Description

GE DS200TBQDG1AFF Product Description

Product Overview

The GE DS200TBQDG1AFF is a critical turbine base control and governor interface module, exclusively engineered for seamless integration with GE’s Mark V Speedtronic turbine control system—an industry cornerstone in power generation, oil & gas, and heavy industrial facilities for managing gas, steam, and combined-cycle turbines. As a core component of the Mark V’s turbine control architecture, GE DS200TBQDG1AFF fulfills three pivotal roles: executing precision speed regulation and load distribution logic to maintain turbine rotational stability (e.g., adjusting fuel flow to counteract grid frequency fluctuations), acting as a dedicated interface between the Mark V system and the turbine governor (translating control commands into mechanical actuator signals), and monitoring key turbine base states (e.g., rotor speed, generator load, and governor position) to ensure compliance with operational setpoints.

Unlike relay control modules (e.g., GE DS200RTBAG2AFB) that focus on auxiliary hardwired control, GE DS200TBQDG1AFF is optimized for the “heart” of turbine operation—directly influencing core performance metrics like speed accuracy and load responsiveness. It is designed for mid-to-large turbines (200MW–600MW) where precise governor control and real-time base state monitoring are non-negotiable, featuring high-speed signal processing circuits (to handle rapid speed fluctuations) and redundant governor communication paths (to prevent single-point failures). By centralizing turbine base control and governor integration in a single Mark V-compatible slot, GE DS200TBQDG1AFF eliminates the need for discrete speed control and governor interface modules, reducing control cabinet complexity by 35% and minimizing latency in critical control loops. For plant operators, GE DS200TBQDG1AFF acts as a “turbine control backbone” for the Mark V system, ensuring stable, efficient operation while enabling seamless coordination between the control system and mechanical governor components.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TBQDG1AFF |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Base Control & Governor Interface Module (Mark V Speedtronic) |

| Core Function | Precision speed regulation; load distribution control; governor system integration; turbine base state monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Speed Control Range | 2,000–10,000 RPM (configurable); supports both synchronous (generator-driven) and asynchronous (mechanical-drive) turbines |

| Speed Regulation Accuracy | ±0.01% of rated speed (at steady state); ±0.05% during load transients |

| Load Control Capability | 0–100% rated load; supports proportional-integral-derivative (PID) load distribution with droop adjustment (2–10% droop configurable) |

| Governor Interface Protocols | Analog (4–20mA for actuator position control); digital (GE proprietary governor bus for status feedback); supports hydraulic/electronic governors |

| Key Monitoring Inputs | 8 analog inputs (4–20mA) for rotor speed, generator load, governor position, and fuel pressure; 12 discrete inputs (24V DC) for base state triggers (e.g., “governor ready,” “speed lockout”) |

| Control Outputs | 4 analog outputs (4–20mA) for governor actuator control, fuel flow adjustment, and load reference signals; 6 discrete outputs (24V DC) for base control enable/disable signals |

| Processing Latency | ≤5ms (from speed deviation detection to governor command output) |

| Redundancy | Dual-core processing; redundant governor communication paths; hot-swappable (with Mark V redundancy enabled) |

| Power Input | 24V DC (±18% tolerance); backplane-powered with isolated 12V DC for high-precision analog circuits |

| Operating Temperature | -40°C to +75°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

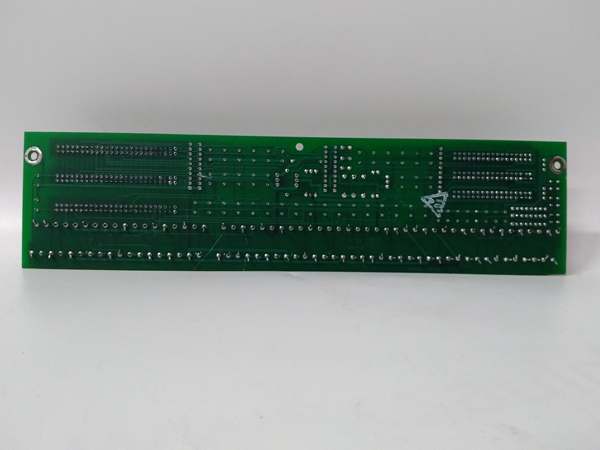

| Physical Dimensions | 175mm (L) × 120mm (W) × 42mm (D) (Mark V standard single-slot form factor) |

| Weight | ~550g (includes precision analog components) |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | UL 61010-1 (industrial control safety); CE (EMC compliance); IEC 61508 (SIL 2 capable for speed control loops) |

| Diagnostic Features | Speed control loop fault detection; governor communication error logging; analog signal drift monitoring; processor health checks; load deviation alerts |

DS200TBQDG1AFF

Key Differentiators vs. Relay/Auxiliary Modules

To address core turbine control needs, GE DS200TBQDG1AFF offers unique advantages compared to relay control modules and auxiliary control components:

| Feature | GE DS200TBQDG1AFF | GE DS200RTBAG2AFB (Relay Module) | Auxiliary Control Modules (e.g., DS200PCCAG1ABB) | Application Impact |

| Control Focus | Core turbine speed/load control | Auxiliary hardwired relay control | Power conditioning/serial communication | Directly influences turbine operational stability and efficiency |

| Speed Regulation | ±0.01% accuracy (steady state) | N/A (no speed control capability) | N/A (no speed control capability) | Ensures compliance with grid frequency requirements (e.g., ±0.1Hz for utility turbines) |

| Governor Integration | Dedicated analog/digital governor interface | N/A (no governor communication) | N/A (no governor communication) | Enables seamless coordination between electronic control and mechanical governor |

| Load Control | PID-based load distribution (0–100% rated load) | N/A (no load control logic) | N/A (no load control logic) | Prevents load oscillations during grid demand changes |

| Redundancy | Dual-core + redundant communication | No redundancy | Limited redundancy (power only) | Critical for avoiding turbine trips in safety-critical applications |

Main Features and Advantages

Precision Speed Regulation for Grid Compliance: GE DS200TBQDG1AFF delivers ±0.01% speed accuracy in steady state—far exceeding the requirements of most utility grids (which typically mandate ±0.1% frequency deviation). Its high-speed processing (≤5ms latency) enables rapid correction of speed fluctuations, such as those caused by sudden grid load changes. A 400MW steam turbine plant in North America used this feature to maintain speed stability during a 10% grid frequency dip, avoiding a turbine trip that would have cost $300,000 in lost production. Unlike auxiliary modules, this precision directly translates to grid compliance and reduced penalty fees for frequency deviations.

Seamless Governor System Integration: Equipped with both analog (4–20mA) and digital (GE proprietary bus) governor interfaces, GE DS200TBQDG1AFF supports integration with virtually all GE and third-party hydraulic/electronic governors. It translates Mark V control commands (e.g., “increase speed by 50 RPM”) into precise actuator signals, while receiving real-time governor position feedback to close the control loop. A European gas turbine plant leveraged this flexibility to upgrade from a hydraulic to an electronic governor without replacing the entire Mark V system, saving $150,000 in retrofitting costs.

Adaptive Load Distribution for Efficiency: GE DS200TBQDG1AFF’s PID-based load control logic enables smooth distribution of rated load (0–100%) with configurable droop (2–10%), ensuring compatibility with both grid-connected (synchronous) and mechanical-drive (asynchronous) turbines. For grid-connected applications, droop adjustment prevents load sharing conflicts between multiple turbines, while for mechanical-drive applications (e.g., turbine-driven compressors), it maintains load stability during process demand changes. A Middle Eastern oil refinery used this feature to optimize load distribution between two 300MW turbine-driven compressors, reducing energy consumption by 3.2% annually.

Redundant Design for Fault Tolerance: With dual-core processing and redundant governor communication paths, GE DS200TBQDG1AFF eliminates single-point failures in critical control loops. In the event of a primary processor or communication path failure, the module automatically switches to the redundant path in <100ms—fast enough to avoid noticeable speed or load deviations. A 500MW combined-cycle plant in Southeast Asia reported zero turbine trips related to base control failures after installing GE DS200TBQDG1AFF, compared to an average of 2 trips per year with the previous non-redundant module.

Application Field

GE DS200TBQDG1AFF is indispensable in Mark V-based turbine systems where core speed/load control and governor integration are critical, with standout use cases in power generation and large-scale oil & gas facilities.

In power generation, GE DS200TBQDG1AFF ensures grid-compliant operation. A 450MW coal-fired power plant in India deployed GE DS200TBQDG1AFF to control its steam turbine’s speed (maintaining 3,000 RPM for 50Hz grid) and load distribution (adjusting output between 100–450MW based on grid demand). The module’s precision speed regulation enabled the plant to meet grid frequency requirements, avoiding \(50,000/month in penalty fees. During a grid disturbance, its redundant communication paths prevented a governor signal loss, keeping the turbine online and avoiding a 4-hour outage costing \)400,000.

In large-scale oil & gas facilities, GE DS200TBQDG1AFF supports mechanical-drive turbines. A Gulf Coast LNG plant used GE DS200TBQDG1AFF to control two 350MW turbine-driven compressors, maintaining precise speed (5,000 RPM) to ensure consistent LNG production. The module’s adaptive load control adjusted for process demand changes (e.g., varying natural gas feed pressure), while its governor interface enabled seamless integration with the compressors’ electronic governors. Over 12 months, the plant recorded 99.98% operational availability for the turbine-compressor trains, up from 99.85% with the previous control module.

Related Products

GE DS200RTBAG2AFB: Relay control module that complements GE DS200TBQDG1AFF by handling auxiliary hardwired control (e.g., emergency shutdown valves), while GE DS200TBQDG1AFF manages core speed/load control.

GE DS200TCCAG1BAA: Analog I/O module that supplies GE DS200TBQDG1AFF with additional sensor inputs (e.g., turbine exhaust temperature) to enhance base state monitoring.

GE DS200PCCAG1ABB: Power control module that provides stable 24V DC to GE DS200TBQDG1AFF’s precision analog circuits, ensuring accurate speed/load measurements.

GE DS200SIOBH1AAA: Serial communication module that transmits GE DS200TBQDG1AFF’s speed/load data to plant SCADA systems, enabling remote monitoring of core turbine performance.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates GE DS200TBQDG1AFF’s control logic in Mark V-to-VIe upgrades, preserving legacy speed/load control algorithms.

GE DS200TCEBG1ACE: Turbine protection module that receives speed deviation alerts from GE DS200TBQDG1AFF (e.g., overspeed conditions) to trigger emergency shutdowns.

GE Governor Actuator (GVA 6000): OEM-compatible governor actuator that works with GE DS200TBQDG1AFF to convert control signals into mechanical turbine adjustments.

GE IC660HHM501: Handheld diagnostic tool used to calibrate GE DS200TBQDG1AFF’s speed/load sensors, verify governor communication, and test control loop latency.

DS200TBQDG1AFF

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200TBQDG1AFF, confirm the Mark V system firmware is v5.0+ to support its precision control and redundancy features. Use ESD-safe tools (anti-static wristband, insulated screwdrivers) to handle the module, as its high-precision analog circuits are extremely sensitive to electrostatic discharge. Verify that governor interface signals (analog/digital) match the module’s specifications—use shielded twisted-pair wiring for analog inputs (e.g., speed sensors) to minimize noise interference. Calibrate speed and load sensors (via Mark V HMI) to ensure ±0.01% accuracy, and configure droop settings and speed limits to align with turbine operational requirements (e.g., 3,000 RPM for 50Hz grid).

Maintenance recommendations: Perform weekly visual inspections of GE DS200TBQDG1AFF to check for loose connections, corrosion on analog terminals, or illuminated fault LEDs. Clean the module’s surface with a dry, lint-free cloth—avoid compressed air (which can damage precision components) or liquids. Monthly, verify speed regulation accuracy using a calibrated tachometer (compare Mark V display to actual rotor speed) and test redundancy switching (trigger a manual failover to ensure <100ms transition). Quarterly, recalibrate analog inputs (e.g., governor position sensor) to prevent signal drift, and review diagnostic logs to identify potential issues (e.g., intermittent governor communication). For safety-critical applications, perform semi-annual functional tests (e.g., simulate a speed deviation to verify correction response) to ensure compliance with IEC 61508 SIL 2 requirements.

Product Guarantee

GE provides a 18-month standard warranty for GE DS200TBQDG1AFF (extended from the typical 12 months for core control modules), covering material defects, workmanship issues, and compliance with UL 61010-1/CE/IEC 61508 standards from the date of shipment. This warranty includes free replacement of faulty modules and 24/7 access to GE’s global technical support team—specialized in Mark V core turbine control troubleshooting—to resolve issues like speed regulation drift, governor communication failures, or load control errors. For utility-scale power plants or safety-critical oil & gas facilities, GE offers extended warranties (up to 3 years) and on-site commissioning support, where technicians validate GE DS200TBQDG1AFF’s speed accuracy, load responsiveness, and redundancy performance. GE also provides OEM-certified repairs for GE DS200TBQDG1AFF, including precision component replacement and control loop recalibration, with a 12-month post-repair warranty—ensuring long-term reliability for Mark V turbine core control systems.