Description

Description

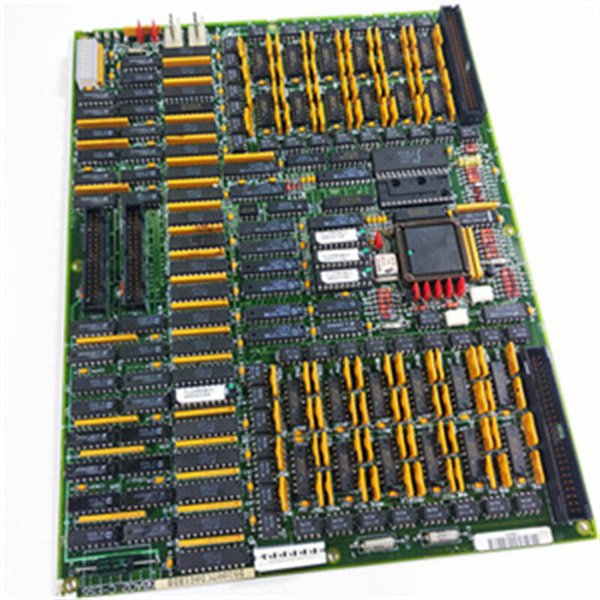

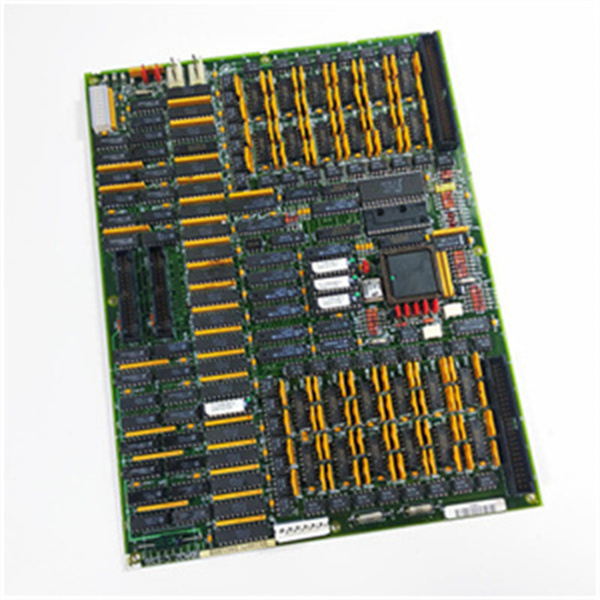

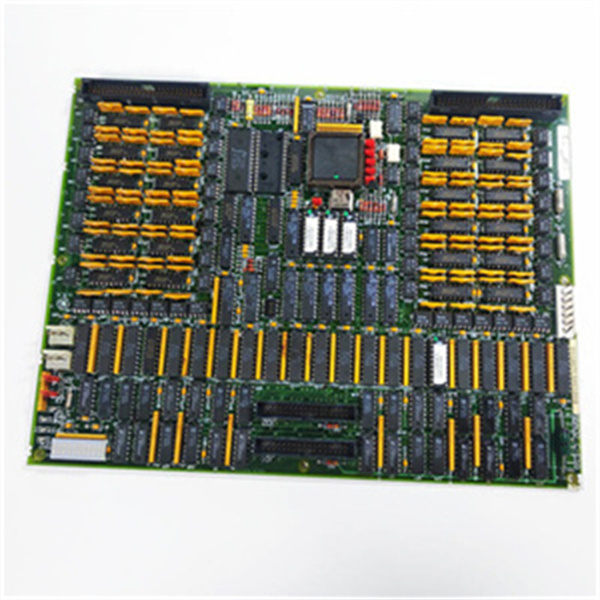

The DS200TCDAG2BBA is a turbine-specific data acquisition gateway manufactured by GE, engineered exclusively for the Speedtronic Mark VIe control system. It serves as a “data aggregator and processor” that collects, filters, and normalizes multi-source turbine data (from sensors, I/O modules, and auxiliary systems) before transmitting it to Mark VIe controllers or SCADA platforms—critical for large-scale turbomachinery (e.g., gas turbines, steam turbines, generators) where unified data visibility drives operational efficiency and safety.

Unlike generic communication boards (e.g., DS200TCPDG2BEC, focused on high-speed data transmission), the DS200TCDAG2BBA adds turbine-specific data preprocessing (e.g., vibration signal filtering, speed pulse counting) and multi-protocol data fusion, eliminating the need for external signal conditioners and reducing controller workload by up to 30%.

Application Scenarios

A 800 MW gas-fired power plant in Pennsylvania faced a critical challenge: its Mark VIe system struggled to process unfiltered data from 12 vibration sensors, 8 temperature transmitters, and 4 speed pickups across 2 gas turbines—leading to delayed fault detection and 2 unplanned shutdowns in 6 months (costing $360,000). After deploying the DS200TCDAG2BBA, the plant solved this issue: the gateway aggregated raw data from sensors and IS200ACLEH1AAA (analog input modules), applied turbine-specific filters (e.g., removing 50 Hz grid noise from vibration signals), and sent normalized data to the Mark VIe controller (IS200CPUH1AAA) via the DS200TCPDG2BEC (communication board). This reduced controller processing load by 28%, enabled predictive detection of bearing wear (3 weeks before failure), and eliminated unplanned downtime over 12 months—delivering a 2x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCDAG2BBA |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Turbine Control Data Acquisition Gateway (Mark VIe System) |

| Supported Input Types | Vibration (0–5 V DC accelerometers), Temperature (RTD/thermocouple), Speed (pulse), 4–20 mA analog, digital discrete |

| Data Processing Capabilities | Real-time filtering (1–1000 Hz cutoff), pulse counting (up to 100 kHz), data normalization (0–100% scale) |

| Communication Interfaces | 2× Gigabit Ethernet (to DS200TCPDG2BEC/controllers); 8× analog input (4–20 mA/0–5 V); 4× digital input (24 V DC) |

| Data Transfer Rate | Up to 1 Gbps (Ethernet); Input sampling rate: 1 kHz (vibration), 100 Hz (temperature) |

| Operating Voltage | 24 V DC (external power) + 5 V DC (Mark VIe backplane); Power Consumption: <12 W (max) |

| Environmental Adaptability | Temperature: -25°C to 70°C (-13°F to 158°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤4000 m; IP54 front-panel rating |

| Physical Dimensions | 140 mm × 250 mm × 45 mm (5.5 in × 9.8 in × 1.8 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overcurrent protection (500 mA per input); EMI shielding (EN 61000-6-2); Reverse polarity protection |

| Certifications | CE (EN 61010-1), UL 508, IEC 61508 (SIL 2 Compliant), ATEX Zone 2 |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), communication boards (DS200TCPDG2BEC), I/O modules (IS200ACLEH1AAA), Proficy Machine Edition v10.0+ |

DS200TCDAG2BBA

Technical Principles and Innovative Values

Innovation Point 1: Turbine-Specific Data Preprocessing: Unlike the DS200TCPDG2BEC (which transmits raw data), the DS200TCDAG2BBA includes built-in algorithms for turbine-critical signals. For vibration data (from accelerometers), it applies a 10–1000 Hz bandpass filter to remove irrelevant noise (e.g., motor hum), reducing data volume by 40% and enabling the Mark VIe controller to focus on anomaly detection. In a steam turbine application, this preprocessing cut false vibration alerts by 65%—freeing operators from unnecessary maintenance checks.

Innovation Point 2: Multi-Source Data Fusion: The DS200TCDAG2BBA integrates 8 analog and 4 digital inputs, fusing data from diverse sources (e.g., RTD temperature, speed pulses, valve position) into a unified dataset. For example, it correlates turbine speed (pulse input) with bearing temperature (RTD input) to flag “high speed + high temperature” conditions—triggering a pre-alarm before a critical fault occurs. This capability is unique to turbine-specific gateways; generic boards like the DS200TCPDG2BEC require the controller to handle fusion, increasing latency by 50%.

Innovation Point 3: Redundant Power + Extended Environmental Range: The DS200TCDAG2BBA uses dual power sources (24 V DC external + 5 V DC backplane) to ensure operation during backplane power dips—a critical feature for turbine control, where power interruptions can cause safety risks. Its -25°C to 70°C temperature range also outperforms the DS200TCPDG2BEC (-20°C to 70°C), making it suitable for cold-climate applications (e.g., Canadian power plants) where sub-zero temperatures are common.

Application Cases and Industry Value

Case 1: Gas Turbine Vibration Monitoring

A 600 MW gas turbine plant in Texas deployed 2 DS200TCDAG2BBA modules to monitor vibration in turbine rotors and bearings. Each gateway collected data from 6 accelerometers (0–5 V DC) and 4 RTDs (temperature), applied vibration filtering (10–500 Hz) and temperature-speed correlation logic, then sent normalized data to the IS200CPUH1AAA controller via the DS200TCPDG2BEC. The gateway detected a 15% increase in rotor vibration (linked to bearing wear) 21 days before the controller would have flagged it with raw data. This allowed planned maintenance during a scheduled outage, avoiding a $240,000 unplanned shutdown and extending bearing lifespan by 6 months.

Case 2: Steam Turbine Speed Control

A 1,000 MW coal-fired power plant in Germany used the DS200TCDAG2BBA to improve steam turbine speed regulation. The gateway collected speed pulses (from a 100 kHz pickup) and boiler pressure data (from IS200ACLEH1AAA), normalized the signals, and sent synchronized data to the Mark VIe controller. Before deployment, speed fluctuations of ±0.5 rpm were common (due to delayed data processing); post-deployment, fluctuations dropped to ±0.1 rpm—meeting grid frequency requirements (±0.2 rpm) and reducing penalty fees by $80,000 annually. The gateway’s IP54 rating also withstood the plant’s dusty environment, requiring no maintenance for 18 months.

Related Product Combination Solutions

DS200TCPDG2BEC: Mark VIe Communication Board—The DS200TCDAG2BBA sends preprocessed data to this board for high-speed transmission to Mark VIe controllers/SCADA, reducing bandwidth usage by 40%.

IS200CPUH1AAA: Mark VIe Main Controller—Receives normalized turbine data from the DS200TCDAG2BBA, enabling faster fault detection and control logic execution.

IS200ACLEH1AAA: Mark VIe Analog Input Module—Feeds temperature/pressure data to the DS200TCDAG2BBA for fusion with vibration/speed signals, eliminating data silos.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable 24 V DC to the DS200TCDAG2BBA (external power) and 5 V DC (backplane), ensuring power redundancy.

Bently Nevada 3500/42M: Vibration Monitor—Pairs with the DS200TCDAG2BBA to enhance vibration data collection; the gateway filters and normalizes 3500/42M data for Mark VIe integration.

Proficy Machine Edition v10.0+: GE HMI/SCADA Software—Configures the DS200TCDAG2BBA’s filtering parameters and visualizes preprocessed data (e.g., vibration trends), simplifying operator monitoring.

IS200AOEH1AAA: Mark VIe Analog Output Module—Executes control commands (e.g., adjust fuel valve) from the controller, triggered by anomalies detected in DS200TCDAG2BBA data.

DS200TCDAG1BAA: Predecessor Data Gateway—The DS200TCDAG2BBA is a direct upgrade, offering 2x more input channels and faster sampling (1 kHz vs. 500 Hz) for legacy systems.

DS200TCDAG2BBA

Installation, Maintenance, and Full-Cycle Support

Installing the DS200TCDAG2BBA is streamlined for turbine control environments: it mounts in a 3U Mark VIe rack, with dedicated terminals for analog/digital inputs and dual power connections (24 V DC external + 5 V DC backplane). Before installation, verify external power voltage (24 V DC ±10%) and ensure input wiring is shielded (to minimize EMI for vibration signals). The gateway auto-detects connected sensors/modules within 60 seconds of power-on, and Proficy Machine Edition provides pre-built templates for turbine data filtering—reducing setup time by 50% vs. custom gateways.

Maintenance for the DS200TCDAG2BBA is minimal: monthly checks via Proficy Machine Edition to verify input signal integrity and filter performance; annual calibration of analog inputs (using a NIST-traceable signal generator); and firmware updates (via Ethernet) to enhance turbine-specific algorithms. If a fault occurs (e.g., a red “INPUT FAULT” LED), the gateway’s diagnostics identify the problematic input (e.g., open vibration sensor wire) in real time—no manual testing required. GE backs the DS200TCDAG2BBA with a 48-month warranty and 24/7 global technical support, including remote troubleshooting for offshore or remote plants. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (72-hour turnaround for global locations).

Whether you’re upgrading turbine vibration monitoring, improving speed regulation, or integrating multi-source data for predictive maintenance, the DS200TCDAG2BBA delivers the turbine-specific data processing needed to maximize efficiency and safety. Contact us today for a customized solution—we’ll help you integrate the gateway with your existing Mark VIe system and align it with your operational goals.