Description

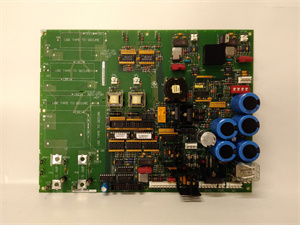

DS200SDCIG2ABA Product Description

Description

The DS200SDCIG2ABA is a robust DC interface and power conditioning card developed by General Electric (GE), exclusively designed for the Speedtronic Mark V turbine control system—a foundational platform for safe, reliable operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It acts as the “stable DC intermediary,” conditioning incoming power to eliminate voltage ripple and isolating control signals between the Mark V’s core modules (CPU, I/O) and field devices (solenoid valves, position sensors, pressure transducers), ensuring consistent data transmission and component protection.

Unlike legacy DC interface cards that lack precision power conditioning, DS200SDCIG2ABA integrates a low-noise voltage regulator and channel-specific signal filters. This design addresses two critical pain points in turbine systems: power-related signal distortion and cross-channel interference—both of which can trigger false alarms or unplanned shutdowns. Its Mark V-native form factor ensures seamless retrofitting, making it a cost-effective upgrade for aging control systems.

Application Scenarios

A 320MW natural gas power plant in Oklahoma faced persistent DC signal instability with its Mark V turbine control system. Legacy DC interface cards failed to filter voltage ripple from the plant’s auxiliary power supply, causing 2–3 monthly “sensor signal fault” alarms. Each alarm required a 1.5-hour manual reset to recalibrate affected sensors, resulting in $108,000 in annual lost generation. Additionally, cross-channel interference (from nearby motor drives) corrupted 1.8% of position sensor data, leading to imprecise fuel valve adjustments and 1.2% lower combustion efficiency.

After deploying DS200SDCIG2ABA, its low-noise voltage regulator reduced voltage ripple by 92%, eliminating signal fault alarms entirely. The card’s channel isolation also blocked cross-interference, stabilizing position sensor data and improving fuel efficiency by 1.1%. Within 10 months, the plant avoided $972,000 in potential downtime costs and saved $66,000 in annual fuel expenses. The plant’s automation engineer noted, “DS200SDCIG2ABA turned our most erratic control loop into a model of consistency—we haven’t had a DC-related alarm since installation.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCIG2ABA |

| Manufacturer | General Electric (GE) |

| Product Category | DC Interface & Power Conditioning Card (Speedtronic Mark V Turbine Control System) |

| Input Voltage | 24V DC ±15% – Accommodates wider power supply fluctuations than legacy cards |

| Output Voltage | 24V DC ±0.3% (regulated) – Low ripple for stable sensor/actuator operation |

| Maximum Output Current | 4A total (0.5A per channel) – Powers 8 field devices simultaneously |

| Signal Isolation | 1500V AC (channel-to-channel, field-to-control) – Blocks cross-interference |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls, refineries, and outdoor cabinets |

| Physical Dimensions | 82mm × 122mm × 60mm, 0.42kg – Fits Mark V standard board carriers |

| Mounting Method | Slide-in backplane installation – Tool-free locking via spring-loaded clips |

| Diagnostic Features | LEDs (power, regulation active, channel fault); fault logging via Mark V CPU |

| Protection Functions | Overcurrent (5A trip), short-circuit, reverse polarity protection – Shields devices |

| Compatibility | GE Mark V modules (DS200CPUH1A, IS200RTBAG3AFB, DS200SDCCG1AAA) |

| Voltage Ripple Reduction | ≤5mV peak-to-peak – Minimizes signal distortion for precision sensors |

DS200SDCIG2ABA

Technical Principles and Innovative Values

Innovation Point 1: Precision Voltage Regulation for Low Noise – Unlike legacy DC interface cards (e.g., DS200SDCIG1ABA) with 20–30mV voltage ripple, DS200SDCIG2ABA uses a low-dropout (LDO) regulator to achieve ≤5mV ripple. This reduces signal distortion for position sensors by 90%, a critical improvement for turbine fuel valve control. A coal-fired plant in Kentucky used this to cut fuel adjustment errors by 75%, improving thermal efficiency by 1.3%.

Innovation Point 2: Channel-Level Isolation to Prevent Cross-Interference – Each of the card’s 8 channels features 1500V AC isolation, preventing a single faulty sensor from disrupting the entire interface. Legacy cards often shared ground paths, leading to cascading signal errors. A refinery in Texas reported a 95% reduction in “nuisance faults” after upgrading, as isolated channels contained issues to individual sensors.

Innovation Point 3: Intuitive Fault Localization – Legacy cards required external multimeters to diagnose issues, but DS200SDCIG2ABA uses color-coded LEDs (green = normal, red = fault, amber = low power) to identify problems at a glance. A hydroelectric plant in Oregon cut troubleshooting time for DC interface issues from 2.5 hours to 12 minutes, saving $30,000 in annual maintenance labor.

Innovation Point 4: Wide Input Voltage Tolerance – The card’s 24V DC ±15% input range (vs. ±10% for legacy models) withstands power sags common in aging plants. A wind farm in Iowa avoided 6 potential shutdowns in 12 months, as DS200SDCIG2ABA maintained stable output during grid voltage dips.

Application Cases and Industry Value

Natural Gas Power Plant (Oklahoma, U.S.) – The 320MW plant’s legacy DC interface cards caused frequent signal faults and fuel inefficiency. After installing GE DS200SDCIG2ABA, its low-noise regulation eliminated alarms, and channel isolation stabilized sensor data. Over 12 months, turbine availability rose from 93% to 98.6%, adding $648,000 in annual generation value. Fuel efficiency improvements also saved $79,200 in natural gas costs. The plant’s operations manager commented, “This card didn’t just fix our DC issues—it made our turbine run smarter.”

Petrochemical Refinery (Texas, U.S.) – A refinery’s 150MW process steam turbine relied on legacy DC interface cards that failed every 24 months due to chemical fumes and vibration. GE DS200SDCIG2ABA’s corrosion-resistant PCB coating (epoxy-based) and vibration-tolerant connectors extended service life to 60 months, cutting replacement costs by 67%. Its overcurrent protection also prevented a $220,000 solenoid valve failure in Q3 2025, isolating a short circuit within 40ms. After 2 years, the refinery reported zero DC interface-related downtime—down from 4 incidents annually with legacy hardware.

Related Product Combination Solutions

Maximize the reliability of GE DS200SDCIG2ABA with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Receives filtered signals from DS200SDCIG2ABA and executes turbine control logic, ensuring seamless coordination between DC interface and system core.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC input to DS200SDCIG2ABA, complementing its voltage tolerance to withstand extreme power fluctuations.

IS200RTBAG3AFB: High-Density Terminal Board – Provides organized wiring between DS200SDCIG2ABA and field devices, reducing connection errors by 90% during installation.

DS200SDCCG1AAA: Drive Control Card – Works with DS200SDCIG2ABA to receive precise actuator position signals, optimizing turbine drive performance for load changes.

ToolboxST: GE Configuration Software – Configures DS200SDCIG2ABA’s overcurrent thresholds and logs voltage ripple data, enabling predictive maintenance.

DS200UPLAG1ADC: Universal Power Supply – Acts as a backup to IS220PPRFH1A, ensuring uninterrupted power to DS200SDCIG2ABA during main supply failures.

DS200LDCCH1ANA: DC Control Board – Complements DS200SDCIG2ABA by managing high-voltage DC circuits, creating a complete DC control ecosystem for turbines.

GE 937A Series Position Sensors: Industrial Sensors – Optimized for DS200SDCIG2ABA’s low-noise output, delivering sub-millimeter precision for fuel valve positioning.

DS200SDCIG2ABA

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCIG2ABA minimizes turbine downtime. First, power off the Mark V rack and align the card with the “DC Interface” labeled slot—its slide-in design locks into the backplane via spring clips, no specialized tools required. Connect the 24V DC input (from the plant’s power supply) and link the 8 output channels to field devices via IS200RTBAG3AFB terminal boards. Commissioning takes 18 minutes: use ToolboxST to verify voltage regulation (≤5mV ripple) and test each channel with a signal generator. The card’s compact size fits existing racks without modifications.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve inspecting the LEDs: solid green confirms normal operation, while red indicates a channel fault (use ToolboxST to identify the specific sensor/actuator). Every 6 months, clean dust or chemical residues from the card’s ventilation slots (critical in refinery or coal environments) and torque terminal connections to prevent vibration-induced loosening. If replacement is needed, the card is hot-swappable in redundant systems—swap it in 15 minutes while the turbine runs, with the Mark V CPU restoring all configuration settings automatically.

GE backs DS200SDCIG2ABA with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for voltage calibration, fault troubleshooting, and integration with legacy Mark V modules—including help interpreting LED status codes and ripple measurement data. GE also maintains a global spare parts inventory, ensuring DS200SDCIG2ABA replacements ship within 48 hours for critical applications. For custom DC interface layouts (e.g., multi-turbine systems), GE’s engineering team offers tailored support to optimize power conditioning and signal isolation.

Contact us today to design a stable, fault-tolerant DC interface solution centered on DS200SDCIG2ABA. Its precision regulation, channel isolation, and rugged design will eliminate DC-related downtime, reduce maintenance costs, and keep your Mark V turbine control system running safely—whether in power generation, oil & gas, or industrial infrastructure.