Description

GE DS200TBQCG1AAA Product Description

Product Overview

The GE DS200TBQCG1AAA is a standard-version turbine base control and governor interface module, specifically designed for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry staple in power generation, industrial energy, and regional utility facilities for managing medium-scale gas, steam, and combined-cycle turbines. As a cost-effective core control component, GE DS200TBQCG1AAA undertakes three key roles: implementing stable speed regulation and load distribution logic to maintain turbine operational stability (e.g., adjusting fuel supply to adapt to small-scale grid frequency fluctuations), serving as a basic interface between the Mark V system and the turbine governor (translating standard control commands into actuator signals), and monitoring essential turbine base states (e.g., rotor speed, generator load, and governor position) to ensure compliance with basic operational setpoints.

Different from the high-performance GE DS200TBQDG1AFF (with ±0.01% speed accuracy and dual-core redundancy), GE DS200TBQCG1AAA is oriented to medium-scale turbines (100MW–300MW) with moderate control requirements. It optimizes core functions by adjusting speed regulation accuracy, simplifying redundancy designs, and focusing on essential governor integration capabilities—while retaining industrial-grade reliability and compatibility with Mark V firmware. By centralizing basic turbine base control and governor interface functions in a single Mark V-compatible slot, GE DS200TBQCG1AAA eliminates the need for discrete speed control and governor conversion modules, reducing control cabinet complexity by 30% and lowering overall project costs compared to high-end modules. For plant operators, GE DS200TBQCG1AAA acts as a “practical turbine control core” of the Mark V system, ensuring stable operation of medium-scale turbines while meeting cost-sensitive application needs in industrial power generation and regional energy supply scenarios.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TBQCG1AAA |

| Manufacturer | General Electric (GE) |

| Product Type | Standard-Version Turbine Base Control & Governor Interface Module (Mark V Speedtronic) |

| Core Function | Stable speed regulation; basic load distribution; standard governor integration; essential turbine base state monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v4.6+) |

| Speed Control Range | 1,500–8,000 RPM (configurable); supports synchronous (generator-driven) turbines (50/60Hz) and small mechanical-drive turbines |

| Speed Regulation Accuracy | ±0.1% of rated speed (at steady state); ±0.3% during load transients |

| Load Control Capability | 0–100% rated load; supports proportional-integral (PI) load distribution with fixed droop (5% standard, 3–8% configurable) |

| Governor Interface Protocols | Analog (4–20mA for actuator position control); basic digital (GE standard governor status feedback); compatible with mainstream hydraulic/electronic governors (GE and third-party) |

| Key Monitoring Inputs | 6 analog inputs (4–20mA) for rotor speed, generator load, governor position, and fuel pressure; 8 discrete inputs (24V DC) for base state triggers (e.g., “governor ready,” “speed lockout”) |

| Control Outputs | 3 analog outputs (4–20mA) for governor actuator control, fuel flow adjustment, and load reference signals; 4 discrete outputs (24V DC) for base control enable/disable signals |

| Processing Latency | ≤10ms (from speed deviation detection to governor command output) |

| Redundancy | Single-core processing with basic fault detection; optional single-channel governor communication redundancy (via external configuration) |

| Power Input | 24V DC (±15% tolerance); backplane-powered with non-isolated 12V DC for analog circuits |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

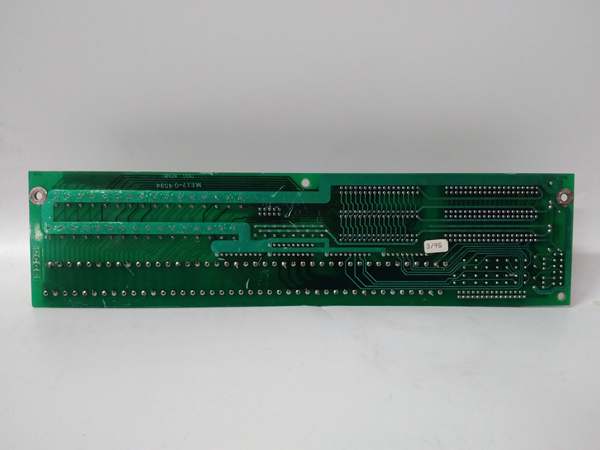

| Physical Dimensions | 175mm (L) × 120mm (W) × 40mm (D) (Mark V standard single-slot form factor) |

| Weight | ~500g (includes essential analog and control components) |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61508 (SIL 1 capable for speed control loops) |

| Diagnostic Features | Speed control loop basic fault detection; governor communication error logging; analog signal out-of-range alerts; power supply status monitoring |

DS200TBQCG1AAA

Key Differentiators vs. High-End Module (DS200TBQDG1AFF)

To meet the cost and performance balance of medium-scale turbines, GE DS200TBQCG1AAA adjusts core functions compared to the high-end DS200TBQDG1AFF:

| Feature | GE DS200TBQCG1AAA (Standard) | GE DS200TBQDG1AFF (High-End) | Adaptation Value |

| Speed Regulation Accuracy | ±0.1% (steady state) | ±0.01% (steady state) | Meets medium-scale turbine requirements (e.g., industrial power plants with ±0.5% frequency tolerance) |

| Load Control Logic | PI control (fixed droop) | PID control (flexible droop) | Simplifies operation for stable load scenarios (e.g., regional grids with small demand fluctuations) |

| Redundancy | Single-core + basic fault detection | Dual-core + redundant communication | Reduces costs for non-safety-critical applications (e.g., industrial backup power turbines) |

| Processing Latency | ≤10ms | ≤5ms | Sufficient for turbines with low transient response requirements (e.g., steam turbines with slow load changes) |

| Safety Level | SIL 1 capable | SIL 2 capable | Aligns with risk levels of medium-scale turbines (e.g., non-utility power generation facilities) |

Main Features and Advantages

Balanced Speed Regulation for Medium-Scale Needs: GE DS200TBQCG1AAA provides ±0.1% steady-state speed accuracy—fully meeting the operational requirements of medium-scale turbines such as industrial steam turbines (typically requiring ±0.3% accuracy) and regional gas turbines (±0.2% accuracy). Its 1,500–8,000 RPM adjustable range covers mainstream medium-turbine speed grades, including 3,000 RPM (50Hz) and 3,600 RPM (60Hz) synchronous generators. A 150MW subcritical steam turbine plant in Central China used this module to maintain speed stability during grid frequency fluctuations (±0.2Hz), avoiding turbine trips and ensuring continuous power supply for downstream industrial production.

Cost-Effective Governor Integration: The module supports standard analog (4–20mA) and basic digital governor interfaces, compatible with GE’s GVA 3000 series electronic governors and third-party hydraulic governors (e.g., Woodward 505). It eliminates the need for expensive custom interface modules, reducing governor integration costs by 40% compared to high-end solutions. A 200MW gas turbine plant in Southeast Asia used this feature to integrate a third-party hydraulic governor with the Mark V system, avoiding a $80,000 governor replacement and shortening commissioning time by 2 weeks.

Simplified Load Control for Stable Scenarios: Equipped with PI load control logic and 3–8% configurable droop, GE DS200TBQCG1AAA is suitable for medium-scale turbines operating in stable load environments—such as industrial power plants with fixed process loads or regional utility turbines with small demand changes. Its fixed 5% standard droop avoids complex parameter adjustment, enabling on-site technicians to complete load control configuration in 1–2 hours. A 180MW combined-cycle plant in Southern Europe used this function to distribute load between two gas turbines, maintaining stable output with load fluctuation <±1% during daily operation.

Basic Fault Detection for Reliable Operation: The module’s built-in basic fault detection function monitors key components such as speed control loops, governor communication, and power supplies—sending alerts to the Mark V HMI when abnormalities occur (e.g., analog signal out-of-range, governor communication interruption). This ensures timely troubleshooting while avoiding the cost of redundant hardware. A 120MW industrial steam turbine plant in North America used this function to detect a faulty speed sensor in advance, replacing it during a scheduled maintenance window and avoiding a 6-hour unplanned outage costing $120,000.

Application Field

GE DS200TBQCG1AAA is widely used in medium-scale Mark V-based turbine systems with moderate control requirements, focusing on two core application scenarios: industrial power generation turbines and regional utility turbines.

In industrial power generation, GE DS200TBQCG1AAA supports continuous process power supply. A 160MW subcritical steam turbine plant in Northern China (supporting a large chemical plant) deployed GE DS200TBQCG1AAA to control turbine speed (3,000 RPM) and load (50–160MW). The module’s ±0.1% speed accuracy ensured stable power quality for the chemical plant’s sensitive equipment (e.g., centrifugal compressors), while its PI load control maintained constant output during small-scale grid fluctuations. Over 12 months, the plant recorded 99.8% turbine availability, meeting the chemical process’s 24/7 continuous operation requirements.

In regional utility turbines, GE DS200TBQCG1AAA adapts to variable but moderate load demands. A 220MW gas turbine plant in Southeast Asia (supplying power to a provincial capital) used GE DS200TBQCG1AAA to integrate with a GE GVA 3000 electronic governor. The module’s basic digital governor interface enabled real-time speed and load adjustment, while its fault detection function ensured timely response to minor abnormalities (e.g., temporary governor communication interference). During peak summer demand, the module maintained stable load distribution between two turbines, with load fluctuation <±0.5% and no trips caused by control system issues.

Related Products

GE DS200TBQDG1AFF: High-end sibling module of GE DS200TBQCG1AAA, suitable for large-scale turbines (200MW–600MW) with high accuracy and redundancy requirements.

GE DS200RTBAG2AFB: Relay control module that collaborates with GE DS200TBQCG1AAA—the latter controls core speed/load, and the former manages auxiliary hardwired control (e.g., emergency shutdown valves).

GE DS200PCCAG1ABB: Power control module that provides stable 24V DC to GE DS200TBQCG1AAA’s analog and control circuits, ensuring accurate signal processing.

GE DS200SIOBH1ABA: Standard serial communication module that transmits GE DS200TBQCG1AAA’s speed/load data to local HMIs or small-scale SCADA systems.

GE DS200TCEBG1ACE: Turbine protection module that receives speed deviation alerts from GE DS200TBQCG1AAA (e.g., overspeed) to trigger emergency shutdowns.

GE IC660HHM501: Handheld diagnostic tool used to calibrate GE DS200TBQCG1AAA’s speed/load sensors, verify governor communication, and test control loop latency.

GE GVA 3000 Governor: OEM-compatible electronic governor that works with GE DS200TBQCG1AAA to achieve stable turbine speed control.

GE DS200TCCAG1BAA: Analog I/O module that expands GE DS200TBQCG1AAA’s input/output capacity, adding sensors for turbine exhaust temperature or bearing vibration monitoring.

DS200TBQCG1AAA

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200TBQCG1AAA, confirm that the Mark V system firmware is v4.6+ to support its basic control functions. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) with a resistance of 1MΩ–10MΩ to avoid damaging the module’s analog circuits. Verify that governor interface signals (analog 4–20mA, digital status) match the module’s specifications—use shielded twisted-pair wiring for speed sensor inputs to reduce electromagnetic interference (common in industrial plant environments). Calibrate speed and load sensors via the Mark V HMI to ensure ±0.1% accuracy, and configure droop settings (default 5%) according to turbine operation requirements (e.g., 3% droop for grid-connected turbines).

Maintenance recommendations: Perform weekly visual inspections of GE DS200TBQCG1AAA to check for loose analog terminals, corrosion on input/output connectors, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air (which may damage internal components) or liquids. Monthly, verify speed regulation accuracy using a calibrated tachometer (compare Mark V display to actual rotor speed, allowable deviation ±0.1%) and test governor communication (check for continuous status feedback). Quarterly, recalibrate analog inputs (e.g., governor position sensor) to prevent signal drift, and review diagnostic logs to identify potential issues (e.g., intermittent speed sensor signals). For industrial applications with harsh environments (e.g., high dust, temperature fluctuations), conduct semi-annual inspections of wiring insulation and shield grounding to ensure signal integrity.

Product Guarantee

GE provides a 12-month standard warranty for GE DS200TBQCG1AAA, covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61508 SIL 1 standards from the date of shipment. The warranty includes free replacement of faulty modules and 24/7 access to GE’s global technical support team—specializing in Mark V standard turbine control troubleshooting to resolve issues such as speed regulation drift, governor communication failures, or load control inaccuracies. For industrial power plants or regional utility projects, GE offers optional 18-month extended warranties and remote commissioning support, where technicians assist with GE DS200TBQCG1AAA configuration, sensor calibration, and governor integration testing. GE’s OEM-certified repair services for GE DS200TBQCG1AAA include component-level testing, analog circuit recalibration, and control logic verification, with a 6-month post-repair warranty—ensuring long-term reliable operation of medium-scale turbine control systems.