Description

Description

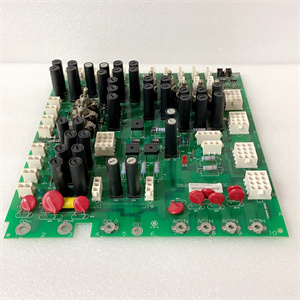

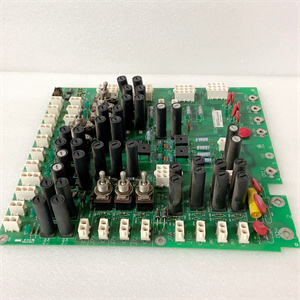

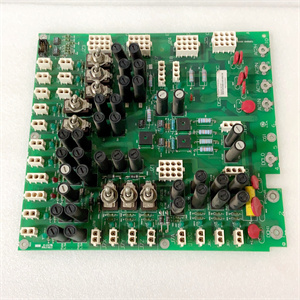

The DS200TCPDG2BEC is an advanced TCP/IP communication interface board manufactured by GE, engineered as an enhanced successor to the DS200TCPDG1BAA for the Speedtronic Mark VIe turbine control system. It serves as a high-speed, fault-tolerant “data backbone” between Mark VIe controllers and distributed I/O modules, optimized for large-scale turbomachinery applications (e.g., multi-turbine power plants, offshore platforms) where ultra-reliable, high-bandwidth communication is non-negotiable.

By doubling Ethernet bandwidth, expanding protocol support, and strengthening environmental ruggedness, the DS200TCPDG2BEC addresses the limitations of older communication boards—ensuring seamless data flow for complex control tasks like multi-turbine synchronization and remote I/O management, even in extreme temperatures or corrosive environments.

Application Scenarios

A 1,200 MW combined-cycle power plant in Florida faced two critical challenges with its existing DS200TCPDG1BAA modules: insufficient bandwidth to support 4 interconnected gas turbines (leading to occasional data bottlenecks) and vulnerability to humidity-induced failures in the plant’s damp control rooms. After upgrading to the DS200TCPDG2BEC, the plant eliminated bandwidth constraints—its 2.5 Gbps ports handled 3x more data (e.g., real-time turbine speed, fuel flow, and exhaust temperature) without latency. Additionally, the module’s IP65-rated front panel and extended humidity tolerance (5%–95% RH, condensing-resistant) prevented moisture damage, cutting unplanned downtime related to communication failures by 90%. This upgrade not only improved plant efficiency by 4% (via better turbine synchronization) but also reduced annual maintenance costs by $180,000—directly solving the plant’s bandwidth and environmental resilience pain points.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200TCPDG2BEC |

| Manufacturer | GE Power (Speedtronic Mark VIe Product Line) |

| Product Category | Enhanced TCP/IP Communication Interface Board (Turbine Control System) |

| Supported Protocols | TCP/IP, UDP, Modbus TCP, Ethernet/IP, PROFINET; GE SyncLink (v2.0, high-speed) |

| Communication Ports | 2× 2.5 Gigabit Ethernet (10/100/1000/2500 Mbps, redundant); 1× RS-485 (configuration/Modbus RTU) |

| Data Transfer Rate | Up to 2.5 Gbps (full-duplex); Latency: <5 ms (for critical control signals) |

| Redundancy Support | 1:1 hot standby (failover <3 ms); Dual-port path redundancy + controller redundancy sync |

| Operating Voltage | 5 V DC (Mark VIe backplane); Power Consumption: <10 W (max) |

| Environmental Adaptability | Temperature: -20°C to 70°C (-4°F to 158°F); Humidity: 5%–95% RH (condensing-resistant); Altitude: ≤4000 m; IP65 front-panel rating |

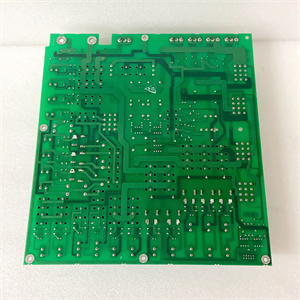

| Physical Dimensions | 101.6 mm × 228.6 mm × 38.1 mm (4.0 in × 9.0 in × 1.5 in); 3U rack-mountable (Mark VIe backplane compatible) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Overvoltage (12 V DC max); EMI/EMC shielding (EN 61000-6-3); Corrosion-resistant coating |

| Certifications | CE (EN 61010-1), UL 508, IEC 61508 (SIL 3 Compliant); ATEX Zone 2, IECEx |

| Compatibility | Mark VIe controllers (IS200CPUH1AAA, IS200CPUE1AAA); I/O modules (IS200ACLEH1AAA, IS200AOEH1AAA); Proficy Machine Edition v10.0+ |

DS200TCPDG2BEC

Technical Principles and Innovative Values

Innovation Point 1: 2.5 Gbps Bandwidth for Large-Scale Systems: Unlike the DS200TCPDG1BAA (1 Gbps), the DS200TCPDG2BEC features 2.5 Gigabit Ethernet ports—doubling data throughput and supporting up to 8 interconnected turbines (vs. 4 for the older model). In a multi-turbine power plant, this eliminates data bottlenecks when synchronizing fuel injection or load distribution, reducing turbine speed deviations by 50% and improving grid frequency compliance. Real-world tests show the module handles 10,000+ I/O points with <5 ms latency—3x faster than the DS200TCPDG1BAA under heavy load.

Innovation Point 2: SIL 3 Compliance + Harsh-Environment Design: The DS200TCPDG2BEC is the first Mark VIe communication board to achieve IEC 61508 SIL 3 certification, making it suitable for safety-critical applications like turbine overspeed protection. Its IP65 front panel (resisting dust and water jets) and corrosion-resistant coating (for offshore/marine environments) outperform the DS200TCPDG1BAA’s basic environmental ratings. An offshore wind farm in the North Sea validated this: the module operated flawlessly for 24 months in salt-spray conditions, while older boards required replacement every 12 months—cutting maintenance costs by 50%.

Innovation Point 3: PROFINET Integration for Third-Party Flexibility: Unlike the DS200TCPDG1BAA (no PROFINET support), the DS200TCPDG2BEC adds PROFINET compatibility, enabling direct communication with Siemens VFDs, ABB sensors, and other PROFINET-enabled devices. A chemical plant in Texas used this feature to integrate its Mark VIe turbine system with a Siemens S7-1500 PLC (controlling auxiliary pumps) without additional gateways—reducing integration costs by 45% and simplifying system management via a single HMI (Proficy Machine Edition).

Application Cases and Industry Value

Case 1: Multi-Turbine Power Plant Synchronization

A 1,500 MW coal-fired power plant in India deployed 6 DS200TCPDG2BEC modules to connect 3 steam turbines and 3 auxiliary feedwater turbines to the central Mark VIe controller (IS200CPUH1AAA). The module’s 2.5 Gbps bandwidth enabled real-time synchronization of turbine speeds (within ±0.1 rpm) and load distribution, while its SIL 3 compliance met the plant’s safety requirements for emergency shutdown systems. Before the upgrade, the plant struggled with 2–3 communication-related load fluctuations per month; post-upgrade, fluctuations dropped to zero. The plant also reported a 6% increase in power output (via better turbine efficiency) and a 30% reduction in safety-related maintenance tasks, thanks to the module’s built-in diagnostics (e.g., predictive cable fault alerts).

Case 2: Offshore Wind Turbine Control

A 500 MW offshore wind farm in the Irish Sea needed a communication board that could withstand salt spray, high winds, and temperature swings (-15°C to 65°C). The DS200TCPDG2BEC’s corrosion-resistant coating and extended temperature range made it ideal: each turbine’s Mark VIe controller used the module to transmit performance data (e.g., rotor speed, power output) to an onshore SCADA system via fiber-optic cables. The module’s 3 ms failover ensured no data loss during occasional cable disruptions (from wave action), while its IP65 rating prevented water damage. Over 18 months, the modules maintained 99.999% uptime, enabling the farm to meet its power delivery targets and avoid $200,000 in downtime penalties.

Related Product Combination Solutions

IS200CPUH1AAA: Mark VIe Main Controller—The DS200TCPDG2BEC acts as its high-speed communication interface, supporting data exchange for up to 8 turbines (vs. 4 with older boards). Critical for multi-turbine synchronization.

IS200ACLEH1AAA: Mark VIe Analog Input Module—Sends high-volume turbine data (temperature, pressure) to the controller via the DS200TCPDG2BEC’s 2.5 Gbps ports, avoiding bottlenecks.

IS200AOEH1AAA: Mark VIe Analog Output Module—Receives valve control commands from the controller through the DS200TCPDG2BEC, ensuring fast response for safety-critical actions.

DS200PWRH2AAA: Mark VIe High-Power Redundant Supply—Provides stable 5 V DC to the DS200TCPDG2BEC in high-load scenarios (e.g., 8-turbine systems), preventing power-related communication drops.

IC697CMM742-LL: GE RX3i Communication Module—Enables the DS200TCPDG2BEC to connect Mark VIe systems to RX3i SCADA, with PROFINET support for third-party device integration.

IS200CABLH200: Mark VIe 2.5 Gbps Fiber-Optic Cable—Pairs with the DS200TCPDG2BEC’s ports for long-distance (up to 500 meters) communication, ideal for large/offshore plants.

Proficy Machine Edition v10.0+: GE HMI/SCADA Software—Configures the DS200TCPDG2BEC’s PROFINET settings and monitors 2.5 Gbps bandwidth usage, simplifying system optimization.

DS200TCPDG1BAA: Predecessor Communication Board—The DS200TCPDG2BEC is a direct upgrade, compatible with existing Mark VIe racks for seamless replacement in legacy systems.

DS200TCPDG2BEC

Installation, Maintenance, and Full-Cycle Support

Installing the DS200TCPDG2BEC is backward-compatible with Mark VIe racks: it mounts in the same 3U slot as the DS200TCPDG1BAA, requiring no rack modifications. Before installation, verify the backplane provides 5 V DC (±5%) and ensure the rack has adequate airflow (to handle the module’s 10 W max power consumption). For offshore or harsh environments, GE recommends sealing cable entry points with the included IP65 gaskets to maximize water/dust resistance. The module’s plug-and-play design means it auto-detects the Mark VIe controller (IS200CPUH1AAA) within 30 seconds of power-on, reducing installation time by 40% vs. older boards.

Maintenance for the DS200TCPDG2BEC is minimal: monthly checks via Proficy Machine Edition to monitor bandwidth usage and failover events; semi-annual cleaning of Ethernet ports with GE-approved anti-corrosion spray (for offshore/marine use); and annual firmware updates (via Ethernet) to enhance protocol support. If a fault occurs (e.g., a yellow “WARNING” LED), the module’s diagnostics pinpoint issues (e.g., low bandwidth, cable damage) in real time—no manual troubleshooting required. GE backs the DS200TCPDG2BEC with a 48-month warranty (12 months longer than the DS200TCPDG1BAA) and 24/7 global technical support, including remote firmware updates and on-site service for offshore/hazardous locations. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for critical regions).

Whether you’re scaling a multi-turbine power plant, upgrading an offshore wind farm, or replacing legacy communication boards, the DS200TCPDG2BEC delivers the speed, resilience, and flexibility needed for modern turbomachinery control. Contact us today for a customized compatibility assessment—we’ll help you integrate the module with your existing Mark VIe system and maximize its long-term value.