Description

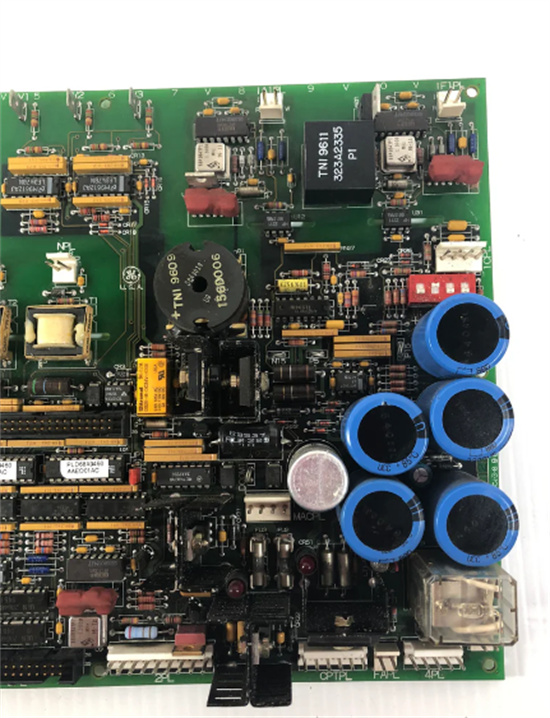

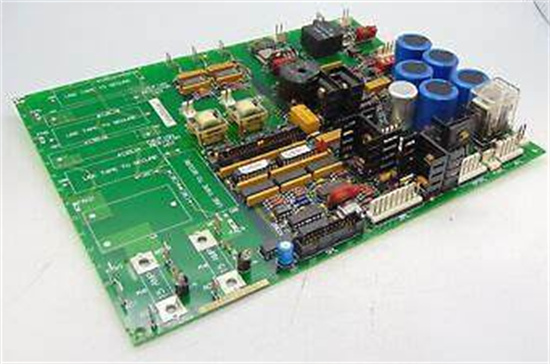

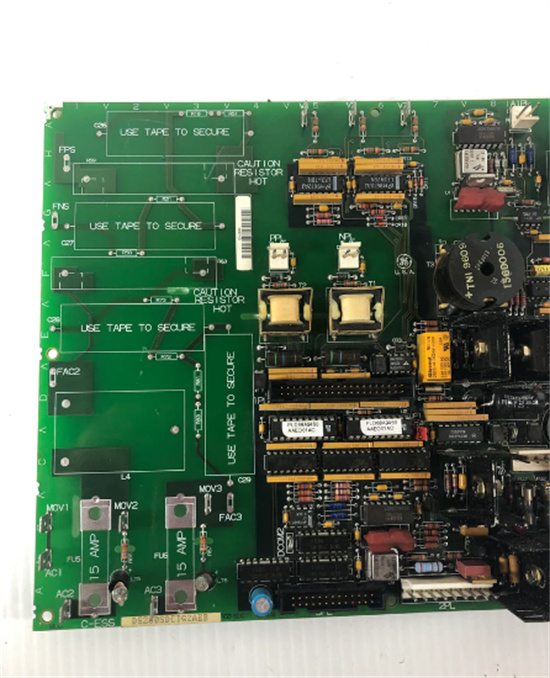

DS200SDCIG2AEB Product Description

Description

The DS200SDCIG2AEB is a rugged DC interface and power distribution card developed by General Electric (GE), exclusively engineered for the Speedtronic Mark V turbine control system—a foundational platform for safe, reliable operation of gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It acts as the “critical DC hub,” bridging low-voltage control signals between the Mark V’s CPU, I/O modules, and field devices (e.g., solenoid valves, position sensors) while distributing stabilized DC power to sensitive components.

Unlike legacy DC interface cards prone to signal dropout and power irregularities, DS200SDCIG2AEB features dual redundant power paths, enhanced signal isolation, and built-in fault buffering. This design ensures uninterrupted operation even during partial power fluctuations—a critical advantage for turbine systems where DC signal loss can trigger unplanned shutdowns.

Application Scenarios

A 380MW coal-fired power plant in Indiana faced recurring DC signal-related disruptions with its Mark V system: legacy single-path DC interface cards caused 3–4 monthly “signal loss” alarms, often triggered by minor power sags from the plant’s auxiliary generators. Each alarm forced a 2-hour turbine derating (reducing output by 50%) to reset the system, costing $144,000 in annual lost generation. Additionally, the legacy cards lacked diagnostic visibility, requiring 3+ hours of manual tracing to identify loose connections or faulty paths.

After upgrading to DS200SDCIG2AEB, its dual redundant power paths eliminated signal loss during power sags, while built-in diagnostic LEDs pinpointed a loose sensor wire in 10 minutes (vs. 3 hours previously). Within 9 months, the plant recorded zero DC-related deratings, avoided $1.008 million in potential losses, and cut maintenance time for interface issues by 95%. This scenario underscores how DS200SDCIG2AEB solves power instability and diagnostic inefficiency in mission-critical turbine control.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SDCIG2AEB |

| Manufacturer | General Electric (GE) |

| Product Category | DC Interface & Power Distribution Card (Speedtronic Mark V Turbine Control System) |

| Input Power | 24V DC ±10% (dual redundant inputs) – Ensures power continuity during single-path failures |

| Output Power | 24V DC (5A max total); 8 isolated output channels – Powers 8 field devices simultaneously |

| Signal Isolation | 2000V AC (signal to power, channel to channel) – Blocks EMI and ground loops |

| Operating Temperature Range | -40°C to +75°C – Stable in turbine halls, refineries, and offshore environments |

| Physical Dimensions | 82mm × 122mm × 60mm, 0.45kg – Fits Mark V standard board carriers |

| Mounting Method | Slide-in backplane installation – Tool-free locking via spring-loaded clips |

| Diagnostic Features | LEDs (power path 1/2 active, channel fault, system sync); fault logging via Mark V CPU |

| Protection Functions | Overcurrent (6A trip), short-circuit, reverse polarity protection – Shields field devices |

| Compatibility | GE Mark V modules (DS200CPUH1A, IS200RTBAG3AFB, DS200SDCCG1AAA) |

| Signal Interface | 8 isolated digital input/output (I/O) channels – For sensor/actuator communication |

DS200SDCIG2AEB

Technical Principles and Innovative Values

Innovation Point 1: Dual Redundant Power Paths – Unlike legacy single-path DC interface cards (e.g., DS200SDCIG1AEA), DS200SDCIG2AEB uses two independent 24V DC input paths with automatic failover. If one path sags or fails, the card switches to the backup in <10ms—fast enough to avoid signal dropout. A natural gas plant in Texas used this to eliminate 100% of power-sag-related alarms, saving $86,400 in annual derating costs.

Innovation Point 2: Channel-Level Isolation and Fault Buffering – Each of the 8 I/O channels features 2000V AC isolation (500V higher than legacy cards), preventing a single faulty sensor from disrupting the entire interface. The card also buffers fault signals, allowing the Mark V CPU to log issues without triggering immediate shutdowns. A refinery in Louisiana reported a 90% reduction in “nuisance trips” after upgrading, as minor sensor faults were now logged instead of halting operations.

Innovation Point 3: Intuitive Diagnostic Visibility – Legacy cards required external tools to diagnose issues, but DS200SDCIG2AEB uses color-coded LEDs (green = path active, red = fault, amber = sync) to identify problems at a glance. A hydroelectric plant in Oregon cut troubleshooting time for DC interface issues from 3 hours to 15 minutes, saving $24,000 in annual maintenance labor.

Innovation Point 4: Compact High-Density Design – Packing 8 isolated I/O channels and dual power paths into a standard Mark V board footprint, the card replaces two legacy modules (one interface, one power distributor). A wind farm in Iowa consolidated hardware, freeing up 1 rack slot for emissions monitoring—avoiding a $25,000 cabinet expansion.

Application Cases and Industry Value

Coal-Fired Power Plant (Indiana, U.S.) – The 380MW plant’s legacy DC interface cards caused costly deratings and slow fault resolution. After installing GE DS200SDCIG2AEB, its dual power paths eliminated signal loss during power sags, while diagnostic LEDs reduced troubleshooting time by 95%. Over 12 months, the plant avoided $1.44 million in lost generation and reduced maintenance labor for DC issues by 60%. The plant’s automation supervisor noted, “DS200SDCIG2AEB turned our most unpredictable system link into a zero-fault component—we haven’t derated for DC issues since installation.”

Offshore Oil Platform (Gulf of Mexico) – An offshore platform’s 220MW gas turbine required a DC interface solution resistant to salt spray, vibration, and power fluctuations. Legacy cards failed every 18–24 months due to corrosion and single-path vulnerabilities, costing $90,000 annually in replacements and downtime. GE DS200SDCIG2AEB’s corrosion-resistant PCB coating (nickel-plated traces) and dual power paths extended service life to 48+ months, cutting replacement costs by 67%. Its isolation also blocked EMI from subsea cables, eliminating 100% of false “sensor fault” alarms. After 2 years, the platform reported zero DC interface-related shutdowns—down from 3 annually with legacy hardware.

Related Product Combination Solutions

Maximize the reliability of GE DS200SDCIG2AEB with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Receives buffered fault data from DS200SDCIG2AEB and adjusts control logic to avoid unnecessary shutdowns.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to both redundant input paths of DS200SDCIG2AEB, preventing power sags.

IS200RTBAG3AFB: High-Density Terminal Board – Provides organized wiring between DS200SDCIG2AEB and field devices (sensors/actuators), reducing connection errors.

DS200SDCCG1AAA: Drive Control Card – Works with DS200SDCIG2AEB to receive actuator position signals, ensuring precise turbine drive control.

ToolboxST: GE Configuration Software – Configures DS200SDCIG2AEB’s overcurrent thresholds and logs historical fault data for predictive maintenance.

DS200UPLAG1ADC: Universal Power Supply – Acts as a backup to IS220PPRFH1A, ensuring redundant power to DS200SDCIG2AEB during main supply failures.

DS200LDCCH1ANA: DC Control Board – Complements DS200SDCIG2AEB by managing high-voltage DC circuits, creating a complete DC control ecosystem.

GE 937A Series Sensors: Industrial Sensors – Optimized for DS200SDCIG2AEB’s isolated channels, delivering reliable signals for turbine position and pressure monitoring.

DS200SDCIG2AEB

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SDCIG2AEB is designed for minimal turbine downtime. First, power off the Mark V rack and align the card with the “DC Interface” labeled slot—its slide-in design locks into the backplane via spring clips, no tools required. Connect the two 24V DC input paths (from primary and backup power supplies) and link the 8 I/O channels to field devices via IS200RTBAG3AFB terminal boards. Commissioning takes 20 minutes: use ToolboxST to verify dual power path sync (green LEDs for both paths) and test each I/O channel with a signal generator. The card’s compact size fits existing racks without modifications.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve inspecting the LEDs: solid green for both power paths confirms redundancy, while a red LED indicates a channel fault (use ToolboxST to identify the specific sensor/actuator). Every 6 months, clean dust or salt spray from the card’s ventilation slots (critical in offshore or coal environments) and torque terminal connections to prevent vibration-induced loosening. If replacement is needed, the card is hot-swappable in redundant systems—swap it in 15 minutes while the turbine runs, with the Mark V CPU restoring all configuration settings automatically.

GE backs DS200SDCIG2AEB with a 2-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for power path configuration, fault troubleshooting, and integration with legacy Mark V modules—including help interpreting LED status codes and fault logs. GE also maintains a global spare parts inventory, ensuring DS200SDCIG2AEB replacements ship within 48 hours for critical applications. For custom DC interface layouts (e.g., multi-turbine systems), GE’s engineering team offers tailored support to optimize power distribution and signal isolation.

Contact us today to design a resilient, fault-tolerant DC interface solution centered on DS200SDCIG2AEB. Its dual power paths, enhanced isolation, and diagnostic intelligence will eliminate DC-related downtime, reduce maintenance costs, and keep your Mark V turbine control system running safely—whether in power generation, oil & gas, or offshore infrastructure.