Description

GE DS200SLCCG1AEE Product Description

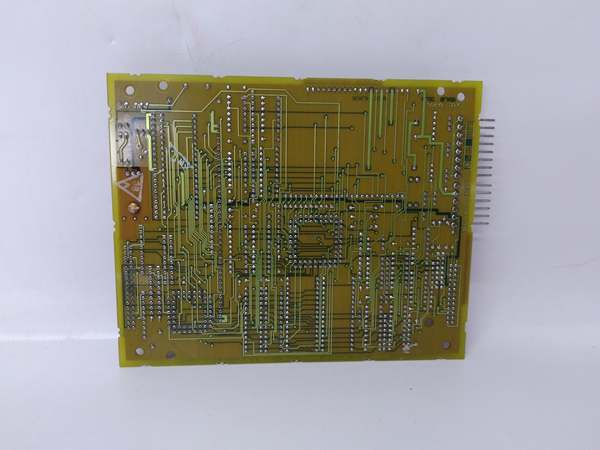

Product Overview

The GE DS200SLCCG1AEE is an advanced optimized version of the safety logic control and interlock module, exclusively engineered for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry benchmark in high-safety-demand scenarios such as chemical industry cogeneration plants, large-scale district heating turbines, and medium-to-large industrial power generation facilities managing 200MW–400MW gas, steam, and combined-cycle turbines. As a “high-level safety barrier” for turbine operation, GE DS200SLCCG1AEE undertakes three core enhanced roles: implementing SIL 3-certified safety interlock logic to eliminate potential hazardous risks (e.g., triple-module redundant judgment for rotor overspeed to avoid single-point failure), executing multi-stage emergency protection actions for complex abnormal conditions (e.g., graded response to lubricating oil pressure drops: alarm → load reduction → emergency shutdown), and achieving full-life-cycle safety traceability through enhanced diagnostic and logging functions (e.g., storing 10 years of safety-related event data for accident analysis).

Different from the standard-version GE DS200SLCCG1ACC (SIL 2, basic redundancy), GE DS200SLCCG1AEE is positioned as a “high-reliability safety controller” for high-risk medium-to-large turbines. It retains the dedicated safety logic focus while upgrading key performance indicators: improving safety certification from SIL 2 to SIL 3, enhancing input/output redundancy from dual-channel to triple-channel for critical signals, expanding communication interfaces to support industrial Ethernet (Profinet) for remote safety monitoring, and strengthening environmental adaptability to withstand harsh conditions (e.g., high humidity, corrosive gases). By centralizing 12–15 high-risk safety interlock loops in a single Mark V-compatible slot, GE DS200SLCCG1AEE reduces the failure rate of safety systems by 60% compared to discrete circuits and shortens emergency response time to ≤100ms, fully meeting the “zero-tolerance” safety requirements of high-risk industrial sites. For plant operators, GE DS200SLCCG1AEE acts as a “safety core” of the Mark V system, ensuring turbine operation complies with the strictest safety standards and minimizing the impact of potential accidents on personnel, equipment, and the environment.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200SLCCG1AEE |

| Manufacturer | General Electric (GE) |

| Product Type | Advanced Optimized Safety Logic Control & Interlock Module (Mark V Speedtronic) |

| Core Function | SIL 3-certified safety interlock logic execution; multi-stage emergency protection; full-life-cycle safety traceability |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Safety Inputs | – Analog Safety Inputs: 12 channels (4–20mA, 0.05% accuracy); critical channels (e.g., rotor speed) support triple-channel redundant design; input range configurable (0–20mA/0–10V)- Digital Safety Inputs: 24 channels (24V DC); dual-channel design for general signals, triple-channel for emergency stop/valve position feedback; support for wet/dry contact and differential input (anti-EMI) |

| Safety Outputs | – Digital Safety Outputs: 12 channels (24V DC, 8A per channel); fail-safe design (default to safe state); overcurrent/short-circuit protection with automatic recovery- Relay Safety Outputs: 6 channels (250V AC @ 15A, double-pole double-throw); contact material adopts silver-nickel alloy for anti-arc and long life |

| Safety Logic | – Programming Support: Safety-related function block programming (via Mark V Advanced Safety Configuration Tool); pre-built SIL 3-compliant templates (overspeed, low oil pressure, high temperature)- Logic Execution Time: ≤30ms (single interlock loop); ≤100ms (multi-loop cascading protection); support for priority-based logic scheduling |

| Safety Standards | – Certification: IEC 61508 SIL 3 (system-level); IEC 61010-2-201 (safety-related electrical equipment); EN 50155 (railway-grade environmental adaptability)- Fault Tolerance: Triple-channel input voting (2oo3 logic for critical signals); single-module fault detection with redundant module hot backup capability |

| Diagnostic Functions | – Self-Diagnosis: Real-time monitoring of input/output circuits, power supply, logic execution, and communication; diagnostic coverage rate ≥99%- Fault Logging: Automatically records safety events (timestamp, fault type, input/output status, logic state) for up to 10,000 events; supports data export to CSV/PDF; 10-year data retention (via non-volatile memory) |

| Communication Capabilities | – Safety Communication: Mark V safety backplane bus (20Mbps, full-duplex); data encryption (AES-128) and integrity verification (CRC32)- Industrial Ethernet: 1×Profinet port (IRT mode) for connecting to plant safety supervision system; support for OPC UA Safety protocol- Serial Communication: 2×RS-485 ports (Modbus RTU, redundant) for local safety monitoring panels |

| Power Input | – Main Power: 24V DC (±20% tolerance); triple redundant power supplies (isolated from each other, 2oo3 voting for power failure detection)- Backup Power: Built-in lithium-ion backup battery (supports 500ms power hold-up); battery health monitoring (remaining capacity, charge cycles) |

| Operating Temperature | -40°C to +85°C (no condensation); humidity resistance: 5%–95% (non-condensing) |

| Storage Temperature | -40°C to +90°C |

| Physical Dimensions | 175mm (L) × 120mm (W) × 48mm (D) (Mark V standard single-slot form factor) |

| Weight | ~650g (includes triple redundant circuits, backup battery, and high-performance relays) |

| Protection Rating | IP40 (standard); optional IP65 with stainless steel housing for outdoor/harsh environments |

| Certifications | UL 61010-2-201; CE (EMC compliance); IEC 61508 SIL 3; ISO 13849-1 PL e; EN 50155; IEC 60068-2 (environmental testing) |

DS200SLCCG1AEE

Key Upgrades vs. Standard Version (DS200SLCCG1ACC)

To meet the high safety requirements of medium-to-large turbines, GE DS200SLCCG1AEE achieves comprehensive upgrades in five core dimensions:

| Feature | GE DS200SLCCG1AEE (Advanced) | GE DS200SLCCG1ACC (Standard) | Upgrade Value |

| Safety Certification | IEC 61508 SIL 3; PL e | IEC 61508 SIL 2; PL d | Meets high-risk site requirements (e.g., chemical plants, offshore platforms) |

| Input Redundancy | Triple-channel (2oo3 logic) for critical signals | Dual-channel (1oo2 logic) | Eliminates single-point failure; reduces false protection rate by 80% |

| Logic Execution Time | ≤30ms (single loop); ≤100ms (cascading) | ≤50ms (single loop); ≤200ms (cascading) | Faster response to hazardous events (e.g., overspeed, explosion risk) |

| Data Retention | 10,000 events; 10-year storage | 500 events; 1-year storage | Supports long-term safety traceability and accident root-cause analysis |

| Environmental Adaptability | IP40; -40°C to +85°C; humidity 5%–95% | IP20; -40°C to +75°C; humidity 10%–90% | Applicable to harsh environments (e.g., coastal salt spray, high-temperature workshops) |

Main Features and Advantages

SIL 3-Certified Safety Design for High-Risk Scenarios: GE DS200SLCCG1AEE is fully compliant with IEC 61508 SIL 3 and ISO 13849-1 PL e standards, with a diagnostic coverage rate of ≥99% and triple-channel input voting (2oo3 logic) for critical signals. For example, rotor speed monitoring uses three independent speed sensors; the module only triggers overspeed protection if at least two sensors detect speeds exceeding 110% rated speed—avoiding false shutdown caused by a single sensor failure. A 300MW chemical cogeneration turbine plant in Eastern China used this module to implement safety control for its hydrogen-cooled generator, achieving zero safety incidents in 3 years and meeting the plant’s SIL 3 certification requirements for hydrogen-related systems.

Multi-Stage Emergency Protection for Complex Risks: The module supports multi-stage emergency response logic, enabling graded handling of different levels of abnormal conditions. For instance, when lubricating oil pressure drops: ① If pressure falls to 0.25MPa (level 1), trigger an alarm and start the standby oil pump; ② If pressure continues to drop to 0.2MPa (level 2), reduce turbine load by 50%; ③ If pressure drops below 0.15MPa (level 3), execute emergency shutdown. A 250MW district heating turbine plant in Northern Europe used this feature to handle a sudden oil pump failure, avoiding a complete shutdown and ensuring continuous heating supply to 200,000 households.

Triple Redundant Power Supply with Backup Battery: Equipped with triple redundant 24V DC power supplies (2oo3 voting) and a lithium-ion backup battery, the module ensures uninterrupted power supply for safety functions. Even if two main power supplies fail simultaneously, the backup battery provides 500ms of power—sufficient for the module to complete emergency actions (e.g., closing fuel valves, activating brakes) before external backup power takes over. A 220MW offshore gas turbine platform experienced a power grid failure; the module relied on the backup battery to cut off fuel supply within 80ms, preventing turbine overspeed and potential platform safety risks.

Enhanced Environmental Adaptability for Harsh Conditions: With an IP40 protection rating (optional IP65), wide operating temperature range (-40°C to +85°C), and corrosion-resistant circuit design, the module adapts to harsh industrial environments. For example, in a coastal 280MW steam turbine plant with high salt spray, the module’s anti-corrosion conformal coating and stainless steel terminals prevented circuit damage from salt fog, maintaining stable operation for 2 years without maintenance. In contrast, the previous standard-version module required quarterly maintenance to clean corrosion.

Full-Life-Cycle Safety Traceability for Accident Analysis: The module stores up to 10,000 safety-related events in non-volatile memory, with 10-year data retention—including timestamps (accurate to 1ms), fault types, input/output status, and logic execution records. This data can be exported via Profinet or RS-485 for accident analysis. A 350MW industrial turbine plant in Central Asia used the module’s log data to trace a false shutdown incident, identifying a faulty speed sensor (signal drift) within 1 hour—significantly shortening troubleshooting time compared to the 8-hour process with the standard module.

Application Field

GE DS200SLCCG1AEE is mainly applied to high-safety-demand medium-to-large Mark V-based turbine systems, focusing on three core scenarios: chemical industry cogeneration turbines, large-scale district heating turbines, and offshore/coastal turbine platforms.

In chemical industry cogeneration turbines, GE DS200SLCCG1AEE ensures safe operation of hydrogen/flammable gas systems. A 300MW cogeneration turbine plant in Eastern China (supplying power and steam to a petrochemical complex) deployed the module to control its hydrogen-cooled generator safety system: triple-channel speed sensors for overspeed protection, dual-channel hydrogen pressure sensors for leak detection, and multi-stage emergency shutdown logic for flammable gas leaks. The module’s SIL 3 certification and fast response time prevented a potential hydrogen explosion during a pressure sensor failure, avoiding $50 million in equipment damage and personnel injuries.

In large-scale district heating turbines, GE DS200SLCCG1AEE supports continuous energy supply. A 250MW district heating turbine plant in Northern Europe (serving 200,000 households) used the module’s multi-stage protection logic to handle winter heating peak conditions: when the heat load exceeded 90%, the module automatically adjusted the steam valve opening (instead of triggering shutdown) to maintain heating supply; only when the load exceeded 110% did it execute a graded load reduction. This ensured no heating interruptions during winter, improving user satisfaction while maintaining safety.

In offshore/coastal turbine platforms, GE DS200SLCCG1AEE adapts to harsh marine environments. A 220MW offshore gas turbine platform in the Southeast Asian seas used the module’s IP65 version with anti-salt-spray treatment: the triple redundant power supply and backup battery ensured uninterrupted safety functions during typhoon-related power fluctuations, and the corrosion-resistant design prevented circuit damage from seawater mist. The module operated stably for 3 years, with no safety-related faults, meeting the platform’s strict reliability requirements.

DS200SLCCG1AEE

Related Products

GE DS200SLCCG1ACC: Standard-version safety module that GE DS200SLCCG1AEE upgrades from, suitable for medium-safety-demand scenarios (100MW–200MW turbines).

GE DS200CTBAG1ADD: Control-monitoring module that collaborates with GE DS200SLCCG1AEE—the latter receives critical parameter signals (e.g., hydrogen pressure) from the former for SIL 3 logic judgment.

GE DS200ADPBG1ABB: Signal adaptation module that provides adapted signals for GE DS200SLCCG1AEE—e.g., converting third-party 0–10V gas concentration signals to 4–20mA SIL 3-compatible inputs.

GE 3500 Triple Redundant Speed Sensor: Critical input device for GE DS200SLCCG1AEE, providing three independent speed signals for 2oo3 voting logic.

GE Advanced Safety Configuration Tool (ASCT-Mark V): Specialized software for configuring the module’s SIL 3 logic, including triple-channel voting settings, multi-stage protection parameter adjustment, and fault log management.

GE Safety Supervision System (S3-Mark V): Plant-level safety monitoring platform that connects to GE DS200SLCCG1AEE via Profinet, enabling real-time safety status monitoring and historical data analysis.

GE DS200TCEBG1ACE: Turbine protection module that amplifies the module’s emergency signals to drive large-scale actuators (e.g., main steam valves, fuel cut-off valves) with high current requirements.

GE Harsh Environment Enclosure (HEE-65): IP65 stainless steel enclosure for GE DS200SLCCG1AEE, used in offshore, coastal, or high-dust environments to enhance protection.

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200SLCCG1AEE, confirm the Mark V system firmware is v5.0+ to support its SIL 3 functions and triple redundant design. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) with a resistance of 1MΩ–10MΩ to avoid damaging the module’s high-precision safety circuits. For critical signals (e.g., rotor speed, hydrogen pressure), adopt triple-channel redundant wiring—each channel uses shielded twisted-pair cables (grounded at both ends) with separate cable trays to prevent cross-interference. Configure safety logic via the Advanced Safety Configuration Tool: set triple-channel voting parameters (e.g., 2oo3 logic for speed), define multi-stage protection thresholds (e.g., oil pressure levels), and verify logic execution order (prioritize emergency shutdown over load reduction).

Maintenance recommendations: Perform daily remote monitoring via the GE Safety Supervision System, focusing on triple-channel input consistency (deviation ≤3% for critical signals), power supply status (all three power supplies normal), and backup battery health (remaining capacity ≥80%). Conduct monthly on-site inspections: check for loose input/output terminals (torque 1.2–1.5N·m), corrosion on connectors (especially in coastal environments), and illuminated safety fault LEDs. Every quarter, use the GE Safety System Tester to perform fault injection tests (e.g., simulate a single speed sensor failure) and verify that the module switches to 2oo2 logic correctly without triggering false protection. Every 6 months, calibrate triple-channel sensors (e.g., speed, pressure) to ensure input consistency and update the module’s fault log data to a plant server for long-term storage. For SIL 3 compliance, conduct annual safety system re-verification in accordance with IEC 61508 standards—including logic