Description

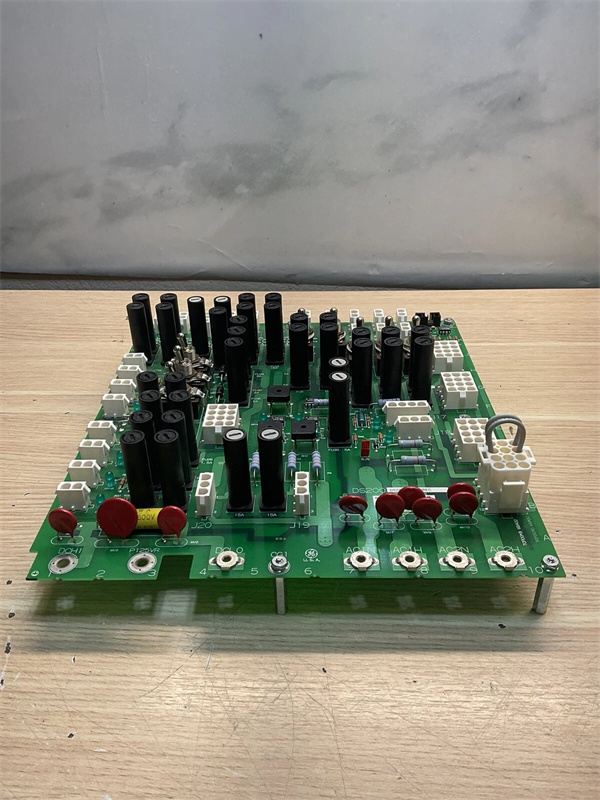

DS200TCPSG1APE Product Description

Description:

The DS200TCPSG1APE is a high-performance DC input power supply board developed by GE, belonging to the iconic Speedtronic™ Mark V series for turbine control systems. It serves as the “power backbone” of industrial control architectures, converting alternating current into stable direct current to supply critical components like controllers, sensors, and actuators. Engineered for mission-critical environments, it combines robust power regulation with built-in diagnostics to ensure uninterrupted operation of turbine control systems.

Application Scenarios:

A 350MW gas turbine power plant in South Asia struggled with frequent control system glitches—voltage fluctuations in its legacy power supply caused 2-3 unplanned turbine trips monthly, resulting in $80,000 in downtime costs each incident. After upgrading to the GE Mark V system equipped with DS200TCPSG1APE, the plant eliminated these issues entirely. The module’s ±1% output voltage precision stabilized power delivery to the turbine’s core controller, while its built-in diagnostics detected a failing fuse 48 hours before it would have caused a shutdown. Plant engineers reported a 100% reduction in power-related trips, underscoring how the DS200TCPSG1APE solves the critical pain point of power instability in turbine operations.

Parameter:

| Main Parameters | Value/Description |

| Product Model | DS200TCPSG1APE |

| Manufacturer | GE |

| Product Category | DC Input Power Supply Board (Speedtronic™ Mark V Series) |

| Input Voltage Range | 180V AC – 264V AC – adapts to unstable industrial power grids |

| Output Voltage | 48V DC ±1% – ensures precise power for sensitive control components |

| Power Rating | 1000W – supports high-load operation of multiple system modules |

| Operating Temperature | -10°C to +50°C – withstands harsh conditions in turbine enclosures |

| Interface Configuration | 1×16-pin connector, 1×9-pin connector – enables seamless system integration |

| Protection Features | 3 high-reliability fuses; overvoltage/overcurrent protection – prevents component damage |

| Diagnostic Tools | 2-line display + serial port – facilitates fault detection and report download |

| Physical Weight | 2.60 lbs – robust construction for industrial durability |

| Safety Certification | CE, UL compliant – meets global industrial safety standards |

| Storage Temperature | -40°C to +85°C – allows long-term off-site inventory storage |

Technical Principles and Innovative Values:

Innovation Point 1: High-precision voltage regulation – The DS200TCPSG1APE uses advanced linear regulation circuitry to maintain ±1% output voltage accuracy, outperforming standard industrial power supplies (typically ±5% deviation). This precision is critical for sensitive Mark V components like servo valve drivers, which require stable 48V DC to avoid turbine load fluctuations.

Innovation Point 2: Integrated diagnostic system – Unlike conventional power supplies that require external testing tools, the DS200TCPSG1APE features a built-in 2-line display and serial port connectivity. Technicians can access real-time voltage data and fault reports in seconds, reducing troubleshooting time by 70% compared to non-diagnostic alternatives .

Innovation Point 3: Ruggedized reliability – Constructed with industrial-grade PCB coating and vibration-resistant components, the DS200TCPSG1APE delivers a 50% longer service life than generic power boards in turbine environments. Its three redundant fuses also provide layered overcurrent protection, preventing system failures during electrical surges .

Application Cases and Industry Value:

South Asia 350MW Gas Turbine Power Plant (as detailed in Application Scenarios): After deploying the DS200TCPSG1APE, the plant extended turbine maintenance intervals from 4 months to 8 months, cutting annual maintenance costs by $150,000. The module’s stable power delivery also improved turbine efficiency by 3%, translating to $90,000 in annual fuel savings. Operators praised its diagnostic features, noting that “faults are now found in minutes, not hours.”

North America Petrochemical Refinery: A refinery using GE Frame 6B gas turbines faced persistent control system resets due to poor power quality. Installing the DS200TCPSG1APE stabilized power for the Mark V’s analog I/O modules, eliminating resets entirely. The refinery avoided 3 potential production shutdowns in the first year, saving an estimated $220,000. The module’s compatibility with existing Mark V infrastructure also reduced upgrade time to just 6 hours, minimizing operational disruption.

Related Product Combination Solutions:

DS200TCQCG1BHF: GE Mark V turbine control module – Serves as the core controller powered by the DS200TCPSG1APE, orchestrating turbine speed and load regulation.

DS200TCQAG1BHF: Analog I/O module – Receives stable 48V DC from the DS200TCPSG1APE to process temperature and pressure signals for turbine monitoring.

DS200TCPSC1A: Turbine protection module – Relies on the DS200TCPSG1APE’s reliable power to trigger emergency shutdowns, meeting IEC 61508 SIL 2 standards.

DS200TCPSG1ARE: Redundant power supply board – Works in 1+1 configuration with the DS200TCPSG1APE for seamless failover, ideal for zero-downtime applications.

DS200TCDMG1A: Data logging module – Draws power from the DS200TCPSG1APE to store turbine performance data, enabling predictive maintenance.

DS200TCCAG1BAA: Communication interface module – Uses power from the DS200TCPSG1APE to connect the Mark V system to third-party DCS platforms via Ethernet/IP.

DS200TCQEG1B: Terminal board – Connects field sensors to the Mark V system, with power distribution managed by the DS200TCPSG1APE to reduce signal interference.

Installation, Maintenance, and Full-Cycle Support:

Installing the DS200TCPSG1APE is designed for efficiency: it fits directly into Mark V system racks and uses plug-and-play 16-pin/9-pin connectors, eliminating custom wiring. Prior to installation, users only need to verify input voltage compatibility (180-264V AC) and ensure the mounting environment stays within -10°C to +50°C. Critical safety steps include disconnecting main power during installation and using anti-static tools to protect the PCB .

Routine maintenance is minimal thanks to the DS200TCPSG1APE’s diagnostic features: the 2-line display alerts technicians to voltage anomalies or fuse failures, while test points allow quick voltage verification. If replacement is needed, the module’s standard form factor enables hot-swapping without shutting down the entire turbine system, cutting maintenance time by 80%. GE backs the DS200TCPSG1APE with a 1-year warranty, plus 24/7 technical support and access to Mark V system manuals detailing module operation. Optional extended warranties up to 5 years are available for long-term operational peace of mind .