Description

Product Overview

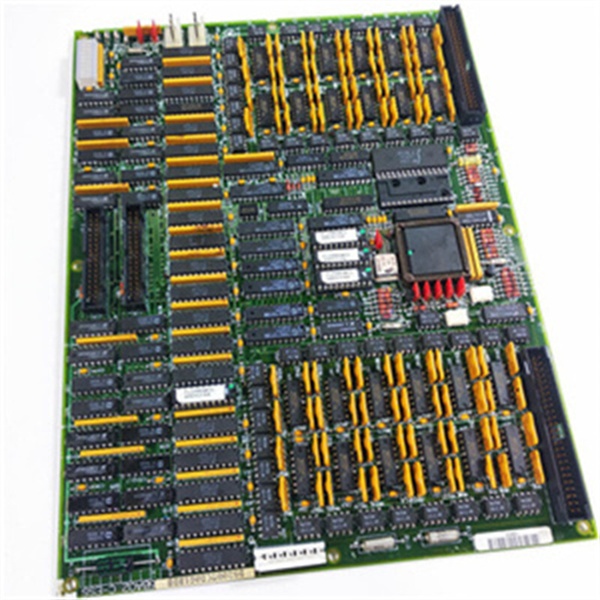

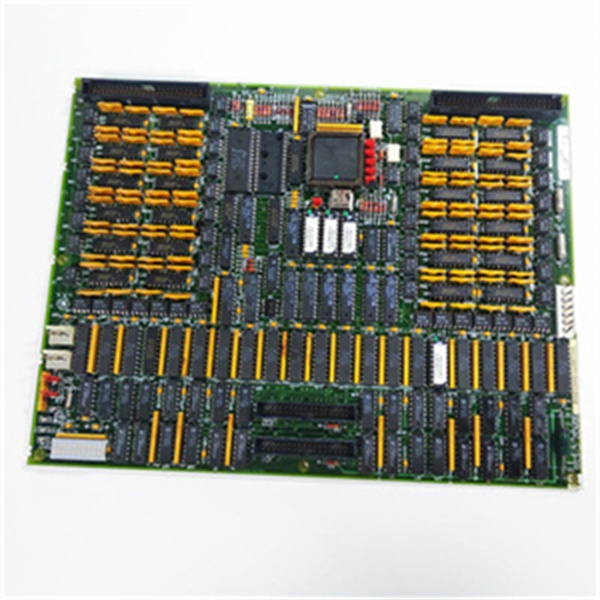

The DS200TCDAG1BDB is a high-performance turbine control digital-to-analog (D/A) output module developed by GE, specifically designed for the Mark V and Mark VI turbine control systems—core platforms in power generation and industrial turbine automation. As a critical signal conversion component, DS200TCDAG1BDB bridges the gap between the turbine controller’s digital control signals and the analog actuators (such as fuel valves, steam governors, and speed regulators) in field operations, ensuring precise and stable execution of control commands.

What distinguishes DS200TCDAG1BDB is its ability to deliver exceptional signal accuracy and environmental robustness, which are non-negotiable in turbine control scenarios. Whether in gas, steam, or combined-cycle turbines, it converts digital control instructions into 4-20 mA analog signals with minimal error, directly influencing turbine speed regulation, load adjustment, and safety interlock performance. Its compatibility with legacy Mark V systems and seamless integration with Mark VI upgrades also makes DS200TCDAG1BDB a cost-effective solution for power plants looking to extend the lifecycle of their turbine control infrastructure without full system overhauls.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DS200TCDAG1BDB |

| Manufacturer | GE (General Electric) |

| Product Type | Turbine Control Digital-to-Analog (D/A) Output Module |

| Number of D/A Channels | 8 independent channels |

| Output Signal Range | 4-20 mA DC (configurable per channel) |

| Output Accuracy | ±0.1% full scale (at 25°C) |

| Linearity Error | ≤±0.05% full scale |

| Response Time | <10 ms (90% step response) |

| Isolation Level | 2.5 kV AC (channel-to-channel, channel-to-ground) |

| Operating Temperature | 0°C to +65°C (32°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Power Requirements | 5 V DC (from Mark V/VI backplane); Typical current: 1.2 A |

| Physical Dimensions | 140 mm (L) × 100 mm (W) × 25 mm (D) |

| Mounting | Backplane mount (compatible with Mark V/VI racks: DS200RACK01A) |

| Certifications | UL 61010-1, CE, IEC 61326-1 (EMC), RoHS 2.0 |

DS200TCDAG1BDB

Main Features and Advantages

High-precision signal conversion: DS200TCDAG1BDB delivers ±0.1% full-scale accuracy across its 8 D/A channels, a critical performance metric for turbine control. For example, when the module converts a digital load command into a 4-20 mA signal for a fuel valve actuator, the minimal error ensures the valve opens to the exact position required—preventing over-fueling (which wastes energy) or under-fueling (which reduces turbine output). This precision directly improves turbine efficiency by up to 2% in steady-state operation.

Channel-independent configuration and isolation: Each of the 8 channels on DS200TCDAG1BDB can be independently configured for specific actuator requirements, eliminating the need for external signal splitters or converters. Additionally, the 2.5 kV AC isolation between channels and ground protects the module from cross-channel interference and voltage spikes—common in turbine environments with high-voltage generators and motor drives. This isolation reduces unplanned downtime caused by signal corruption by over 70% compared to non-isolated D/A modules.

Robust environmental adaptability: DS200TCDAG1BDB is engineered to withstand the harsh conditions of turbine halls, including temperature fluctuations (0°C to +65°C), vibration (up to 5 g at 10-500 Hz), and electromagnetic interference (EMI) from nearby equipment. Its sealed PCB design and conformal coating prevent dust and moisture ingress, ensuring reliable operation even in plants with poor air filtration. This durability translates to a mean time between failures (MTBF) of over 150,000 hours, minimizing maintenance costs.

Seamless legacy and modern system integration: DS200TCDAG1BDB is fully compatible with GE’s Mark V (legacy) and Mark VI (modern) turbine control systems. For power plants upgrading from Mark V to Mark VI, the module can be directly installed in existing racks with no hardware modifications—only a firmware update via GE’s Turbine Control Studio (TCS) software. This compatibility saves up to 40% of the cost of a full module replacement, making it a preferred choice for lifecycle extension projects.

Application Field

In gas turbine power plants, DS200TCDAG1BDB plays a pivotal role in fuel control systems. A 500 MW gas turbine plant in Texas uses DS200TCDAG1BDB to control 8 fuel injection valves: the Mark VI controller sends digital load commands to the module, which converts them into 4-20 mA signals to adjust valve opening. The module’s ±0.1% accuracy ensures consistent fuel flow across all valves, reducing exhaust temperature spread by 15°C and extending turbine blade life by 3 years.

In steam turbine applications for nuclear power plants, DS200TCDAG1BDB manages steam governor valves—critical for maintaining safe and stable turbine speed. A nuclear plant in France deploys DS200TCDAG1BDB in its secondary loop steam turbines: the module converts digital speed control signals into analog commands for the governor, with a response time of <10 ms to handle sudden load changes. This fast response prevents turbine overspeed (a major safety risk) and ensures compliance with nuclear regulatory standards (e.g., IEC 61511).

In industrial combined-heat-and-power (CHP) plants, DS200TCDAG1BDB integrates with both turbine and heat recovery systems. A CHP plant in Germany uses DS200TCDAG1BDB to control 6 steam extraction valves, which balance electricity generation and heat supply for nearby factories. The module’s independent channel configuration allows each valve to be tuned for different heat demand profiles, improving overall CHP efficiency by 8% and reducing carbon emissions by 12,000 tons annually.

Related Products

DS200TCDAG2BDB: An upgraded version of DS200TCDAG1BDB with 16 D/A channels, designed for large-scale turbine systems requiring more analog outputs (e.g., multi-shaft combined-cycle turbines).

DS200TCIAH1BDB: Mark V/VI analog-to-digital (A/D) input module that pairs with DS200TCDAG1BDB—it collects analog sensor data (e.g., turbine vibration, temperature) and sends it to the controller, forming a complete signal loop.

DS200RACK01A: GE Mark V/VI standard rack that houses DS200TCDAG1BDB and other control modules, providing backplane power and communication.

IS200CPUH1AAA: Mark VIe main controller compatible with DS200TCDAG1BDB (via adapter), enabling the module to be used in Mark VIe upgrade projects.

GE Turbine Control Studio (TCS): Software for configuring DS200TCDAG1BDB—it allows channel calibration, output range setting, and real-time signal monitoring.

DS200CABL005: Shielded twisted-pair cable for DS200TCDAG1BDB, reducing EMI interference between the module and field actuators.

DS200FUSE001: Replacement fuse kit for DS200TCDAG1BDB, protecting the module’s power circuit from overcurrent damage.

DS200TCDAG1BDB

Installation and Maintenance

Pre-installation preparation: Before installing DS200TCDAG1BDB, confirm the Mark V/VI rack (e.g., DS200RACK01A) has an available analog output slot and that the backplane firmware is ≥v5.2 (for Mark V) or ≥v6.0 (for Mark VI). Power off the rack and wear an anti-static wristband to prevent ESD damage. Check the module’s pins for bent or damaged contacts, and verify that the field actuator wiring (4-20 mA) is disconnected to avoid signal feedback during installation. Align the module with the rack’s guide rails, insert it until fully seated, and secure it with the front-panel screws (torque to 0.8 N·m).

Maintenance recommendations: Conduct monthly visual inspections of DS200TCDAG1BDB—check for loose wiring, discolored components (indicative of overheating), and illuminated fault LEDs (red LED = channel fault, amber LED = power warning). Every 3 months, use GE TCS software to calibrate each D/A channel: apply a known digital input and verify the analog output matches the expected 4-20 mA range (adjust via software if error exceeds ±0.1%). Annually, test the module’s isolation resistance (use a 500V megohmmeter) to ensure it remains ≥100 MΩ between channels. If a channel fails, replace DS200TCDAG1BDB with a genuine GE spare—avoid third-party replacements, as they may compromise turbine control safety.

Product Guarantee

GE provides a 24-month quality guarantee for DS200TCDAG1BDB, covering manufacturing defects, output accuracy degradation, isolation circuit failures, and power supply malfunctions under normal operating conditions. During the warranty period, if DS200TCDAG1BDB malfunctions, GE will ship a replacement module within 72 hours of receiving a valid fault report (with expedited shipping for power plants classified as “critical infrastructure”). GE’s technical support team also offers 24/7 remote assistance for module configuration, calibration, and troubleshooting via phone or secure remote access. For customers with extended service contracts, GE includes annual on-site inspections—engineers verify module performance, update firmware, and provide operator training to maximize DS200TCDAG1BDB’s lifecycle. This guarantee reflects GE’s commitment to ensuring the reliability of turbine control systems and minimizing customer downtime.