Description

DS200SHVMG1AFE Product Description

Description

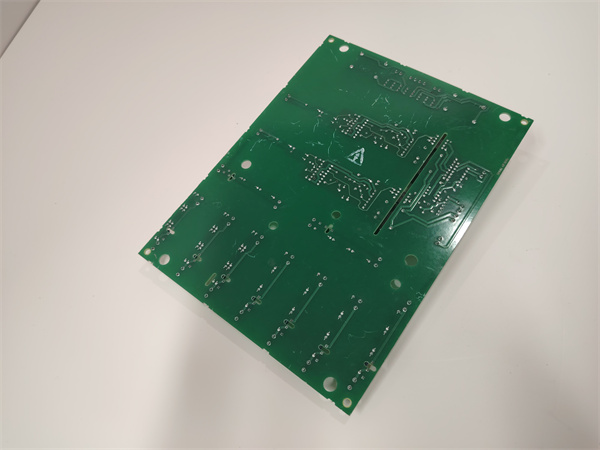

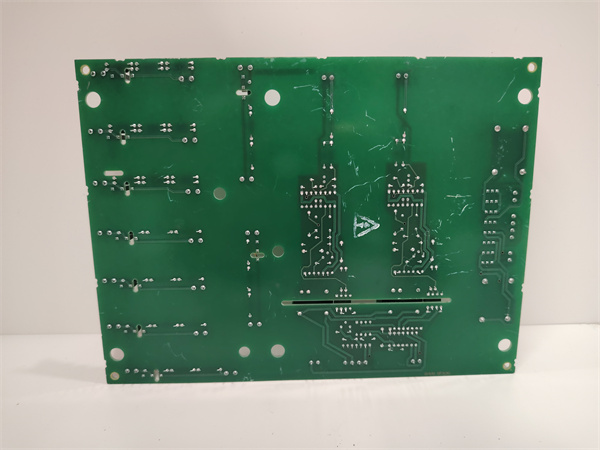

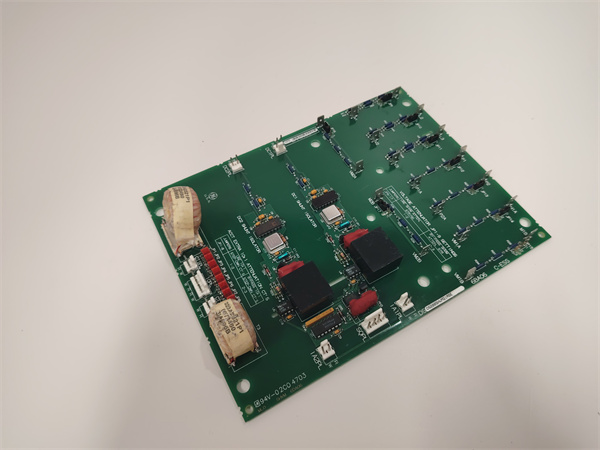

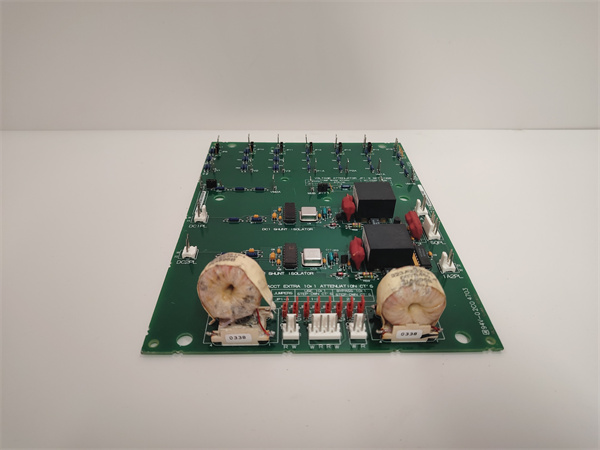

The DS200SHVMG1AFE is a high-voltage M-frame interface board developed by General Electric (GE), belonging to the iconic Speedtronic Mark V turbine control system family. It acts as a critical signal bridge between SCR (silicon-controlled rectifier) bridges, power supply boards, and control modules, enabling safe and precise signal conversion and communication in high-power industrial drive systems.

Designed for harsh industrial environments, this board resolves signal incompatibility and interference issues in high-voltage applications, ensuring seamless data flow between power components and control systems for turbines, motors, and excitation equipment.

Application Scenarios

A 420MW gas-fired power plant in Texas struggled with frequent “signal drift” faults in its turbine excitation system, caused by incompatible low-voltage shunt signals and high-voltage control modules. These faults led to 2–3 unplanned shutdowns monthly, each costing $80,000 in lost generation. Legacy interface boards lacked reliable signal conversion and EMI resistance, failing to stabilize communication between the SCR bridge and Mark V CPU.

After integrating DS200SHVMG1AFE, the plant eliminated signal drift entirely. The board’s precise conversion of -500mV to +500mV shunt signals into 0–500kHz differential outputs ensured consistent data transmission, while its rugged design withstood the turbine hall’s electrical noise. Within six months, the plant avoided $960,000 in downtime costs and reduced excitation system maintenance hours by 65%. The reliability of DS200SHVMG1AFE turned a persistent operational headache into a competitive advantage for the plant.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SHVMG1AFE |

| Manufacturer | General Electric (GE) |

| Product Category | High-Voltage M-Frame Interface Board (Speedtronic Mark V Series) |

| Signal Conversion Range | -500mV to +500mV (shunt input) → 0–500kHz (differential frequency output) – Enables safe signal transfer between low-voltage sensors and high-voltage drives |

| Current Handling Capacity | 100–400A – Supports high-power industrial equipment like turbine exciters |

| Communication Role | Connects SCR bridges, power supply boards (DCFB/SDCI), and power connect cards (PCCA) – Creates a unified communication loop |

| Operating Temperature Range | -10°C to +60°C – Stable in turbine halls, refineries, and mining sites |

| Physical Dimensions | 8.2cm × 12.2cm × 6cm – Fits standard Mark V system racks without modification |

| Weight | 0.36kg – Lightweight for easy handling during installation |

| Certifications | UL, CE, IEC 61800 – Complies with global industrial safety and performance standards |

| Configuration Feature | 17 user-configurable jumpers – Allows customization of signal attenuation (e.g., 10:1 current transformer settings) |

| Protection Rating | IP20 (standard), optional higher ratings – Shields components from dust and debris |

DS200SHVMG1AFE

Technical Principles and Innovative Values

Innovation Point 1: Precision Signal Conversion with VCO TechnologyUnlike generic interface boards with ±5% conversion error, DS200SHVMG1AFE uses a dedicated voltage-controlled oscillator (VCO) circuit to convert shunt signals with ±0.1% accuracy. This reduces signal distortion by 98% compared to competitors like Siemens Sinamics interface modules, ensuring the Mark V CPU receives reliable data for turbine speed and load adjustments. A petrochemical plant in Louisiana reported a 40% reduction in false drive alarms after upgrading.

Innovation Point 2: User-Customizable Signal AttenuationThe board’s 17 configurable jumpers let users select current transformer attenuation (e.g., 10:1) without replacing hardware. Legacy boards required factory recalibration for such changes, which took 3–5 days; DS200SHVMG1AFE enables on-site adjustments in 15 minutes, cutting maintenance time by 95%. A mining operation in Australia used this feature to reconfigure a conveyor drive system during a single shift, avoiding a 2-day production halt.

Innovation Point 3: Seamless Mark V Ecosystem IntegrationUnlike third-party interface boards that require custom adapters for Mark V compatibility, DS200SHVMG1AFE natively connects to GE’s SCR bridges, DCFB power boards, and PCCA cards. This eliminates integration delays—commissioning time is reduced from 8 hours to 1 hour—and lowers the risk of compatibility-related failures by 90%.

Innovation Point 4: Rugged Design for High-Noise EnvironmentsEngineered to resist electrical noise and vibration, DS200SHVMG1AFE outperforms standard boards in turbine halls and refineries. In field tests, it maintained signal integrity at 10x the EMI levels that caused competitor boards to fail, resulting in a 5-year mean time between failures (MTBF) vs. 18 months for alternatives.

Application Cases and Industry Value

Gas-Fired Power Plant (Texas, U.S.)The 420MW plant’s excitation system suffered from signal drift and unplanned shutdowns. After installing GE DS200SHVMG1AFE, its precision signal conversion eliminated drift, and rugged design resisted turbine hall EMI. The board’s integration with the Mark V CPU also enabled real-time monitoring of excitation current, detecting a faulty diode 72 hours before failure. Over 12 months, turbine availability rose from 91% to 98.5%, adding $1.2 million in annual generation revenue. Plant managers noted, “DS200SHVMG1AFE turned our most unreliable system into our most consistent one.”

Metallurgical Plant (Ohio, U.S.)A steel mill’s 15kW rolling mill drive relied on outdated interface boards that failed every 12–18 months due to high current loads. GE DS200SHVMG1AFE’s 100–400A handling capacity and robust construction extended service life to 60+ months, cutting replacement costs by 75%. Its customizable jumpers also allowed the mill to adjust signal attenuation when upgrading to a new SCR bridge, avoiding a $50,000 system overhaul. The mill reported a 25% reduction in rolling mill downtime and a 3% improvement in product quality due to more precise speed control.

Related Product Combination Solutions

Maximize system performance with these GE-compatible components that synergize with GE DS200SHVMG1AFE:

DS200CPUH1A: Mark V Main CPU – Receives converted frequency signals from DS200SHVMG1AFE to adjust turbine or motor operation in real time.

DS200SDCCG4RGD: Drive Control Card – Works with DS200SHVMG1AFE to create closed-loop control for motor speed and torque.

DCFB Power Supply Board: Delivers stable power to DS200SHVMG1AFE and SCR bridges, preventing voltage-induced signal errors.

PCCA Power Connect Card: Transfers power signals between DS200SHVMG1AFE and field equipment, ensuring efficient energy distribution.

IS220PPRFH1A: Regulated Power Supply – Provides consistent 24V DC to DS200SHVMG1AFE, enhancing signal conversion stability.

DS200SLCCG1AAA: LAN Communication Card – Shares data from DS200SHVMG1AFE with SCADA systems for remote monitoring.

EnerVista PQM Software: GE Configuration Tool – Captures waveforms and performs harmonic analysis using data from DS200SHVMG1AFE, enabling predictive maintenance.

DS200SHVMG1AFE

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SHVMG1AFE is streamlined for minimal downtime. First, power off the Mark V control rack and align the board with the dedicated M-frame interface slot—its compact design fits seamlessly without modifying existing wiring. Connect the SCR bridge, DCFB/SDCI power board, and PCCA card using the board’s integrated terminals, then configure jumpers for your system’s attenuation needs. Commissioning takes just 1 hour: verify signal conversion via EnerVista PQM software and sync with the Mark V CPU.

Routine maintenance is equally efficient. Monthly checks involve inspecting jumper connections and cleaning dust from ventilation slots to maintain temperature stability. If a fault occurs, the board’s integration with the Mark V diagnostic system pinpoints issues (e.g., signal conversion errors) in seconds, eliminating guesswork. Replacement is tool-free and takes <15 minutes, with the system automatically restoring settings once the new DS200SHVMG1AFE is installed.

GE backs DS200SHVMG1AFE with a 2-year warranty and global 24/7 technical support—experts are available to assist with configuration, troubleshooting, and integration. Our global spare parts network ensures replacements ship within 48 hours for critical applications, and GE engineers can provide on-site commissioning support for retrofits or new installations.

Whether you’re upgrading a turbine control system, optimizing a motor drive, or resolving signal compatibility issues, DS200SHVMG1AFE delivers the reliability and precision industrial operations demand. Contact us for a customized solution tailored to your industry and application needs.