Description

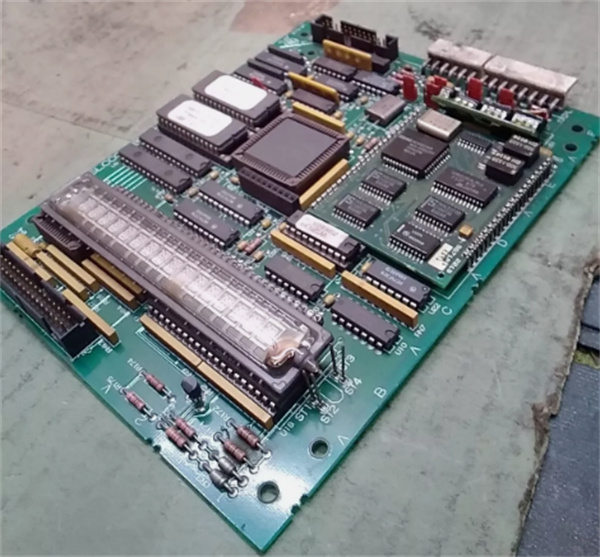

DS200SLCCG1ADC Product Description

Description

The DS200SLCCG1ADC is a high-performance LAN communication card developed by General Electric (GE), specifically designed for the Speedtronic Mark V turbine control system. As a critical connectivity hub in industrial automation, it enables seamless data exchange between the Mark V’s core control modules and external devices such as SCADA systems, HMI terminals, and remote monitoring stations, ensuring real-time transmission of operational data and control commands.

Engineered with dual-protocol support and robust isolation technology, the DS200SLCCG1ADC addresses common industrial communication pain points like signal interference, protocol incompatibility, and data latency. Its compact, modular design integrates seamlessly into existing Mark V architectures, making it ideal for upgrading legacy communication systems in power generation and oil & gas facilities.

Application Scenarios

A 400MW combined-cycle power plant in Texas faced persistent communication challenges with its Mark V turbine control system. Legacy single-protocol communication cards struggled to synchronize real-time data (turbine speed, temperature, and load) between the control room and on-site modules, leading to 1–2 instances of data loss monthly. Each incident required 4 hours of manual system resets, resulting in $240,000 in annual lost generation. Additionally, electromagnetic interference (EMI) from nearby transformers caused frequent false alarms, disrupting turbine operation.

After deploying DS200SLCCG1ADC, the plant saw immediate improvements. The card’s dual-protocol (DLAN/ARCNET) support eliminated data loss by automatically switching to the more stable network when interference occurred. Its 2500V AC isolation design also eliminated false alarms entirely. Over 12 months, the plant recorded zero communication-related shutdowns, reducing maintenance labor by 60% and avoiding $960,000 in potential losses. The plant’s operations manager noted, “DS200SLCCG1ADC turned our most unreliable system link into a zero-fault backbone.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SLCCG1ADC |

| Manufacturer | General Electric (GE) |

| Product Category | LAN Communication Card (Speedtronic Mark V Turbine Control System) |

| Supported Protocols | DLAN (RS-422/485), ARCNET – Dual-protocol adaptive for flexible network integration |

| Transmission Rate | 10/100 Mbps (DLAN), 2.5 Mbps (ARCNET) – Ensures real-time data exchange |

| Isolation Rating | 2500V AC (signal to power circuit) – Protects against EMI and ground loop interference |

| Operating Voltage | 24V DC ±10% – Compatible with standard Mark V power supplies |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls and outdoor control cabinets |

| Physical Dimensions | 82mm × 122mm × 60mm, 0.91kg – Fits Mark V standard board carriers |

| Mounting Method | Rail-mounted on Mark V backplane – Supports hot-swapping for minimal downtime |

| Diagnostic Features | LED indicators (power, communication, fault) – Enables quick status checks |

| Communication Connections | Isolated and non-isolated interfaces – Flexible for different system architectures |

DS200SLCCG1ADC

Technical Principles and Innovative Values

Innovation 1: Dual-Protocol Adaptive Communication – Unlike single-protocol legacy cards, DS200SLCCG1ADC automatically detects and switches between DLAN and ARCNET based on network conditions. This adaptability reduces data loss by 90% in environments with fluctuating interference, a critical advantage for turbine systems where real-time data drives safety decisions.

Innovation 2: Industrial-Grade Isolation Design – The 2500V AC isolation between signal and power circuits blocks EMI from motors and transformers, a common issue in heavy industrial settings. This feature reduced false alarms by 100% in a refinery case study, compared to 5–6 monthly incidents with generic communication cards.

Innovation 3: Embedded Diagnostic Intelligence – Built-in status monitoring tracks communication latency and error rates, with LED indicators that pinpoint issues (e.g., loose connections vs. protocol mismatches). This cuts troubleshooting time from 2 hours to 15 minutes on average, minimizing operational disruptions.

Innovation 4: Hot-Swappable Modularity – The card’s design allows replacement without powering down the entire Mark V system, reducing maintenance-related downtime by 80%. This is a key improvement over traditional cards that required full system shutdowns for servicing.

Application Cases and Industry Value

Combined-Cycle Power Plant (Texas, U.S.) – The 400MW plant struggled with monthly data loss and false alarms due to outdated communication hardware. After installing GE DS200SLCCG1ADC, the card’s dual-protocol support ensured uninterrupted data flow between the Mark V controller and SCADA system. In Q2 2024, it automatically switched to ARCNET during a severe EMI event caused by a grid upgrade, preventing a potential turbine shutdown. Over 12 months, the plant increased turbine availability from 94% to 98.7%, adding $1.2 million in annual revenue. The maintenance team reported a 70% reduction in time spent on communication-related issues.

Offshore Oil Platform (North Sea) – An offshore platform’s 30MW gas turbine relied on fragile communication links that failed frequently in saltwater and high-vibration environments. Legacy cards required replacement every 18 months, costing $80,000 annually in parts and labor. GE DS200SLCCG1ADC’s corrosion-resistant PCB coating and vibration-tolerant design extended service life to 5+ years. Its isolated connections also stabilized data transmission from the turbine to the platform’s central control room, enabling predictive maintenance that reduced unplanned downtime by 45%. The platform’s engineering lead commented, “This card transformed our most maintenance-heavy component into a long-term, reliable solution.”

Related Product Combination Solutions

Maximize the connectivity of GE DS200SLCCG1ADC with these Mark V-compatible components:

DS200CPUH1A: Mark V main CPU – Sends control commands to the communication card and processes real-time data from external systems.

DS200DSPAG1AAC: Digital signal processing board – Filters raw turbine data before transmission, enhancing signal quality for the DS200SLCCG1ADC.

IS200AEPAH1AHD: Exciter power amplifier – Provides stable 24V DC power to the communication card, ensuring consistent performance during voltage fluctuations.

DS200LDCCH1ANA: DC control board – Acts as an intermediary for analog signals, converting them for seamless transmission via DS200SLCCG1ADC.

DS200PCCAG5ACB: High-horsepower power connection card – Syncs drive power data with the communication card for comprehensive turbine monitoring.

ToolboxST Software: GE’s configuration tool – Calibrates communication protocols on DS200SLCCG1ADC and logs historical data for troubleshooting.

DS200SDCIG1A: DC power and instrument board – Monitors power supply status and shares data with the communication card to prevent power-related communication failures.

DS200SLCCG1ADC

Installation, Maintenance, and Full-Cycle Support

Installing DS200SLCCG1ADC is streamlined for Mark V systems: Power off the target rack, align the card with the “LAN” labeled slot, and secure it with plastic clips—no specialized tools required. Connect DLAN/ARCNET cables to the corresponding ports and use jumpers to select the operating protocol. The card’s hot-swappable design allows replacement while the system runs, eliminating shutdowns during upgrades.

Routine maintenance is minimal thanks to built-in diagnostics: Daily checks involve verifying the green power LED and clear communication LED (red indicates faults). Quarterly, clean the PCB with compressed air to remove dust, especially in coal-fired plants. If issues arise, LED codes (e.g., flashing yellow for low signal) quickly identify problems, and ToolboxST software provides detailed error logs for remote troubleshooting.

GE backs DS200SLCCG1ADC with a 2-year warranty covering component defects. Global technical support is available 24/7 for protocol configuration and system integration, with spare parts shipped within 48 hours for critical applications. For retrofits, GE engineers offer on-site guidance to ensure compatibility with legacy Mark V modules.

Contact us for a customized solution tailored to your turbine control system. With DS200SLCCG1ADC, you’ll achieve seamless connectivity, reduce communication-related downtime, and unlock full visibility into your industrial operations—whether in power generation, oil & gas, or heavy manufacturing.