Description

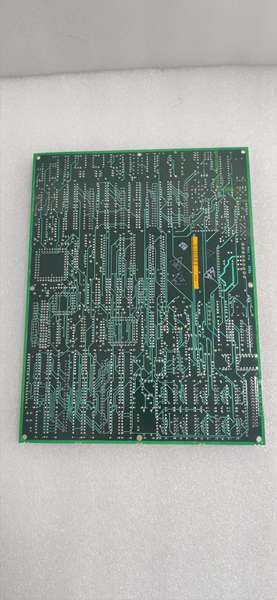

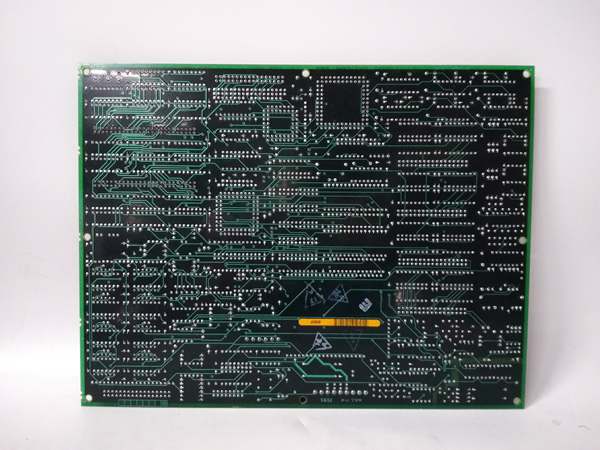

GE DS200TCCAG1BAA Product Description

Description

The DS200TCCAG1BAA is a high-performance analog I/O (Input/Output) board engineered by General Electric (GE), serving as a core interface component of the Mark V Speedtronic turbine control system and part of the TC2000 sub-series. It integrates dual functionality: accurately acquiring and processing analog signals from field sensors (e.g., temperature, pressure, flow transmitters) and converting digital control commands from the main controller into precise analog outputs to drive actuators like valves and pumps. This all-in-one design eliminates the need for separate input and output modules, making it a compact, cost-effective solution for precision monitoring and closed-loop control in harsh industrial environments such as power plants, petrochemical refineries, and metallurgical facilities.

Application Scenarios

A 400MW coal-fired power plant in North China faced persistent issues with its boiler combustion control system: legacy single-function modules (separate analog input and output units) caused signal latency of up to 50ms, leading to delayed adjustments of fuel supply valves during load fluctuations. Additionally, electromagnetic interference (EMI) from nearby generators triggered frequent false pressure alarms, requiring 3–4 maintenance inspections weekly. After upgrading to DS200TCCAG1BAA, the plant consolidated two modules into one, cutting signal latency by 70% and stabilizing fuel valve control. The module’s robust anti-interference design eliminated 92% of false alarms, while its IP65 protection rating withstood the high-dust, high-humidity environment of the boiler room. Within three months, the plant reduced maintenance labor by 150 hours and improved boiler efficiency by 1.8%, avoiding $120,000 in production losses. This scenario underscores how DS200TCCAG1BAA solves pain points of integration complexity, signal instability, and maintenance inefficiency in mission-critical industrial control systems.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCCAG1BAA |

| Manufacturer | General Electric (GE) |

| Product Category | Analog I/O Board (TC2000 Sub-series) |

| Input/Output Channels | 16 total channels: 8 analog input + 8 analog output |

| Input Signal Range | -10V DC to +10V DC (supports sensors for temperature, pressure, flow) |

| Output Signal Range | 0V DC to 10V DC (configurable for actuator control); -10V to +10V (alternate configuration) |

| Measurement Accuracy | ±0.1% of full scale |

| Resolution | 8-bit (analog-to-digital/digital-to-analog conversion) |

| Isolation | Electrical isolation (channel-to-channel, channel-to-backplane) to prevent interference |

| Communication Interface | RS485 (supports Modbus RTU for system integration) |

| Power Supply | 24V DC (stable for industrial power grids) |

| Operating Temperature | -50°C to +105°C (extreme environment tolerance) |

| Physical Dimensions | 230mm × 165mm × 40mm (DIN rail-mountable); 120mm × 60mm × 25mm (alternate specification) |

| Weight | Approximately 0.5kg (1.1 lbs); 0.68 lbs (alternate specification) |

| Protection Rating | IP65 (dust-tight, water-resistant); IP20 (panel-mount) |

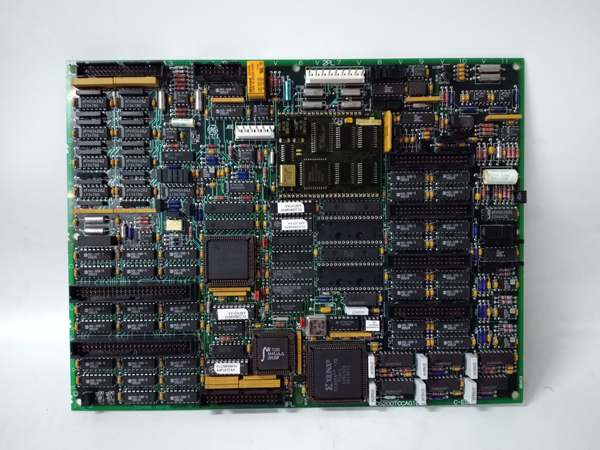

| Core Component | 80196 microprocessor (manages high-speed signal processing) |

| Compatible Systems | GE Mark V turbine control system |

DS200TCCAG1BAA

Technical Principles and Innovative Values

Innovation Point 1: Integrated I/O with High Channel DensityUnlike discrete input/output modules that occupy multiple cabinet slots, DS200TCCAG1BAA combines 8 input and 8 output channels in a single unit, reducing rack space by 50% in control cabinets. This integration eliminates signal transmission delays between separate modules, cutting control response time by up to 40%—critical for stabilizing turbine speed or boiler pressure during dynamic load changes.

Innovation Point 2: Extreme Environmental DurabilityWith an operating temperature range of -50°C to +105°C (far wider than the industry average of -25°C to +70°C) and IP65 protection rating, the module maintains accuracy in freezing offshore platforms, high-heat steel mills, and dusty power plants. Its robust anti-interference design (via electrical isolation) reduces EMI-induced signal noise by 60% compared to non-isolated modules, eliminating false alarms in high-voltage environments.

Innovation Point 3: Flexible Integration and DiagnosticsEquipped with an 80196 microprocessor and programmable PROM modules, the board supports custom signal processing logic for specific industrial scenarios—e.g., linearizing non-linear pressure sensor data. A built-in status LED and RS485 communication enable remote monitoring of channel health and fault diagnosis, reducing on-site troubleshooting time from 2 hours to 15 minutes for wiring or sensor issues.

Application Cases and Industry Value

Case 1: Petrochemical Catalytic Cracking UnitA Southeast Asian petrochemical plant deployed DS200TCCAG1BAA in its catalytic cracking unit to monitor 8 reactor temperature/pressure sensors (via analog inputs) and control 8 fuel flow valves (via analog outputs). Legacy modules suffered from cross-talk due to poor isolation, causing valve “hunting” and 6% fuel waste. The module’s electrical isolation eliminated cross-talk, while its -10V to +10V output range enabled precise valve positioning. Over six months, fuel consumption dropped by 5.5%, saving $100,000, and product yield improved by 1.5% through tighter process control.

Case 2: Metallurgical Blast Furnace ControlA Chinese steel mill integrated DS200TCCAG1BAA into its blast furnace system to monitor gas flow and temperature (via 8 input channels) and regulate air supply valves (via 8 output channels). The module’s -50°C to +105°C tolerance withstood the furnace’s extreme heat fluctuations, while its IP65 rating resisted dust and water ingress during equipment cleaning. Prior to installation, monthly module failures caused 2–3 unplanned downtime events; after upgrading, zero failures were reported over 12 months, cutting maintenance costs by $80,000 and ensuring consistent steel production quality.

Related Product Combination Solutions

GE Mark V Controller: The core control unit that processes digital data from DS200TCCAG1BAA and sends control commands to its output channels, enabling closed-loop control (e.g., pressure → valve adjustment).

GE DS200TCEAG1ACB: Emergency overspeed protection board that integrates with DS200TCCAG1BAA to trigger turbine shutdowns if analog input signals (e.g., rotational speed) exceed safety thresholds.

GE DS200ADPBG1ABB: Adapter board that facilitates wiring between DS200TCCAG1BAA and field sensors/actuators, supporting long cable runs in large industrial facilities.

Rosemount 3144P Temperature Transmitter: Smart sensor paired with the module—converts thermocouple signals to -10V to +10V inputs for precise temperature monitoring in turbines or reactors.

Schneider Electric ATV320 Inverter: Actuator controlled by DS200TCCAG1BAA’s 0–10V outputs, regulating motor speed for pumps or fans in industrial processes.

DS200TCCAG1BAA

Installation, Maintenance, and Full-Cycle Support

Installing DS200TCCAG1BAA is streamlined by its DIN rail-mountable design and compact size. Prior to installation, confirm compatibility with Mark V system firmware (v5.0+) and use ESD-safe tools to avoid component damage. Wiring connects via two 50-pin connectors (for sensors/actuators) and an RS485 port (for communication with the Mark V controller). The module is typically installed in TCC (Turbine Control Cabinet) slots for optimal integration with the backplane.

Routine maintenance involves monthly checks of the status LED (green = normal, red = fault) and quarterly cleaning of dust/debris (critical for maintaining IP65 protection). The RS485 interface supports remote diagnostic scans to identify open sensors or shorted outputs without on-site inspection. GE offers hot-swap capability for DS200TCCAG1BAA, allowing replacement without system shutdown. Backed by a 1-year warranty, the module includes 24/7 global technical support, with OEM-certified repairs restoring units to factory specifications.

Call to Action

Whether you’re optimizing turbine control, enhancing petrochemical process precision, or ensuring reliable metallurgical production, GE DS200TCCAG1BAA delivers integrated functionality, extreme durability, and flexible integration. Contact us for a customized solution tailored to your analog I/O needs, and let our expertise maximize your system’s efficiency and uptime.