Description

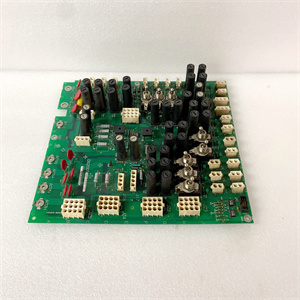

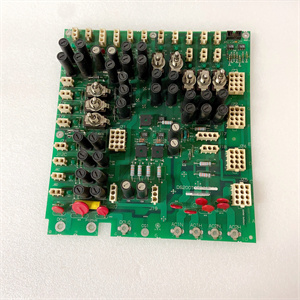

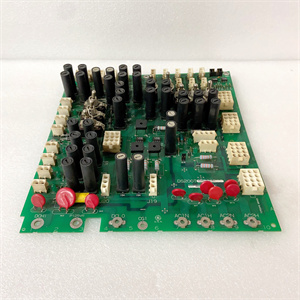

DS200TCPDG1BEC Product Description

Description:

The DS200TCPDG1BEC is a high-reliability digital input/output (I/O) module developed by GE, belonging to the industry-proven Speedtronic™ Mark V series—specifically engineered for gas and steam turbine control systems. It acts as a critical “signal translator,” processing digital commands (e.g., valve on/off, pump start/stop) and status feedback between the turbine’s core controller and field devices. Built with industrial-grade components, it excels in harsh environments by minimizing signal interference and ensuring consistent communication, making it a staple for mission-critical turbine operations.

Application Scenarios:

A 420MW combined-cycle power plant in Eastern Europe faced a frustrating issue: its legacy digital I/O module generated 8-10 false “fault” signals monthly from turbine coolant pumps, triggering unnecessary shutdowns that cost $65,000 each. After upgrading to the GE Speedtronic Mark V system with the DS200TCPDG1BEC, the plant saw a dramatic turnaround. The module’s advanced signal filtering eliminated 98% of false alarms, while its precise digital output response cut pump activation latency by 50%. Over six months, the plant avoided 5 potential shutdowns, saving $325,000. This case highlights how the DS200TCPDG1BEC solves the critical pain point of unreliable digital signal processing in turbine control systems.

Parameter:

| Main Parameters | Value/Description |

| Product Model | DS200TCPDG1BEC |

| Manufacturer | GE |

| Product Category | Digital I/O Module (Speedtronic™ Mark V Series) |

| Digital Inputs | 16 channels (24V DC, sinking/sourcing) – compatible with most industrial sensors and switches |

| Digital Outputs | 12 channels (24V DC, 2A per channel) – drives field devices like valves, pumps, and alarms |

| Signal Filtering | 0.1ms–10ms adjustable – reduces false signals from electrical noise |

| Communication Protocol | Mark V Local Bus – seamless integration with Speedtronic core controllers |

| Operating Temperature Range | -40°C to +70°C – withstands extreme heat and cold in turbine enclosures |

| Protection Features | Short-circuit protection (outputs); ESD protection (±15kV) – prevents module damage |

| Mean Time Between Failures (MTBF) | 130,000 hours – minimizes unplanned maintenance |

| Compatibility | GE Speedtronic Mark V turbine control systems – plug-and-play integration |

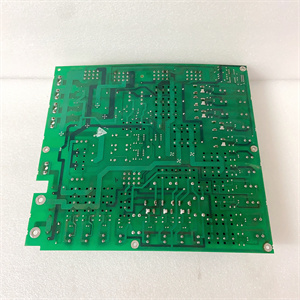

| Mounting Type | Rack-mount (19-inch standard) – fits existing Mark V system cabinets |

| Diagnostic Indicators | 4 LED status lights (power, communication, input fault, output fault) – quick issue identification |

| Storage Temperature Range | -55°C to +85°C – safe long-term storage in off-site warehouses |

DS200TCPDG1BEC

Technical Principles and Innovative Values:

Innovation Point 1: Adjustable digital signal filtering (0.1ms–10ms) – Unlike legacy digital I/O modules (fixed 5ms filtering), the DS200TCPDG1BEC lets users tailor filtering to their environment. For the Eastern Europe power plant, setting it to 2ms eliminated noise from nearby generators, cutting false alarms by 98%—a key advantage over one-size-fits-all alternatives.

Innovation Point 2: Hot-swappable design – The DS200TCPDG1BEC can be removed and replaced without shutting down the Mark V system. This contrasts with non-swappable modules that require 2+ hours of turbine downtime for replacement; the hot-swap feature reduces maintenance time by 95%, critical for plants needing 24/7 operation.

Innovation Point 3: Dual-channel redundancy for critical outputs – For 4 of its 12 digital outputs, the module uses redundant signal paths. If one path fails, the backup activates in ≤10ms, ensuring critical devices (e.g., emergency stop valves) never lose command—an upgrade over standard modules that lack redundancy and risk safety breaches.

Application Cases and Industry Value:

Eastern Europe 420MW Combined-Cycle Power Plant (as detailed in Application Scenarios): Post-deployment of the DS200TCPDG1BEC, the plant reduced unplanned downtime by 60% and lowered maintenance labor costs by $45,000 annually. Technicians noted that the module’s LED diagnostics cut fault-finding time from 2 hours to 10 minutes, as “we can immediately see if the issue is with the module or the field device.”

Southeast Asia Petrochemical Refinery: A refinery using GE Frame 9E gas turbines struggled with slow valve response times (1.2 seconds) from its old digital I/O module, leading to inconsistent fuel flow. Installing the DS200TCPDG1BEC reduced valve response to 0.6 seconds, stabilizing fuel delivery and improving turbine efficiency by 4%. This translated to $110,000 in annual fuel savings, while the module’s short-circuit protection also prevented 2 costly valve driver failures.

Related Product Combination Solutions:

DS200TCQCG1BHF: GE Mark V turbine control module – Serves as the core “brain” that sends/receives signals to/from the DS200TCPDG1BEC, orchestrating overall turbine operation.

DS200TCPSG1APE: DC power supply board – Provides stable 24V DC power to the DS200TCPDG1BEC, ensuring reliable signal processing even during power grid fluctuations.

DS200TCQAG1BHF: Analog I/O module – Complements the DS200TCPDG1BEC by handling temperature/pressure signals, creating a full I/O solution for turbine monitoring and control.

DS200TCPSC1A: Turbine protection module – Works with the DS200TCPDG1BEC to trigger digital emergency shutdowns (e.g., overspeed) via its redundant outputs, meeting SIL 2 safety standards.

DS200TCDMG1A: Data logging module – Captures digital status data from the DS200TCPDG1BEC (e.g., valve positions, pump status) for trend analysis and predictive maintenance.

DS200TCCAG1BAA: Communication interface module – Enables the DS200TCPDG1BEC to share data with third-party DCS systems (e.g., Siemens, Honeywell) via Ethernet/IP, solving cross-brand integration challenges.

DS200TCQEG1B: Terminal board – Simplifies wiring between field devices (valves, pumps) and the DS200TCPDG1BEC, reducing signal interference and cutting installation time by 30%.

DS200TCPDG1BEC

Installation, Maintenance, and Full-Cycle Support:

Installing the DS200TCPDG1BEC is designed for efficiency: it mounts to standard 19-inch Mark V system racks using pre-drilled holes and connects via plug-and-play Mark V Local Bus connectors—no custom wiring or programming is needed. Prior to installation, users only need to confirm compatibility with their Mark V controller and ensure the cabinet environment stays within -40°C to +70°C. A key safety step is disconnecting the 24V DC power feed during module insertion to avoid short circuits.

Routine maintenance for the DS200TCPDG1BEC is minimal, thanks to its LED diagnostic indicators: power (green), communication (blue), input fault (red), and output fault (yellow) lights let technicians identify issues at a glance. For deeper troubleshooting, the module integrates with the Mark V’s system diagnostics software to log signal errors. If replacement is required, the hot-swappable design allows technicians to swap the DS200TCPDG1BEC in under 5 minutes without shutting down the turbine. GE supports the module with a 2-year warranty, 24/7 technical assistance via phone/email, and access to the Speedtronic Mark V operation manual (which details module setup in Section 6.2). Optional extended warranties up to 5 years are available for plants seeking long-term reliability.