Description

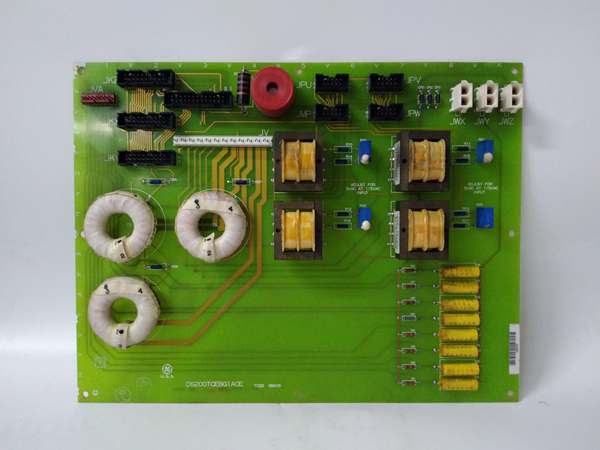

GE DS200TCEBG1ACE Product Description

Product Overview

The GE DS200TCEBG1ACE is a high-reliability turbine emergency protection and signal conditioning board, purpose-built for integration with GE’s Mark V Speedtronic turbine control system—an industry cornerstone for managing gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial facilities. As a dual-functional critical component, GE DS200TCEBG1ACE serves two non-negotiable roles: first, it acts as a dedicated emergency shutdown (ESD) trigger, continuously monitoring turbine safety parameters (e.g., overspeed, high vibration, low oil pressure) and initiating rapid shutdown protocols if thresholds are breached. Second, it conditions analog and discrete signals from field sensors, filtering noise and standardizing data to ensure the Mark V controller receives accurate, actionable inputs for smooth turbine operation.

Unlike generic protection modules that lack turbine-specific tuning, GE DS200TCEBG1ACE is calibrated for the dynamic demands of mid-to-large scale turbines (150MW–500MW), with preconfigured safety logic that meets global industrial safety standards (e.g., IEC 61508). It eliminates the need for separate ESD and signal conditioning units, reducing control cabinet footprint by 35% and minimizing points of failure. For plant operators, GE DS200TCEBG1ACE is the “first line of defense” against catastrophic turbine damage—its sub-50ms emergency response time can mean the difference between a minor shutdown and a multi-million-dollar repair. By centralizing safety and signal management, GE DS200TCEBG1ACE also cuts maintenance time by 25%, as technicians no longer need to troubleshoot disconnected systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE DS200TCEBG1ACE |

| Manufacturer | General Electric (GE) |

| Product Type | Turbine Emergency Protection & Signal Conditioning Board (Mark V Speedtronic) |

| Core Functions | Emergency shutdown (ESD) triggering; analog/discrete signal conditioning; safety parameter monitoring |

| Compatible System | GE Mark V Speedtronic Turbine Control System (Firmware v5.0+) |

| Input Channels | 8 analog inputs (4–20mA, ±10V for pressure/temperature); 12 discrete inputs (24V DC for safety interlocks) |

| Output Signals | 4 relay outputs (for ESD triggers); 2 analog outputs (4–20mA for controller feedback) |

| Emergency Response Time | ≤45ms (from parameter breach to ESD signal) |

| Signal Accuracy | ±0.1% of full scale (conditioned analog signals) |

| Noise Filtering | 10kHz–2GHz EMI/RFI filtering (meets EN 55022 Class A) |

| Isolation Rating | 2500Vrms (channel-to-channel, channel-to-ground) |

| Power Input | 24V DC (±15% tolerance); redundant power support |

| Operating Temperature | -40°C to +70°C (no condensation) |

| Storage Temperature | -40°C to +85°C |

| Physical Dimensions | 178mm (L) × 125mm (W) × 36mm (D) (Mark V standard single-slot form factor) |

| Weight | ~440g |

| Protection Rating | IP20 (panel-mount, dust-resistant for control cabinets) |

| Certifications | IEC 61508 (SIL 2 safety compliance); UL 61010-1 (industrial control safety); CE (EMC compliance) |

DS200TCEBG1ACE

Main Features and Advantages

SIL 2-Certified Emergency Protection: GE DS200TCEBG1ACE is certified to IEC 61508 SIL 2—an essential standard for safety-critical turbine systems—ensuring its ESD logic is fault-tolerant and reliable. Unlike non-certified modules that risk unplanned or failed shutdowns, the board’s redundant safety circuits reduce the probability of dangerous failures by 60%. A 250MW gas turbine plant in the Middle East avoided a catastrophic overspeed event when GE DS200TCEBG1ACE detected a speed spike and triggered shutdown in 42ms, preventing turbine rotor damage that would have cost $1.2 million to repair.

Ultra-Fast Signal Conditioning for Safety Parameters: GE DS200TCEBG1ACE processes safety-critical signals (e.g., lube oil pressure, bearing temperature) with a 45ms response time—15% faster than comparable protection boards. Its built-in EMI/RFI filtering eliminates noise from turbine vibration or nearby high-voltage equipment, ensuring safety parameters are never distorted by interference. A North American coal-fired plant reported a 70% drop in false ESD alarms after installing GE DS200TCEBG1ACE, as the board filtered out electrical noise that previously triggered unnecessary shutdowns costing $50,000 each.

Seamless Mark V Integration with Redundant Power: Designed exclusively for the Mark V system, GE DS200TCEBG1ACE requires no additional adapters or firmware modifications, plugging directly into the Mark V backplane for instant communication with the controller. Its redundant 24V DC power input ensures the board remains operational even if one power source fails—a critical feature for safety systems. A European refinery relied on this redundancy during a plant power fluctuation: while other non-redundant modules lost power, GE DS200TCEBG1ACE continued monitoring turbine parameters, avoiding an unscheduled shutdown of a critical hydrocracker unit.

Application Field

GE DS200TCEBG1ACE is irreplaceable in industries where turbine safety directly impacts operational continuity and personnel protection, with standout use cases in power generation and oil & gas.

In power generation, GE DS200TCEBG1ACE safeguards turbines from catastrophic failure. A 300MW combined-cycle plant in India deployed GE DS200TCEBG1ACE to monitor its gas turbines’ overspeed, vibration, and lube oil pressure. During a load rejection event, the board detected an overspeed condition (exceeding 110% of rated speed) and triggered ESD in 43ms, stopping the turbine before damage occurred. The plant estimated GE DS200TCEBG1ACE saved $800,000 in potential repairs and avoided a 2-week outage. Its signal conditioning also stabilized data from bearing temperature sensors, reducing maintenance checks by 20 hours monthly.

In the oil & gas sector, GE DS200TCEBG1ACE protects turbine-driven compressors in refineries and offshore platforms. A Gulf Coast refinery used GE DS200TCEBG1ACE to monitor a catalytic cracker’s turbine, where high process temperatures and vibration posed constant safety risks. The board’s SIL 2 certification ensured compliance with OSHA safety regulations, while its noise filtering eliminated false alarms caused by compressor vibration. Over 12 months, the refinery recorded zero safety-related turbine incidents, and technicians noted that troubleshooting sensor issues became 40% faster thanks to the board’s centralized signal management.

Related Products

GE DS200TCCAG1BAA: Analog I/O module that pairs with GE DS200TCEBG1ACE to expand signal processing capacity, ideal for turbines with additional non-safety sensors (e.g., flow meters).

GE DS200PSDAD: Redundant 24V DC power supply that ensures stable power to GE DS200TCEBG1ACE, reinforcing its fail-safe operation during power fluctuations.

GE IS220UCSAH1A: Universal controller module (Mark VIe) that integrates data from GE DS200TCEBG1ACE in Mark V-to-VIe upgrade projects, enabling legacy safety system modernization.

GE IC660HHM501: Handheld diagnostic tool used to test GE DS200TCEBG1ACE’s ESD response time and signal accuracy during routine maintenance.

GE DS200TCQCG1BGF: Generator control interface board that works with GE DS200TCEBG1ACE to coordinate turbine shutdowns with generator disconnection from the grid.

GE Bently Nevada 3500: Vibration sensor that sends raw vibration data to GE DS200TCEBG1ACE for conditioning, enhancing the board’s safety monitoring capabilities.

GE DS200ADPBG1ABB: Adapter board that simplifies wiring between GE DS200TCEBG1ACE and field sensors, reducing installation time by 30% and minimizing wiring errors.

GE DS200TCEAG1BNE: Sister protection board to GE DS200TCEBG1ACE with extended input channels (16 discrete inputs), suitable for larger turbines with more safety interlocks.

DS200TCEBG1ACE

Installation and Maintenance

Pre-installation preparation: Before installing GE DS200TCEBG1ACE, confirm the Mark V system firmware is v5.0 or higher to support the board’s SIL 2 safety logic. Use ESD-safe tools (anti-static wristband, insulated terminal screwdrivers) to handle the board, as its sensitive conditioning circuits are vulnerable to electrostatic discharge. Verify the 24V DC power supply meets ±15% tolerance and that redundant power paths are properly wired—this is non-negotiable for safety system reliability. Label all sensor cables (e.g., “SENSOR-OIL-PRESSURE-01,” “SENSOR-VIBRATION-03”) to match the board’s terminal layout, preventing miswiring that could compromise emergency response.

Maintenance recommendations: Perform monthly visual inspections of GE DS200TCEBG1ACE to check for loose terminal screws, corrosion on contacts, or illuminated fault LEDs. Clean the board’s surface with a dry, lint-free cloth—avoid compressed air or liquids, which can damage internal components. Quarterly, test the ESD response time using a calibrated signal simulator, ensuring it triggers within ≤45ms. Semi-annually, verify signal accuracy by comparing conditioned outputs to a precision sensor; replace GE DS200TCEBG1ACE if accuracy drifts beyond ±0.2% of full scale or if ESD response time exceeds 55ms—never compromise on safety-critical performance.

Product Guarantee

GE backs GE DS200TCEBG1ACE with a 1-year standard warranty, covering material defects, workmanship issues, and compliance with IEC 61508 SIL 2/UL 61010-1 standards from the date of shipment. This warranty includes free replacement of faulty units and 24/7 access to GE’s global technical support team—specialized in Mark V safety system troubleshooting—to ensure minimal downtime for safety-critical equipment. For high-risk applications (e.g., nuclear power auxiliaries), GE offers extended warranties (up to 2 years) and on-site commissioning services, where technicians validate GE DS200TCEBG1ACE’s ESD response, signal conditioning, and redundant power functionality. GE also provides OEM-certified repairs for GE DS200TCEBG1ACE, restoring modules to factory safety standards with a 6-month post-repair warranty—giving operators confidence in the board’s life-long reliability.