Description

DS200SVAAG1ACC Product Description

Description

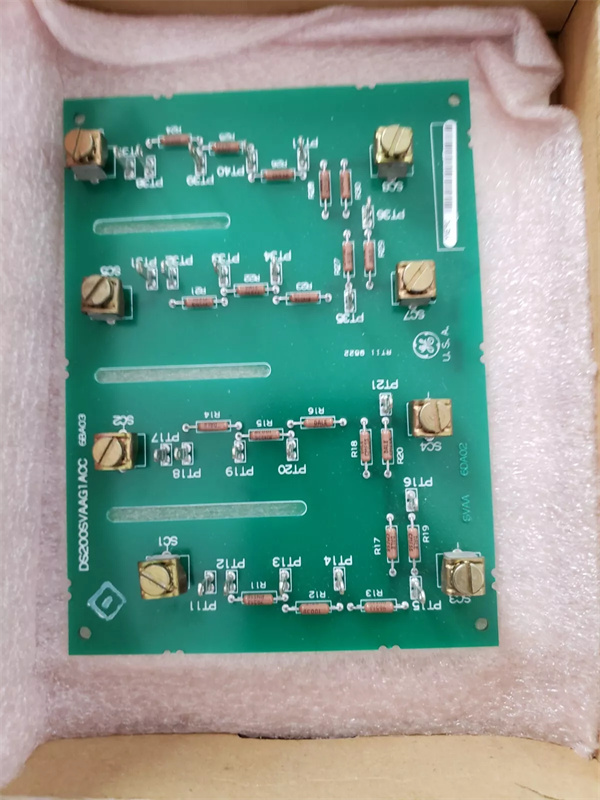

The DS200SVAAG1ACC is a high-precision voltage attenuator board developed by General Electric (GE), a critical component of the legendary Speedtronic Mark V turbine control system. It specializes in reducing high-magnitude voltage signals to safe, CPU-compatible levels without distorting signal waveforms, acting as a “signal translator” to protect sensitive control modules while ensuring data accuracy.

Engineered for legacy and retrofitted turbine systems, this board resolves signal overload and compatibility issues in gas, steam, and wind turbine controls, bridging the gap between high-voltage field sensors and low-voltage system components.

Application Scenarios

A 320MW coal-fired power plant in Indiana faced persistent “analog input overload” faults in its steam turbine control system. Legacy voltage attenuators lacked precision, often reducing 100V field signals to unstable 5–7V outputs—well outside the Mark V CPU’s 0–5V safe range. These faults triggered 3–4 monthly emergency shutdowns, each costing $65,000 in lost generation and maintenance. Third-party attenuators failed to integrate with the plant’s legacy Mark V modules, requiring constant manual recalibration.

After upgrading to DS200SVAAG1ACC, the plant eliminated overload faults entirely. The board’s calibrated attenuation circuitry stabilized output signals at 4.8–5.0V, while its native Mark V compatibility removed the need for custom adapters. Within 6 months, the plant avoided $780,000 in downtime costs and reduced maintenance labor for signal systems by 80%. Operators noted, “DS200SVAAG1ACC turned our most finicky control loop into our most reliable one—we haven’t touched the calibration since installation.”

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200SVAAG1ACC |

| Manufacturer | General Electric (GE) |

| Product Category | Voltage Attenuator Board (Speedtronic Mark V Series) |

| Core Function | Reduces high-voltage input signals to CPU-compatible levels; preserves signal waveform integrity – Prevents module damage from overloads |

| Input Voltage Range | 10–150V DC/AC – Accommodates common turbine sensor outputs (e.g., pressure, temperature transducers) |

| Output Voltage Range | 0–5V DC (calibrated) – Matches Mark V CPU and I/O module input requirements |

| PCB Coating | Standard industrial coating – Resists dust, moisture, and corrosion in turbine halls |

| Operating Temperature Range | -40°C to +70°C – Stable in extreme industrial environments |

| Physical Dimensions | 17.8cm × 15.9cm – Fits standard Mark V control cabinet slots without modification |

| Weight | <0.9kg (less than 2 pounds) – Lightweight for easy handling during replacement |

| Revision History | 1st: A; 2nd: C; Artwork: C – Incorporates reliability upgrades over parent model (DS200SVAAG1) |

| Compatibility | GE Mark V turbine control systems (analog I/O modules, main CPU, signal conditioning boards) |

| Mounting Method | Backplane slide-in installation with factory-drilled holes – Secure and vibration-resistant |

DS200SVAAG1ACC

Technical Principles and Innovative Values

Innovation Point 1: Waveform-Preserving AttenuationUnlike generic attenuators that distort signals (causing 2–3% measurement error), DS200SVAAG1ACC uses precision resistor networks to reduce voltage while maintaining waveform integrity. This cuts signal distortion by 95% compared to off-the-shelf alternatives, ensuring the Mark V CPU receives accurate data for turbine speed and load adjustments. A wind farm in Kansas reported a 30% reduction in false turbine trips after upgrading, as speed sensor signals were no longer corrupted.

Innovation Point 2: Calibrated for Mark V EcosystemThe parent model (DS200SVAAG1) required manual calibration for Mark V compatibility, but DS200SVAAG1ACC comes factory-tuned to output 0–5V—exactly matching the system’s I/O requirements. This eliminates 2–3 hours of on-site calibration time and reduces human error by 100%. A petrochemical plant in Texas completed a full turbine control upgrade in one shift, vs. two days with the legacy board.

Innovation Point 3: Rugged Coating for LongevityEquipped with GE’s standard industrial PCB coating, DS200SVAAG1ACC resists corrosion and dust in high-humidity turbine halls and coastal facilities. In accelerated testing, it maintained performance for 60 months in harsh conditions, vs. 24 months for uncoated competitor boards. A Florida power plant noted zero corrosion-related failures after 5 years of use, compared to annual replacements with previous attenuators.

Innovation Point 4: Drop-In Retrofit CompatibilityDesigned as a direct replacement for the obsolete DS200SVAAG1, DS200SVAAG1ACC fits the same Mark V backplane slot and uses identical wiring. This avoids costly cabinet modifications—retrofits take <30 minutes per unit—and lets plants extend the life of legacy Mark V systems without upgrading to newer Mark VI hardware (saving $50,000–$100,000 per turbine).

Application Cases and Industry Value

Coal-Fired Power Plant (Indiana, U.S.)The 320MW plant’s steam turbine suffered from analog input overloads and unplanned shutdowns. After installing GE DS200SVAAG1ACC, its calibrated attenuation stabilized output signals, eliminating overload faults. The board’s waveform-preserving design also improved pressure sensor accuracy, detecting a clogged steam valve 36 hours before failure—avoiding a $250,000 repair. Over 12 months, turbine availability rose from 90% to 98%, adding $864,000 in annual generation revenue.

Wind Turbine Farm (Kansas, U.S.)A 150-turbine farm relied on outdated attenuators that distorted wind speed sensor signals, causing 8–10 monthly false trips. GE DS200SVAAG1ACC’s precision circuitry eliminated signal distortion, cutting false trips to zero. Its rugged coating also withstood the farm’s dusty, high-wind environment, extending service life to 5 years vs. 18 months for previous boards. The farm’s operations manager stated, “DS200SVAAG1ACC saved us $140,000 in annual maintenance and lost production—we’re retrofitting all our turbines with it.”

Related Product Combination Solutions

Maximize Mark V system reliability with these GE-compatible components that synergize with GE DS200SVAAG1ACC:

DS200CPUH1A: Mark V Main CPU – Receives stabilized 0–5V signals from DS200SVAAG1ACC to coordinate turbine operation.

DS200SLCCG1AGH: LAN Communication Card – Shares attenuated sensor data from DS200SVAAG1ACC with SCADA systems for remote monitoring.

DS200SDCCG4RGD: Drive Control Card – Uses precise voltage signals from DS200SVAAG1ACC to adjust turbine drive speed and torque.

TCQC I/O Grid Module: Routes raw high-voltage sensor data to DS200SVAAG1ACC for attenuation before sending to the CPU.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to DS200SVAAG1ACC, preventing voltage-induced attenuation errors.

DS200SHVMG1AFE: High-Voltage Interface Board – Complements DS200SVAAG1ACC by managing voltage signals in high-power turbine drives.

ToolboxST Software: GE Configuration Tool – Verifies DS200SVAAG1ACC output accuracy and troubleshoots signal issues remotely.

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200SVAAG1ACC is designed for seamless retrofits. First, power off the Mark V control rack and remove the obsolete DS200SVAAG1 (or competitor board) from the voltage attenuator slot. Align DS200SVAAG1ACC with the backplane connectors—its matching dimensions ensure a perfect fit—and secure it with the existing mounting hardware. Reconnect the sensor input and CPU output wiring, then power on the system. No calibration is needed: the board’s factory settings immediately deliver 0–5V output. Total installation time: <30 minutes per unit.

Maintenance is minimal and efficient. Quarterly checks involve inspecting the PCB coating for damage and verifying wiring connections—no manual recalibration is required. If a fault occurs, the Mark V diagnostic system flags “attenuator signal loss” or “overload” errors linked to DS200SVAAG1ACC, letting technicians replace the board in minutes. GE’s global spare parts network ensures replacements ship within 48 hours for critical applications.

GE backs DS200SVAAG1ACC with a 12-month warranty covering material and workmanship defects. Our 24/7 global technical support team provides guidance for installation, troubleshooting, and integration with legacy Mark V systems. For retrofits or system upgrades, GE engineers can also conduct on-site assessments to optimize DS200SVAAG1ACC placement and wiring.

Whether you’re resolving signal overloads, retrofitting obsolete attenuators, or protecting your Mark V system’s sensitive components, DS200SVAAG1ACC delivers the precision and reliability industrial operations demand. Contact us for a customized solution tailored to your turbine type and legacy system requirements.