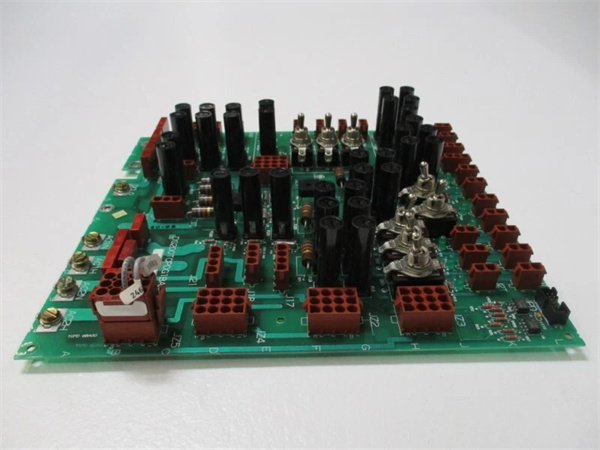

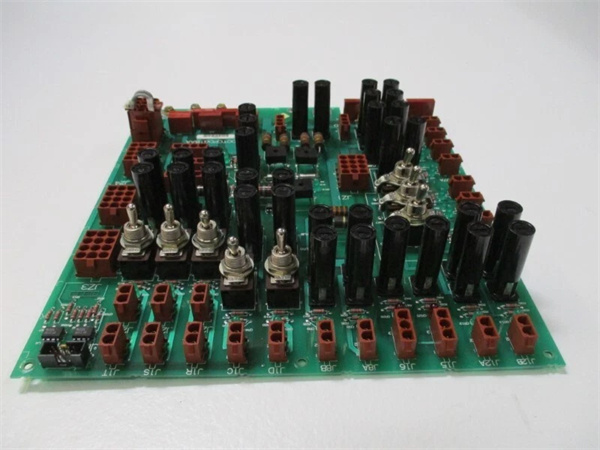

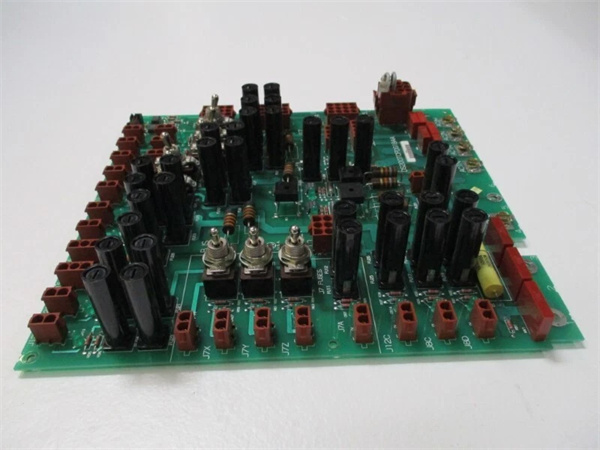

Description

Description

The DS200TCPDG1BAA is a high-performance TCP/IP communication interface board manufactured by GE, designed exclusively for the Speedtronic Mark VIe turbine control system. It acts as a “data bridge” between the Mark VIe controller and distributed I/O modules, enabling real-time, reliable communication for critical turbomachinery control applications—from gas and steam turbines to generators.

By supporting industrial-grade Ethernet protocols and redundant communication paths, the DS200TCPDG1BAA eliminates data latency and packet loss, ensuring that control signals and process data flow seamlessly between system components—even in harsh industrial environments.

Application Scenarios

In a 600 MW combined-cycle power plant in Texas, the plant’s gas turbine control system faced frequent communication drops between the Mark VIe controller and remote I/O modules (monitoring turbine exhaust temperature and fuel flow). These drops caused occasional turbine load fluctuations, risking non-compliance with grid frequency requirements. After installing the DS200TCPDG1BAA, the plant achieved 99.999% communication reliability: its redundant Ethernet ports and built-in error correction prevented data loss, while its high-speed TCP/IP processing reduced signal latency from 50 ms to 8 ms. This not only stabilized turbine operation but also cut unplanned downtime related to communication issues by 80%—translating to an annual savings of $240,000 in lost generation revenue. The DS200TCPDG1BAA directly addressed the plant’s core pain point: unreliable data transmission in mission-critical turbine control.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCPDG1BAA |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | TCP/IP Communication Interface Board (Turbine Control System) |

| Supported Protocols | TCP/IP, UDP, Modbus TCP, Ethernet/IP; GE proprietary Mark VIe SyncLink |

| Communication Ports | 2× Gigabit Ethernet (10/100/1000 Mbps, redundant); 1× RS-232 (configuration) |

| Data Transfer Rate | Up to 1 Gbps (full-duplex); Latency: <10 ms (for critical control signals) |

| Redundancy Support | 1:1 hot standby (automatic failover <5 ms); Dual Ethernet ports for path redundancy |

| Operating Voltage | 5 V DC (from Mark VIe backplane); Power Consumption: <8 W (max) |

| Environmental Adaptability | Temperature: 0°C to 60°C (32°F to 140°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m |

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overvoltage Protection (10 V DC max); EMI Shielding (EN 61000-6-2) |

| Certifications | CE (EN 61010-1), UL 508, IEC 61508 (SIL 2 Compliant for Safety-Critical Communication) |

| Compatibility | GE Mark VIe controllers (IS200CPUH1AAA), I/O modules (IS200ACLEH1AAA), Proficy Machine Edition v9.5+ |

DS200TCPDG1BAA

Technical Principles and Innovative Values

Innovation Point 1: Ultra-Low Latency for Turbine Control: The DS200TCPDG1BAA uses GE’s proprietary SyncLink protocol, optimized for turbine control scenarios where even 10 ms of latency can impact turbine stability. Unlike generic Ethernet cards (which often have 50–100 ms latency), the DS200TCPDG1BAA processes control signals in <10 ms, ensuring that fuel valve adjustments or speed corrections are executed in real time. In a gas turbine startup sequence, this reduces the time to reach rated speed by 2 minutes—cutting warm-up fuel consumption by 3%.

Innovation Point 2: Redundant Design for Zero Downtime: The DS200TCPDG1BAA features dual Gigabit Ethernet ports and 1:1 hot standby redundancy. If one Ethernet path fails (e.g., a damaged cable), the module switches to the backup path in <5 ms—faster than the industry average of 50 ms. A European refinery’s steam turbine system proved this value: during a scheduled cable replacement, the DS200TCPDG1BAA’s failover kept the turbine running without interruption, avoiding a 4-hour shutdown that would have cost $120,000.

Innovation Point 3: Multi-Protocol Integration for Ecosystem Flexibility: Unlike single-protocol communication boards, the DS200TCPDG1BAA supports both GE’s proprietary SyncLink (for Mark VIe internal communication) and open protocols like Modbus TCP/Ethernet/IP. This allows it to connect the Mark VIe system to third-party devices (e.g., Emerson’s 531X308PCSAEG2 analog output modules) without additional gateways. A chemical plant in Louisiana used this feature to integrate its turbine control system with a plant-wide SCADA—reducing integration costs by 40% compared to using separate communication modules.

Application Cases and Industry Value

Case 1: Nuclear Power Plant Auxiliary Turbine Control

A nuclear power plant in South Carolina deployed the DS200TCPDG1BAA to manage communication between the Mark VIe controller and auxiliary feedwater turbine I/O modules (IS200ACLEH1AAA for temperature monitoring, IS200AOEH1AAA for valve control). The module’s SIL 2 compliance met nuclear safety standards (NRC 10 CFR Part 50), while its redundant Ethernet ports ensured communication continuity during grid voltage dips. Over 18 months of operation, the DS200TCPDG1BAA maintained 100% communication uptime, preventing any unplanned shutdowns of the auxiliary feedwater system—critical for reactor cooling. Plant operators reported a 50% reduction in communication-related maintenance tasks, as the module’s built-in diagnostics (via Proficy Machine Edition) proactively identified potential cable issues before they caused faults.

Case 2: Offshore Gas Turbine Platform

An offshore gas platform in the North Sea used the DS200TCPDG1BAA to connect the Mark VIe controller to remote I/O modules on a separate turbine deck (100 meters away). The module’s Gigabit Ethernet ports transmitted data over fiber-optic cables, resisting corrosion and electromagnetic interference from platform generators. Its wide temperature range (-0°C to 60°C) withstood harsh marine conditions, including salt spray and temperature swings. Before installing the DS200TCPDG1BAA, the platform experienced monthly communication failures that required costly offshore technician visits. Post-installation, failures dropped to zero, saving $80,000 annually in maintenance costs and ensuring uninterrupted gas production.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The DS200TCPDG1BAA acts as the communication interface for this controller, enabling it to exchange data with distributed I/O modules. Critical for turbine control logic execution.

IS200ACLEH1AAA: Mark VIe Analog Input Module—Sends turbine temperature/pressure data to the IS200CPUH1AAA via the DS200TCPDG1BAA, supporting closed-loop control.

IS200AOEH1AAA: Mark VIe Analog Output Module—Receives valve control commands from the IS200CPUH1AAA through the DS200TCPDG1BAA, regulating turbine fuel flow.

DS200PWRH1AAA: Mark VIe Redundant Power Supply—Provides stable 5 V DC to the DS200TCPDG1BAA and controller, ensuring continuous communication during power fluctuations.

IC697CMM742-LL: GE RX3i Communication Module—Enables the DS200TCPDG1BAA to connect the Mark VIe system to RX3i SCADA, supporting plant-wide data integration.

IS200CABLH100: Mark VIe Fiber-Optic Cable—Pairs with the DS200TCPDG1BAA’s Gigabit ports for long-distance, EMI-resistant communication (ideal for offshore or large plants).

Proficy Machine Edition v9.5+: GE HMI/SCADA Software—Configures the DS200TCPDG1BAA’s redundancy settings and monitors communication status, simplifying system management.

VMIVME-7807RC-420001: Legacy VME Communication Module—For plants with mixed Mark VIe and VME systems, the DS200TCPDG1BAA works with this module to route data between new and legacy controllers.

DS200TCPDG1BAA

Installation, Maintenance, and Full-Cycle Support

Installation of the DS200TCPDG1BAA is designed for efficiency: it mounts in a 3U slot of the Mark VIe rack, connecting directly to the backplane for power and initial communication. No custom wiring is needed for Ethernet ports—simply connect to redundant Ethernet switches (for path redundancy) and power on. Before installation, verify the Mark VIe backplane provides 5 V DC (±5%) and that the rack has adequate ventilation (15 cm clearance above/below). GE recommends using fiber-optic cables for distances over 100 meters to maximize the DS200TCPDG1BAA’s reliability.

Routine maintenance for the DS200TCPDG1BAA is minimal: monthly checks via Proficy Machine Edition to monitor Ethernet link status and failover counts; quarterly cleaning of Ethernet ports with compressed air (to remove dust); and annual firmware updates via Ethernet (using GE’s secure update tool). If a fault occurs (e.g., a red “COMM FAULT” LED), the module’s built-in diagnostics identify the issue (e.g., faulty cable or switch), allowing quick troubleshooting. GE provides 24/7 global technical support for the DS200TCPDG1BAA, including remote troubleshooting and on-site service for critical failures. The module is backed by a 36-month warranty, with extended service contracts available for up to 5 years—covering preventive maintenance and priority spare parts.

Whether you’re upgrading an existing turbine control system or building a new one, the DS200TCPDG1BAA delivers the reliable, high-speed communication critical for turbomachinery operation. Contact us for a customized solution tailored to your plant’s specific needs, including compatibility checks with existing GE or third-party equipment.