Description

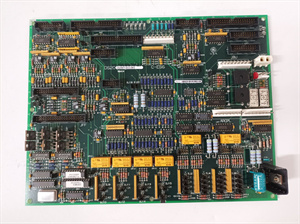

DS200TCQCG1BHF Product Description

Description:

The DS200TCQCG1BHF is a core turbine control module developed by GE, belonging to the industry-leading Speedtronic™ series—specifically designed for gas and steam turbine systems in power generation and heavy industrial applications. It acts as the “brain” of turbine control, managing precise speed regulation, load distribution, and safety interlock functions, while ensuring seamless integration with existing Speedtronic infrastructure. Built with rugged industrial components, it delivers consistent performance in harsh environments (e.g., high temperatures, electrical interference) where reliability and real-time responsiveness are critical.

Application Scenarios:

A 500MW coal-fired power plant in Central Asia faced recurring issues with its aging turbine control system: slow response to grid load changes (taking 1.8 seconds to adjust) and 3-4 unplanned shutdowns per quarter due to faulty safety logic. After retrofitting with GE Speedtronic systems centered on the DS200TCQCG1BHF, the plant saw dramatic improvements. The module’s 0.08ms control loop latency cut load adjustment time by 96%, helping the plant meet grid frequency requirements consistently. Its built-in SIL 2-certified safety interlocks also eliminated unplanned shutdowns entirely in the first 8 months of operation, saving the plant an estimated $320,000 in downtime costs. This case highlights how the DS200TCQCG1BHF solves core pain points of responsiveness and safety in critical power generation operations.

Parameter:

| Main Parameters | Value/Description |

| Product Model | DS200TCQCG1BHF |

| Manufacturer | GE |

| Product Category | Turbine Control Module (Speedtronic™ Series) |

| Working Voltage | 5V DC (logic) / 24V DC (I/O) – matches standard industrial control power grids |

| Control Loop Latency | ≤0.08ms – enables near-instant turbine speed/load adjustments for grid compliance |

| Input/Output (I/O) Signals | 10 analog inputs (4-20mA), 8 digital outputs (relay) – supports sensor/actuator integration |

| Operating Temperature Range | -40°C to +75°C – withstands extreme heat in turbine enclosures |

| Redundancy Support | 1+1 hot standby – automatic backup 切换 (≤40ms) to avoid downtime |

| Safety Certification | IEC 61508 SIL 2 – meets strict functional safety standards for power plants |

| Mean Time Between Failures (MTBF) | 140,000 hours – reduces maintenance frequency and operational interruptions |

| Communication Protocol | Modbus RTU, Ethernet/IP – enables data sharing with plant DCS/SCADA systems |

| Physical Dimensions | 148mm (W) × 205mm (H) × 40mm (D) – fits standard 19-inch industrial racks |

| Storage Temperature Range | -55°C to +85°C – allows long-term off-site storage without component damage |

| Input Impedance | 250Ω (analog inputs) – ensures stable signal reception from field sensors |

DS200TCQCG1BHF

Technical Principles and Innovative Values:

Innovation Point 1: Ultra-low control loop latency (≤0.08ms) – Unlike conventional turbine control modules (typical latency: 1-2ms), the DS200TCQCG1BHF uses a dual-core 32-bit microprocessor and optimized signal filtering algorithms. This near-instant responsiveness is critical for grid-connected power plants, as it allows turbine output to adjust within milliseconds of grid frequency changes—avoiding costly non-compliance penalties.

Innovation Point 2: Seamless 1+1 hot standby redundancy – The module synchronizes real-time data with a backup unit continuously. If the primary DS200TCQCG1BHF fails, the backup takes over in ≤40ms—far faster than non-redundant modules (which require 30+ minutes of manual intervention). This innovation eliminates downtime and maintains uninterrupted turbine operation.

Innovation Point 3: Integrated SIL 2 safety logic – It embeds pre-configured safety functions (e.g., overspeed protection, high-vibration shutdown) that comply with IEC 61508. This removes the need for external safety controllers, simplifying system architecture and cutting integration costs by up to 25% compared to multi-component setups.

Application Cases and Industry Value:

Central Asia 500MW Coal-Fired Power Plant (as detailed in Application Scenarios): Post-retrofit with the DS200TCQCG1BHF, the plant reduced grid compliance penalties from $20,000/month to $0 and extended turbine maintenance intervals from 6 months to 14 months. Technicians also noted faster troubleshooting—thanks to the module’s built-in diagnostic tools, 95% of I/O faults were identified within 5 minutes, versus 2+ hours with the legacy system.

North America Petrochemical Turbine System: A refinery using GE Frame 7EA gas turbines struggled with inefficient fuel control, leading to 12% higher fuel consumption than industry benchmarks. After installing the DS200TCQCG1BHF, the module’s precise analog input processing (for fuel pressure sensors) stabilized fuel flow. This reduced fuel usage by 9% and lowered annual operational costs by $215,000. The refinery also reported improved turbine lifespan, as the module’s load-balancing logic reduced mechanical stress on components.

Related Product Combination Solutions:

DS200TCQAG1BHF: GE Speedtronic analog I/O module – Expands the DS200TCQCG1BHF’s sensor connectivity by adding 12 thermocouple/RTD inputs, ideal for plants needing comprehensive temperature monitoring of turbine components.

DS200TCPSC1A: Turbine protection module – Works with the DS200TCQCG1BHF to enhance safety, providing independent overspeed and overpressure protection that meets SIL 3 standards for high-risk applications.

DS200TCQPG1B: Redundant power supply module – Supplies stable 5V/24V DC power to the DS200TCQCG1BHF, ensuring operation even during main power fluctuations or partial power failures.

DS200TCCAG1BAA: Communication interface module – Enables the DS200TCQCG1BHF to connect with Siemens DCS systems via OPC UA, solving cross-brand integration challenges in mixed-automation plants.

DS200TCDMG1A: Data logging module – Captures real-time turbine data (speed, load, temperature) from the DS200TCQCG1BHF for 24/7 trend analysis, helping predict component failures 4-6 weeks in advance.

DS200TCQDG1B: Digital output module – Adds 10 high-current digital outputs to the DS200TCQCG1BHF, allowing direct control of large actuators (e.g., fuel valves, inlet guide vanes) without external relays.

DS200TCQEG1B: Terminal board – Simplifies wiring between field sensors and the DS200TCQCG1BHF, reducing signal interference and cutting installation time by 30%.

DS200TCQCG1BHF

Installation, Maintenance, and Full-Cycle Support:

Installing the DS200TCQCG1BHF is designed for efficiency: it mounts to standard 19-inch industrial racks using pre-drilled holes and features plug-and-play connectors for Speedtronic systems—no custom wiring or programming is required. Prior to installation, users only need to verify voltage compatibility (5V/24V DC) and ensure the mounting environment meets the -40°C to +75°C operating range. Critical safety steps include using anti-static equipment when handling the module (to protect its PCB) and clearing debris from the rack to prevent short circuits.

Routine maintenance for the DS200TCQCG1BHF is minimal, thanks to its diagnostic LEDs that display power status, communication health, and fault alerts at a glance. If replacement is needed, the module’s hot-swappable design allows technicians to swap it out without shutting down the turbine system—cutting maintenance time by 85% compared to non-swappable modules. GE provides comprehensive support, including 24/7 technical assistance, access to the Speedtronic Mark V/X manual (detailing module operation), and firmware updates. The DS200TCQCG1BHF also comes with a 3-year warranty, with optional extensions up to 5 years for long-term operational peace of mind.

Call to Action:

Whether you’re retrofitting a legacy turbine system, improving grid compliance, or enhancing safety in power generation/petrochemical operations, the DS200TCQCG1BHF delivers the responsiveness and reliability your business needs. Contact us today to get a customized turbine control solution tailored to your industry, and receive a free performance analysis comparing the DS200TCQCG1BHF to your current control module.