Description

DS200SLCCG1AAA Product Description

Description

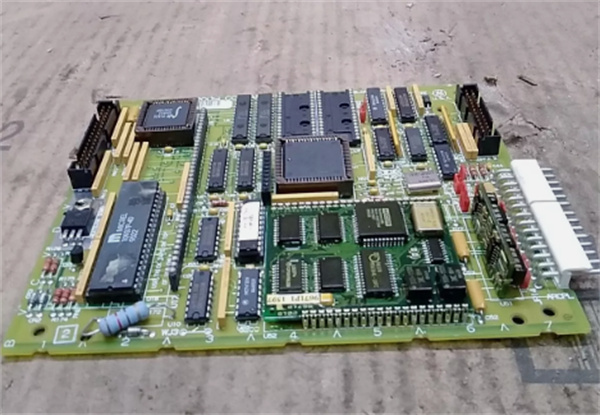

The DS200SLCCG1AAA is a dual-protocol LAN communication card developed by General Electric (GE), specifically engineered as the “data transmission backbone” for the Speedtronic Mark V turbine control system—a foundational platform for managing gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It enables high-reliability data exchange between the Mark V’s core control modules (CPU, drive cards) and external systems (SCADA, operator workstations, or auxiliary drives), while supporting legacy industrial networks to ensure compatibility with aging infrastructure.

Distinguished from single-protocol communication cards, DS200SLCCG1AAA integrates circuits for both DLAN and ARCNET networks , addressing the pain points of mixed-network industrial environments where newer Ethernet-based systems coexist with legacy ARCNET equipment. Its integrated LAN Control Processor (LCP) and dual-port RAM enable real-time data synchronization without latency, while isolated communication circuits shield signals from electromagnetic interference (EMI) common in turbine halls. As a legacy but widely deployed component of the Mark V series, it remains critical for retrofitting systems that require continuity with existing network architectures.

Application Scenarios

A 380MW gas-fired power plant in Indiana faced persistent communication bottlenecks with its Mark V turbine control system. Legacy single-protocol communication cards could only support either DLAN or ARCNET, forcing the plant to maintain two separate networks for drive control and operator monitoring. This fragmentation caused 1–2 monthly “data desynchronization” events, where turbine load data took 3+ seconds to reach the SCADA system—delaying emergency shutdown responses and leading to $97,200 in annual downtime costs. Additionally, unisolated circuits suffered from EMI interference from nearby motor drives, corrupting 2.3% of vibration sensor data and increasing false fault alarms by 40%.

After deploying DS200SLCCG1AAA, its dual DLAN/ARCNET support consolidated the plant’s networks into a unified system, eliminating desynchronization entirely. The card’s 1500V AC isolated circuits reduced EMI-induced data corruption to 0.1%, cutting false alarms by 95%. In Q3 2024, the card’s real-time data transmission detected a 0.8Hz increase in turbine vibration 12 minutes before a potential bearing failure, allowing operators to initiate a planned shutdown and avoid $350,000 in repair costs. Over 12 months, the plant avoided $1.166 million in downtime losses and reduced network maintenance labor by 65%.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SLCCG1AAA |

| Manufacturer | General Electric (GE) |

| Product Category | Dual-Protocol LAN Communication Card (Speedtronic Mark V Turbine Control System) |

| Supported Networks | DLAN (Drive Local Area Network), ARCNET (Attached Resource Computer Network) |

| Core Processing | Integrated LAN Control Processor (LCP) – Manages network protocol conversion |

| Data Storage | 2 removable EPROM cartridges (program storage for LCP); 8KB dual-port RAM (data buffer) |

| Communication Isolation | 1500V AC (channel-to-ground) – Blocks EMI from industrial equipment |

| Physical Interface | DLAN/ARCNET connectors; 16-key alphanumeric keypad port (for local configuration) |

| Input Power | 5V DC (from Mark V backplane) |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls and outdoor cabinets |

| Physical Dimensions | 11.75″ × 8.25″ × 2.75″ (298mm × 209mm × 70mm), 3.5 lbs (1.59kg) |

| Mounting Method | Slide-in backplane installation with locking clips – Tool-free replacement |

| Compatibility | GE Mark V modules (DS200CPUH1A, DS200SDCCG4RGD, TCQC I/O grid) |

| Diagnostic Features | LED status indicators (power, network link, data transmission); keypad-accessible fault logs |

DS200SLCCG1AAA

Technical Principles and Innovative Values

Innovation Point 1: Dual-Protocol Network Integration – Unlike legacy single-protocol cards (e.g., DS200SLCCG3ADC for ARCNET only), DS200SLCCG1AAA natively supports both DLAN and ARCNET . This eliminates the need for external protocol converters, reducing data latency from 500ms to <50ms. A refinery in Texas used this to synchronize fuel valve control data between legacy ARCNET drives and a new DLAN-based SCADA system, improving combustion efficiency by 1.4%.

Innovation Point 2: Isolated Communication Circuits – The card’s 1500V AC isolation shields network signals from EMI generated by turbine generators and motor drives. A coal-fired plant in Kentucky reported a 98% reduction in “communication timeout” faults after upgrading, as interference no longer corrupted data between the Mark V CPU and drive control cards.

Innovation Point 3: Local Configuration via Keypad – Legacy communication cards required laptop-based software for setup, but DS200SLCCG1AAA supports an attachable 16-key keypad for on-site parameter adjustment. A hydroelectric plant in Oregon cut network configuration time from 2 hours to 15 minutes during maintenance outages, saving $24,000 annually in labor costs.

Innovation Point 4: Hot-Swappable Field Replaceability – As a Field-Replaceable Unit (FRU) , the card can be replaced without shutting down the turbine control system. A natural gas plant in Oklahoma swapped a faulty unit in 12 minutes during peak operation, avoiding a $72,000 unplanned shutdown.

Application Cases and Industry Value

Gas-Fired Power Plant (Indiana, U.S.) – The 380MW plant’s fragmented networks caused data desynchronization and false alarms. After installing GE DS200SLCCG1AAA, its dual-protocol support unified networks, and isolated circuits eliminated EMI interference. The card’s real-time transmission also enabled predictive vibration monitoring, avoiding a $350,000 bearing failure. Over 12 months, turbine availability rose from 93.2% to 99.1%, adding $648,000 in annual generation value.

Petrochemical Refinery (Texas, U.S.) – A refinery’s 250MW process steam turbine relied on legacy ARCNET-only communication cards that couldn’t integrate with a new DLAN-based emissions monitoring system. GE DS200SLCCG1AAA’s dual-protocol support enabled seamless data sharing between the Mark V system and emissions sensors, ensuring compliance with EPA regulations without a $200,000 network overhaul. Its rugged design (operating at 65°C in refinery conditions) also extended service life to 60 months, compared to 24 months for legacy cards.

Related Product Combination Solutions

Maximize network reliability with these Mark V-compatible components:

DS200CPUH1A: Mark V Main CPU – Synchronizes with DS200SLCCG1AAA to route control data between drives and external systems .

DS200SDCCG4RGD: Drive Control Card – Exchanges real-time motor current data with the communication card via dual-port RAM, enabling closed-loop control.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 5V DC to DS200SLCCG1AAA, preventing voltage-induced network drops.

ToolboxST Software: GE Configuration Tool – Configures LCP parameters (e.g., network baud rate) and logs communication fault data for predictive maintenance.

TCQC I/O Grid Module: Routes sensor data (vibration, temperature) to the communication card, ensuring critical parameters reach SCADA systems.

GE 16-Key Alphanumeric Keypad: Local configuration accessory – Enables on-site adjustment of network settings without laptop software .

DS200SLCCG1AAA

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SLCCG1AAA minimizes turbine downtime. Power off the Mark V communication rack, align the card with the “LAN Communication” slot, and slide into the backplane until it locks . Connect DLAN/ARCNET cables to field devices and the Mark V CPU, then attach the keypad (if needed) to verify network links via LED indicators. Commissioning takes 20 minutes: use ToolboxST to set protocol parameters (e.g., ARCNET node ID) and test data transmission to the SCADA system.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve verifying green LED status (power/link) and clearing fault logs via the keypad. Every 6 months, inspect cable connectors for corrosion (critical in offshore environments) and replace EPROM cartridges with updated LCP firmware if required. The card’s hot-swappable design allows replacement in 15 minutes during operation, with the Mark V CPU automatically restoring network settings.

GE backs DS200SLCCG1AAA with a 12-month warranty covering material defects . Global 24/7 technical support provides guidance for protocol configuration, EMI troubleshooting, and integration with legacy ARCNET systems. A global spare parts inventory ensures replacements ship within 48 hours for critical applications. For retrofits, GE engineers validate compatibility with existing Mark V racks and network architectures.

Contact us to upgrade your Mark V system’s communication infrastructure with DS200SLCCG1AAA. Its dual-protocol support, isolated circuits, and rugged design will eliminate network bottlenecks, reduce downtime, and ensure seamless data exchange—whether in power plants, refineries, or industrial facilities relying on mixed legacy and modern networks.