics, and rugged design will eliminate overload failures, reduce downtime, and maximize turbine performance—whether in large power plants, offshore platforms, or heavy industrial facilities.