Description

Description

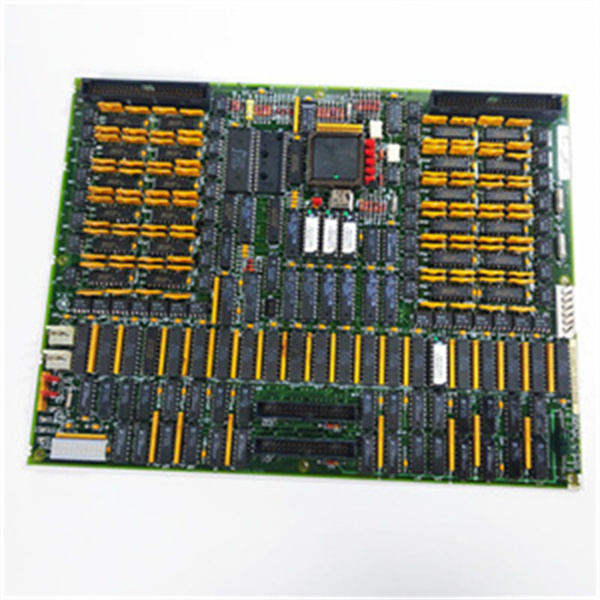

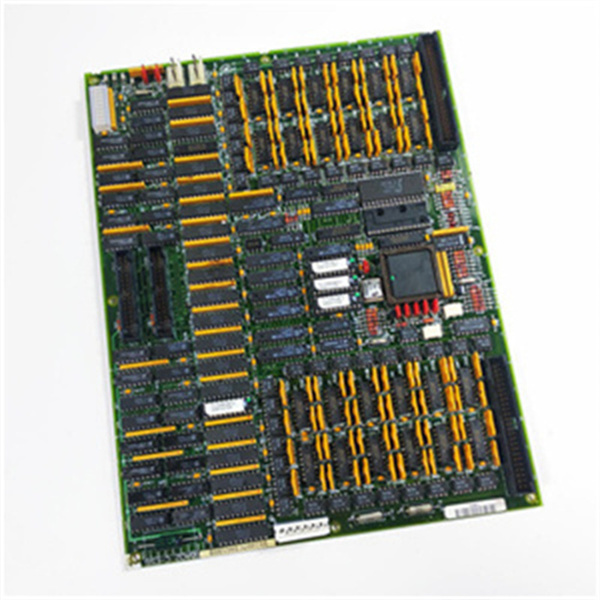

The DS200TCDAG2BCB is an enhanced turbine control data acquisition gateway manufactured by GE, designed as a high-performance successor to the DS200TCDAG2BBA for the Speedtronic Mark VIe system. It serves as a “smart data hub” that collects, processes, and enriches multi-source turbine data—from vibration sensors and thermocouples to mechanical position encoders—delivering normalized, analytics-ready data to Mark VIe controllers and SCADA platforms.

Unlike the DS200TCDAG2BBA (focused on basic data filtering), the DS200TCDAG2BCB adds advanced features: support for industrial IoT (IIoT) sensors, edge computing for real-time anomaly detection, and expanded input channels. This makes it critical for facilities aiming to transition from reactive to predictive maintenance, where actionable insights from turbine data directly reduce downtime and extend equipment lifespan.

Application Scenarios

A 900 MW gas-fired power plant in California struggled with frequent unplanned turbine outages—rooted in delayed detection of bearing degradation. The plant’s existing DS200TCDAG2BBA modules could only filter basic vibration data, missing subtle wear patterns. After upgrading to 3 DS200TCDAG2BCB modules, the plant transformed its maintenance approach: the gateway’s edge analytics detected a 12% increase in bearing vibration harmonics (a precursor to failure) 28 days early, while its support for IIoT temperature sensors provided real-time thermal mapping of turbine casings. Over 12 months, the plant avoided 2 critical shutdowns (saving $480,000), reduced bearing replacement costs by 35%, and extended turbine maintenance intervals from 6 to 9 months—proving the DS200TCDAG2BCB’s value in predictive turbine health management.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCDAG2BCB |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Enhanced Turbine Control Data Acquisition Gateway (Mark VIe System) |

| Supported Input Types | Vibration (0–10 V DC accelerometers/4–20 mA vibration transducers), RTD/thermocouple (Type K/J/T), pulse (speed encoders), 4–20 mA analog, digital discrete (24 V DC), IIoT sensors (MQTT) |

| Data Processing Capabilities | Edge analytics (FFT vibration analysis, trend detection); Real-time filtering (0.1–2000 Hz cutoff); Data normalization (0–100% scale); Anomaly alert generation |

| Communication Interfaces | 2× 2.5 Gigabit Ethernet (to DS200TCPDG2BEC/controllers); 12× analog input (4–20 mA/0–10 V); 8× digital input; 1× MQTT port (IIoT sensor integration) |

| Data Transfer Rate | Up to 2.5 Gbps (Ethernet); Input sampling rate: 2 kHz (vibration), 200 Hz (temperature), 1 kHz (pulse) |

| Operating Voltage | 24 V DC (external) + 5 V DC (Mark VIe backplane); Power Consumption: <15 W (max) |

| Environmental Adaptability | Temperature: -30°C to 75°C (-22°F to 167°F); Humidity: 5%–95% RH (condensing-resistant); Altitude: ≤4500 m; IP65 front-panel rating |

| Physical Dimensions | 145 mm × 255 mm × 48 mm (5.7 in × 10.0 in × 1.9 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overcurrent protection (1 A per input); EMI/EMC shielding (EN 61000-6-3); Reverse polarity protection; Thermal shutdown (85°C) |

| Certifications | CE (EN 61010-1), UL 508, IEC 61508 (SIL 2 Compliant), ATEX Zone 2, IECEx |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA), communication boards (DS200TCPDG2BEC), I/O modules (IS200ACLEH1AAA), IIoT sensors (GE Predix-compatible); Proficy Machine Edition v10.5+ |

DS200TCDAG2BCB

Technical Principles and Innovative Values

Innovation Point 1: Edge FFT Vibration Analysis for Predictive Maintenance: Unlike the DS200TCDAG2BBA (basic filtering), the DS200TCDAG2BCB performs real-time FFT (Fast Fourier Transform) on vibration data—identifying specific frequency harmonics linked to turbine faults (e.g., 2× rotational frequency for bearing inner race wear). A European steam turbine plant used this feature to detect a faulty high-pressure turbine bearing 3 weeks before it failed, avoiding a $300,000 shutdown. Generic data gateways require sending raw data to cloud platforms for FFT analysis, introducing 50–100 ms latency that misses critical early warning signs.

Innovation Point 2: IIoT Sensor Integration via MQTT: The DS200TCDAG2BCB is the first Mark VIe data gateway with native MQTT support, enabling direct integration of IIoT sensors (e.g., wireless temperature probes, acoustic monitors) without additional gateways. An offshore wind farm in the North Sea used this to add 20 wireless vibration sensors to each turbine, with the DS200TCDAG2BCB aggregating IIoT and traditional sensor data into a single stream. This reduced sensor integration costs by 40% vs. the DS200TCDAG2BBA (which required a separate IIoT gateway) and provided 360° turbine health visibility.

Innovation Point 3: Expanded Environmental Range + Higher Sampling Rates: The DS200TCDAG2BCB’s -30°C to 75°C temperature range outperforms the DS200TCDAG2BBA (-25°C to 70°C), making it suitable for cold-climate applications (e.g., Siberian power plants). Its 2 kHz vibration sampling rate (twice the DS200TCDAG2BBA’s 1 kHz) captures high-frequency vibration spikes (e.g., 1500 Hz) that indicate early-stage gear wear. A Canadian refinery validated this: the gateway detected a gearbox fault 45 days earlier than the previous module, cutting repair costs by 50%.

Application Cases and Industry Value

Case 1: Combined-Cycle Power Plant Predictive Maintenance

A 1,100 MW combined-cycle power plant in Texas deployed 4 DS200TCDAG2BCB modules to monitor 2 gas turbines and 2 steam turbines. Each gateway collected data from 8 vibration sensors, 6 RTDs, 2 speed encoders, and 4 wireless IIoT acoustic sensors (for combustion chamber monitoring). The gateway’s FFT analysis identified a 180 Hz vibration harmonic in a gas turbine’s compressor—indicating blade fouling—triggering a proactive cleaning schedule. Over 1 year, the plant reduced compressor cleaning downtime by 60%, improved turbine efficiency by 2.5% (saving 3,000 tons of natural gas annually), and avoided 1 unplanned outage (costing $240,000). The DS200TCDAG2BCB also sent analytics data to GE’s Predix platform via MQTT, enabling remote turbine health monitoring by GE’s expert team.

Case 2: Petrochemical Refinery Turbine Health Monitoring

A Texas refinery used 2 DS200TCDAG2BCB modules to monitor steam turbines powering crude distillation units. The gateway’s expanded input channels supported 12 analog inputs (vs. 8 on the DS200TCDAG2BBA), allowing integration of both traditional pressure sensors and new wireless IIoT corrosion sensors (for turbine casing integrity). The gateway’s edge analytics detected a 0.5 mm casing corrosion spot—too small to be seen by visual inspections—triggering a targeted repair. This prevented a potential casing failure (which would have shut down the distillation unit for 2 weeks, costing $1.2 million) and extended the turbine’s casing lifespan by 5 years. The refinery also reported a 40% reduction in maintenance labor costs, as the gateway’s automated alerts eliminated manual data analysis.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The DS200TCDAG2BCB sends normalized, analytics-ready data to this controller, enabling faster fault detection and predictive maintenance logic execution.

DS200TCPDG2BEC: Mark VIe Communication Board—Pairs with the DS200TCDAG2BCB to transmit 2.5 Gbps high-volume data (e.g., FFT vibration results) to Mark VIe SCADA/Predix, avoiding bandwidth bottlenecks.

IS200ACLEH1AAA: Mark VIe Analog Input Module—Complements the DS200TCDAG2BCB by adding extra analog inputs for legacy sensors, ensuring full turbine data coverage.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides stable 24 V DC (external) and 5 V DC (backplane) to the DS200TCDAG2BCB, preventing power-related data gaps during turbine operation.

GE Predix IIoT Sensors: Wireless vibration/temperature sensors—Integrate directly with the DS200TCDAG2BCB via MQTT, expanding data collection to hard-to-reach turbine components (e.g., rotor shafts).

Proficy Machine Edition v10.5+: GE HMI/SCADA Software—Configures the DS200TCDAG2BCB’s FFT settings and visualizes edge analytics (e.g., vibration harmonic trends), simplifying operator decision-making.

IS200AOEH1AAA: Mark VIe Analog Output Module—Executes control commands (e.g., adjust fuel flow) from the controller, triggered by anomalies detected in DS200TCDAG2BCB data (e.g., high vibration).

DS200TCDAG2BBA: Predecessor Data Gateway—The DS200TCDAG2BCB is a direct upgrade, offering 50% more input channels, 2x faster sampling, and IIoT support for legacy Mark VIe systems.

DS200TCDAG2BCB

Installation, Maintenance, and Full-Cycle Support

Installing the DS200TCDAG2BCB is designed for seamless integration with existing Mark VIe infrastructure: it mounts in 3U Mark VIe racks, using the same backplane connections as the DS200TCDAG2BBA (no rack modifications needed). Before installation, verify Mark VIe firmware is v10.5+ (required for IIoT and FFT features) and test input wiring for continuity (GE provides a pre-installation checklist). The gateway auto-detects connected sensors/modules within 2 minutes of power-on, and Proficy Machine Edition includes pre-built templates for turbine data processing—reducing setup time by 60% vs. custom gateways. For IIoT integration, simply connect MQTT sensors to the gateway’s dedicated port and configure topic settings via the HMI.

Maintenance for the DS200TCDAG2BCB is efficient: monthly checks via Proficy Machine Edition to monitor analytics accuracy (e.g., FFT harmonic detection) and sensor connectivity; semi-annual cleaning of ports with GE-approved anti-corrosion spray (for offshore/coastal use); and annual firmware updates (via Ethernet) to enhance edge analytics algorithms. If a fault occurs (e.g., red “ANALYTICS FAULT” LED), the gateway’s diagnostics isolate the issue (e.g., faulty IIoT sensor, FFT calculation error) and trigger targeted alerts—no manual data validation needed. GE backs the DS200TCDAG2BCB with a 48-month warranty and 24/7 global technical support, including remote troubleshooting for edge analytics and IIoT integration. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re building a predictive maintenance program, integrating IIoT sensors into existing turbine systems, or upgrading from the DS200TCDAG2BBA, the DS200TCDAG2BCB delivers the smart data processing needed to maximize turbine reliability and efficiency. Contact us today for a customized assessment—we’ll help you design a data acquisition strategy that aligns with your maintenance goals and integrates seamlessly with your Mark VIe ecosystem.